Mechanism for Overcoming Dead-Centers (Willie H. Johnson, No. 612,345)

The patent by Willie H. Johnson of Navasota, Texas, describes a second-generation Mechanism for Overcoming Dead-Centers (Patent No. 612,345, 1898). This is an improvement on his earlier patent (No. 554,223), aiming for simplification, cheaper construction, and reduced friction and wear. The core is a dynamic system that uses alternating centers of oscillation to create the necessary lateral thrust to push the crank past the dead center points, integrating the timing for the steam valve itself.

Inventor Background: Willie H. Johnson

Willie H. Johnson was an inventor from Navasota, Texas, who dedicated his work to solving the persistent engineering challenge of the dead center in reciprocating motion engines. His inventions are characterized by their complexity and their attempt to provide a purely mechanical solution to a fundamental physics problem, often relying on intricate linkages, locking yokes, and cam systems.

Invention and Mechanism

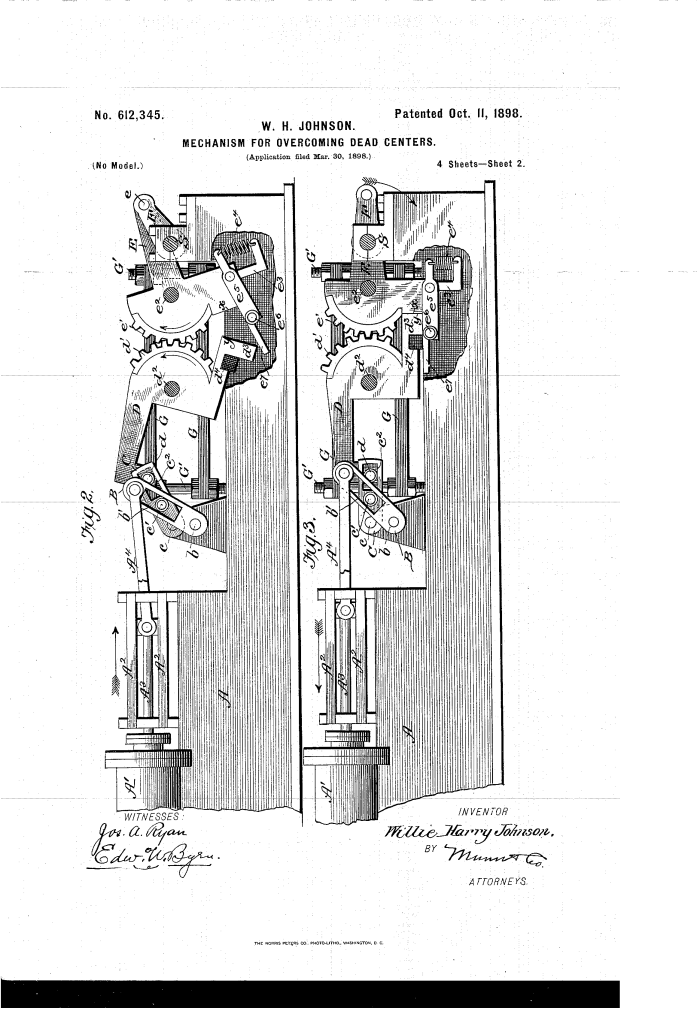

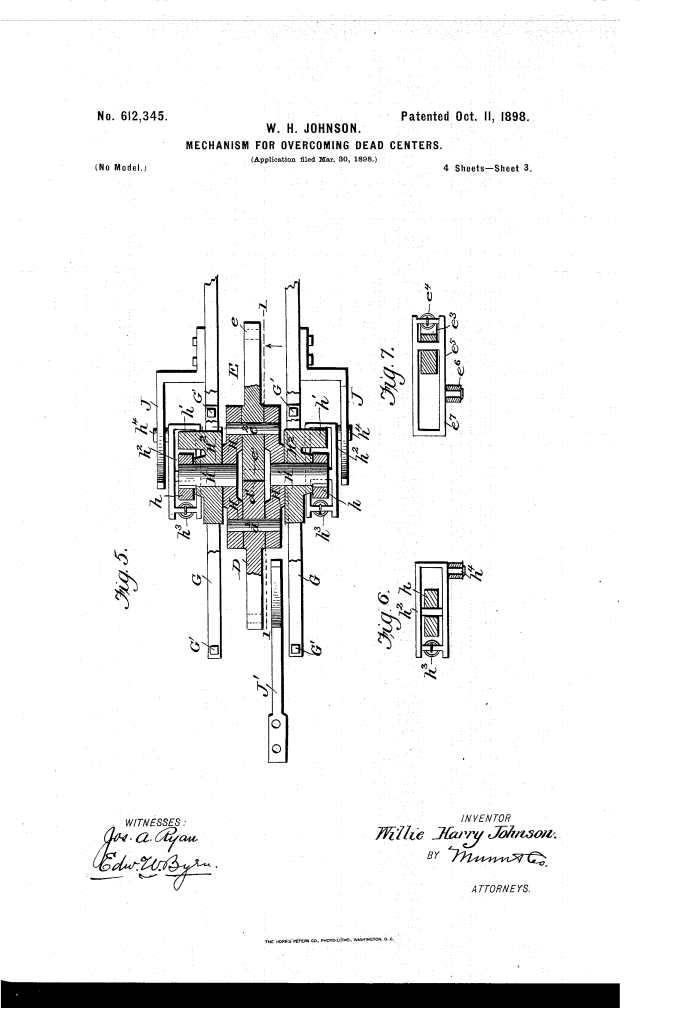

The mechanism uses a complex system of intermeshing segment gears and automatically operated locking yokes to create alternating centers of oscillation, integrated with a mechanically triggered valve gear.

1. Compound Linkage System

- Rocking Heads (D, E): The core components are two rocking heads, D and E, mounted on independent axes (

).

- Intermeshing Segment Gears (): The heads D and E are provided with toothed segment gears that intermesh, ensuring they rock synchronously in opposite directions.

