Motor-Control System for Self-Serving Tables (Essex DeLoatch, No. 1,466,890)

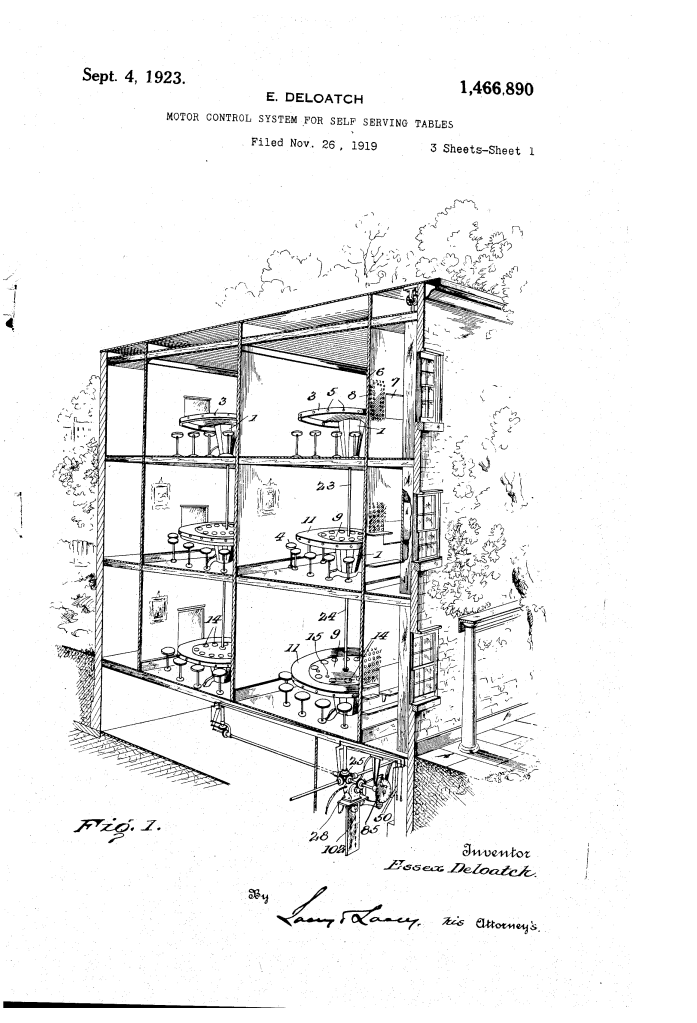

The patent by Essex DeLoatch of Philadelphia, Pennsylvania, describes a Motor-Control System for Self-Serving Tables (Patent No. 1,466,890, 1923). This invention is an automated dining system designed for high-efficiency food service in lunchrooms or restaurants. DeLoatch’s primary objective was to allow a large number of patrons to be served expeditiously from a central kitchen without the need for waiters, utilizing a rotating table system controlled by a remote operator.

Inventor Background: Essex DeLoatch

Essex DeLoatch was an African American inventor who envisioned the “restaurant of the future” during the post-WWI era of industrial automation. His 1919 application (granted in 1923) addressed the labor-intensive nature of food service. By treating the dining room like a mechanical assembly line, DeLoatch aimed to lower costs and improve hygiene. His background in electrical and mechanical systems is evident in the sophisticated use of “selector switches” and “solenoid brakes,” technologies that were cutting-edge for commercial applications at the time.

Key Mechanical & Electrical Systems

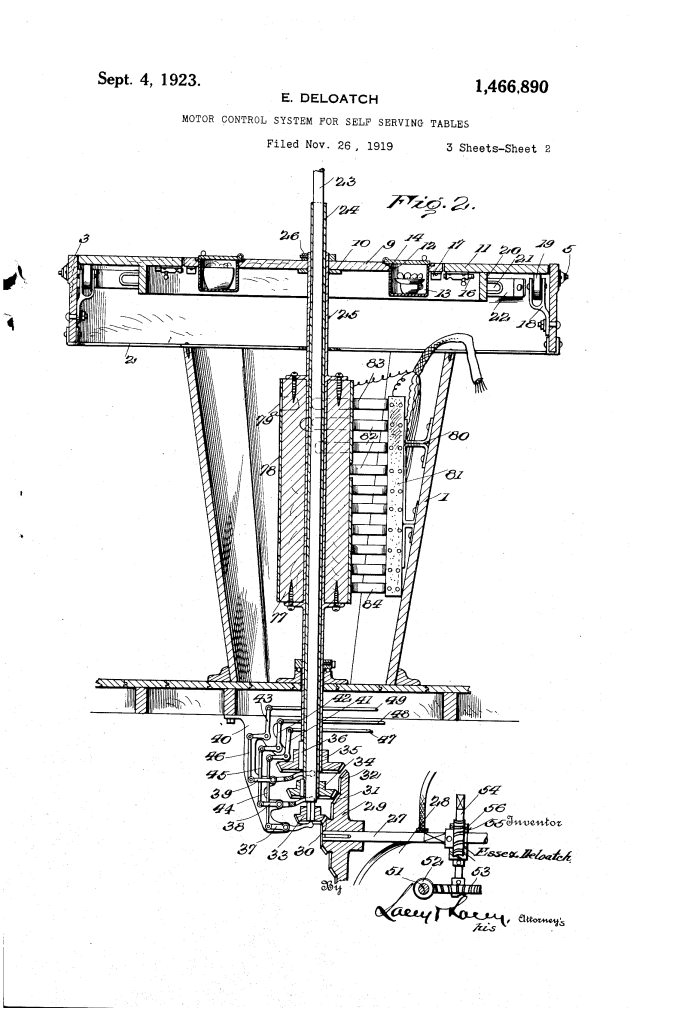

The system centers on a multi-sectional table top (9) mounted on a hollow pedestal (1) and driven by an electric motor (28).

