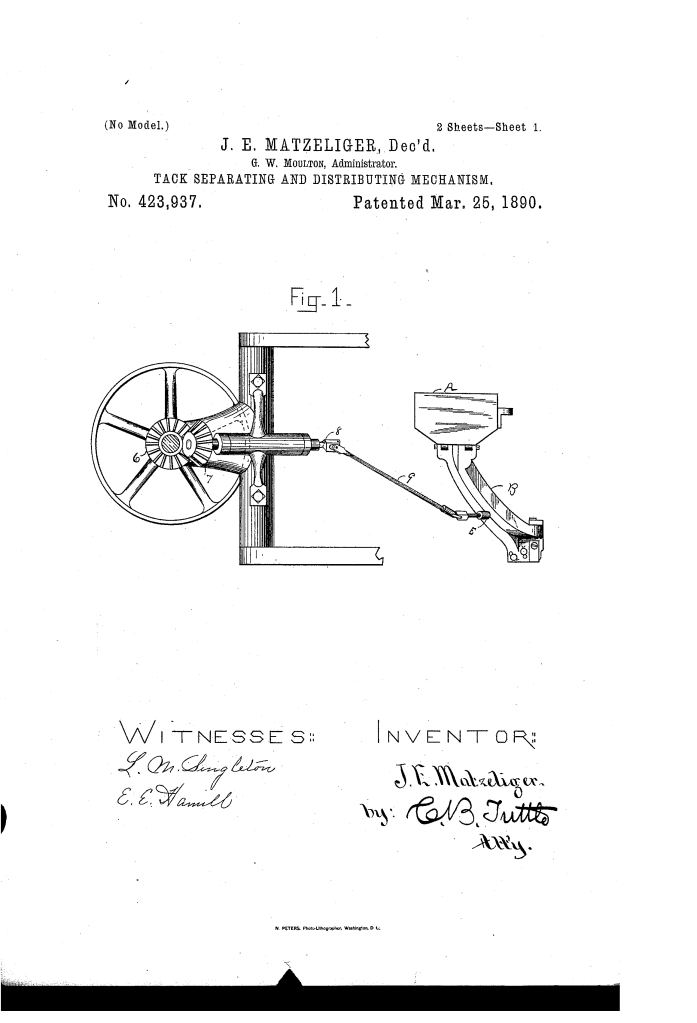

Tack Separating and Distributing Mechanism (Jan Ernst Matzeliger, No. 423,937)

The patent, filed by the administrator of the deceased inventor Jan Ernst Matzeliger, describes a mechanism for receiving tacks in bulk, separating them, and distributing them one at a time at precise intervals. This mechanism was a component part of a larger lasting-machine (a machine used in shoemaking).

Invention and Mechanism

The core of the invention is an elegantly designed spiral separator screw working at the end of an inclined chute.

- Tack Supply and Chute (B):

- Tacks are loaded in bulk into a hopper (A).

- They are transferred to the raceway channel (a) of the inclined chute (B).

- Function: Tacks are suspended in the raceway, heads resting on the chute, bodies projected downward, and they gravitate downward toward the separator.

- Spiral Separator:

- Separator-Screw: A shaft with a spirally-formed thread that is situated at the lower end of the chute, alongside a guide or guard (X).

- Thread Profile: The thread starts small at point (h) and gradually increases in diameter. Crucially, it is designed to gradually contract in diameter at the engaging point (h) so it can work up to and engage close under the head of the tack without cramping.

- Presser-Foot (e): Located over the raceway at the engaging point, this foot prevents the tack from being lifted by the screw as it grabs the tack, but it yields upwardly to prevent undue cramping.

- Operation (Separation):

- Tacks slide down the chute and wait at the entrance of the separator.

- Each complete revolution of the screw brings an open channel into position to receive the foremost tack of the line.

- As the screw turns, the thread comes in behind the tack, separating it from the row and carrying it forward, guided between the screw and the guide (X).

- Interruption: The same thread simultaneously cuts off approach for all other tacks until the revolution is complete, guaranteeing a positive interval for each tack discharge.

- Adjustment and Discharge:

- Bushing (E): The separator-shaft is journaled in a screw-threaded bushing (E). By turning this bushing, the separator can be adjusted longitudinally (forward or backward) relative to the end of the raceway slot, allowing fine-tuning of the engaging position.

- Discharge: By each complete revolution, one tack is discharged from the opposite end of the screw’s channel. The discharged tack falls to a suitable receiver (or “at random”).

Historical Significance and the Inventor

The patent is a posthumous grant, filed by the administrator of the deceased inventor, Jan Ernst Matzeliger (1852–1889).

- The Inventor (Jan Ernst Matzeliger): Matzeliger was an African-American inventor born in Suriname (Dutch Guiana). After moving to the U.S. and working in shoe factories, he developed a series of revolutionary machines. His greatest contribution was his 1883 lasting machine (patented in 1885), which this tack mechanism was designed to feed.

- Impact on Industry (Shoemaking): Matzeliger’s lasting machine and this supporting tack mechanism are historically paramount. Prior to his work, the crucial process of “lasting” a shoe—attaching the leather upper to the sole—was done manually by skilled laborers, limiting mass production. Matzeliger’s machine mechanized this process, dramatically reducing the cost of shoes and making affordable footwear widely available.

- Precision Feeding: This specific invention is critical because high-speed industrial machinery requires positive, reliable feeding of components (tacks). The spiral separator solved the complex problem of converting tacks from a bulk, random state into a single-file, perfectly timed stream—a fundamental requirement for automated assembly.

Relation to Current Items

The spiral separation and positive-interval feeding concepts are foundational to automation engineering:

- Fastener Feeding Systems: The spiral screw is the direct mechanical precursor to modern vibratory bowl feeders and linear feeders used universally in manufacturing. These systems take bulk fasteners (screws, tacks, rivets) and use vibration or gravity to orient them and feed them one-by-one into robotic or automated assembly tools.

- Auger/Spiral Conveyors: The basic design of the screw is that of an auger or spiral conveyor , a design still heavily used to move bulk materials (grains, powders, plastics) precisely and controllably in processing plants and assembly lines.

- Positive Displacement: The mechanism achieves positive displacement of the tack—the screw physically grabs the tack, separates it, and moves it forward, ensuring the output matches the screw’s revolution rate. This concept is vital in all manufacturing processes requiring high-speed, guaranteed-single-piece part delivery.