1. The Multi-Sectional Table Top (10, 11, 13)

- Inner Rotating Section (10): This section contains an annular series of openings (12) housing receptacles (13) with hinged lids. These receptacles carry food orders, money, and messages between the guest and the kitchen.

- Outer Stationary Section (11): This is where guests eat. It is normally stationary but can be “locked” to the inner section using sliding bolts (16) so the attendant can rotate the whole top to collect dirty dishes.

- Serving Station (7): A window in a partition wall where the “attendant” (chef/server) interacts with the rotating receptacles as they pass by.

2. The Multi-Floor Drive System (23, 24, 25)

To serve multiple floors of a building, DeLoatch designed a nested sleeve-shaft system:

- Concentric Shafting: Three tables on three different floors are powered by three shafts nested within one another (like a telescope).

- Selective Gearing: A master gear (29) in the basement drives the shafts. An operator uses rocker arms (37, 38, 39) and pull cables to selectively engage or disengage the gears for a specific floor.

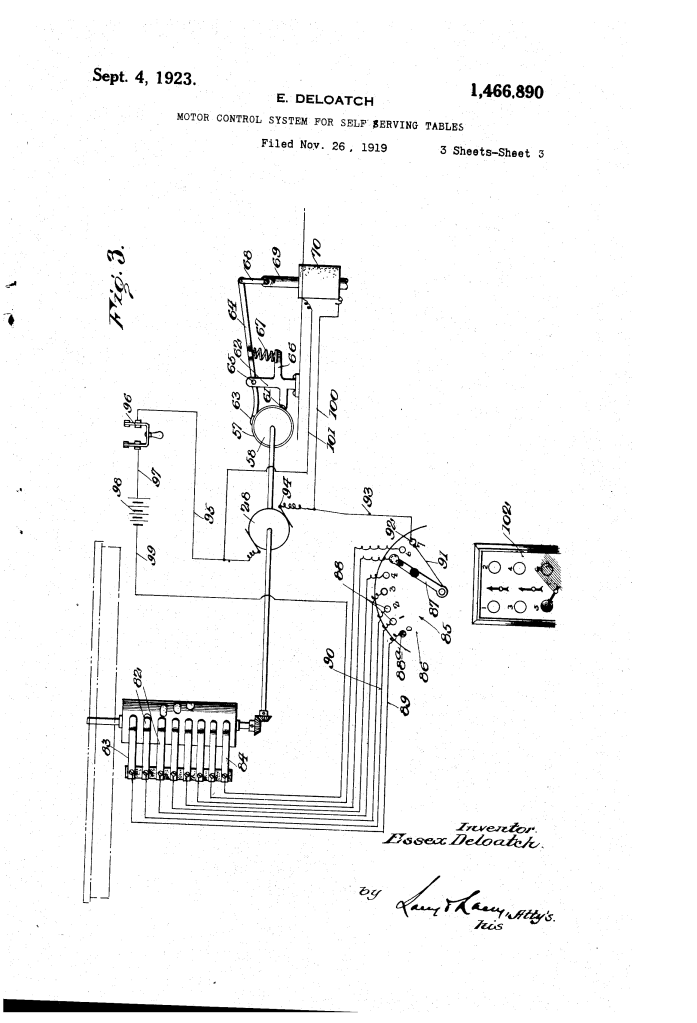

3. Automated Positioning Control (76, 85)

The “brain” of the table is a Contact Drum (76) located inside the pedestal.

- Commutator Logic: The drum is covered in a conductive sheathing (78) with “cut-away” insulation points (79) arranged in a stepped pattern.

- The Selector Switch (85): When the operator moves the switch lever (87) to a specific guest’s number, the motor runs until the corresponding contact finger (82) hits an insulated spot on the drum.

- Solenoid Brake (70): To ensure precision, a solenoid-controlled brake snaps shut the moment the circuit is broken, stopping the table exactly in front of the correct guest or the serving window.

Engineering Features and Operational Workflow

| Feature | Hazard/Problem Addressed | DeLoatch’s Engineering Solution |

| Worm Gear Drive (52-56) | Spilled food/liquids. | Reduces high-speed motor rotation to a slow, steady “creep” for the table sections. |

| Pockets (15) | Payment and Communication. | Dedicated slots for order slips and change, facilitating a “waiterless” transaction. |

| Annunciator Board (8) | Identifying guest needs. | Electrical push-buttons at each seat alert the kitchen exactly which station requires service. |

| Sleeve Shafting | Serving multiple floors. | Allows one motor in the basement to power tables on different levels independently. |

Significance to Food Service Engineering

Essex DeLoatch’s “Self-Serving Table” was a direct ancestor to several modern concepts in the hospitality industry.

- The “Automaton” Philosophy: His design anticipated the popularity of “Automats” and modern revolving sushi bars (Kura-style), where mechanical transport replaces human labor for delivery.

- Remote Logistics: The use of centralized motor control and Concentric Shafting reflects a sophisticated understanding of power distribution in vertical architecture.

- Precise Indexing: The contact drum/selector switch system is an early form of mechanical programming, allowing a non-technical operator to “program” the table to stop at specific coordinates.