- Sliding Journal Plates (): The axes of the heads D and E are carried by plates (H) which slide within guides (G).

2. Alternating Centers of Oscillation (Dead-Center Elimination)

The system alternates between two modes, controlled by automatically unlocking/locking devices hitting a stationary inclined bar (J).

- Mode 1: Double Center (Torsional Thrust): The heads D and E rock about their individual centers (

), acting as two independent levers. This happens when the crank is near the first dead center. The piston’s force causes the segments to rock, creating an angular force (thrust) to push the crank past the center.

- Actuation: This mode is maintained when the locking yoke () is engaged, preventing the journal plates (H) from pivoting.

- Mode 2: Single Center (Direct Thrust): The two heads D and E are rigidly locked together by a locking yoke () that snaps over the arm (

). The heads now act as a single, rigid lever rocking about the intermediate trunnion-fulcrum (H’). This is necessary for the reverse thrust at the other dead center.

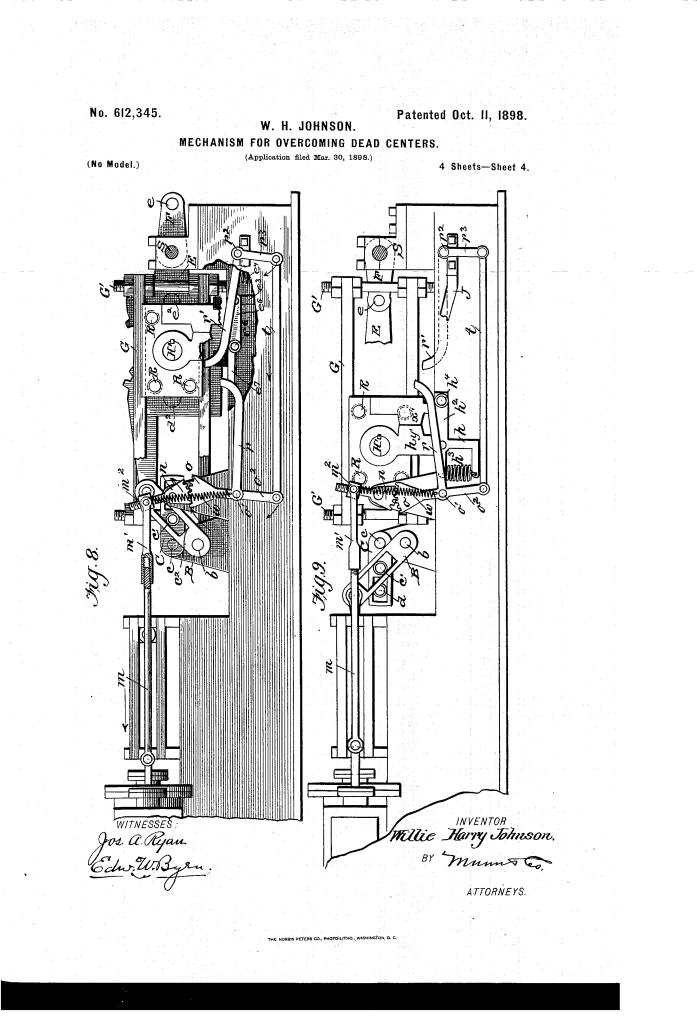

3. Integrated Valve Gear (Key Improvement)

- Tappet Arms (): The valve-rod operating linkage includes two tappet arms (

), one for each dead center.

- Synchronization: The locking yokes ( and ) are positioned so that as they snap into their locking position (by action of their springs

and

) at the moment a dead center is reached, they simultaneously strike and lift the corresponding tappet arm (

or

).

- Function: This immediately shifts the slide-valve to admit steam to the cylinder, ensuring work is done exactly at the dead-center point, preventing the engine from stalling.

Concepts Influenced by This Invention

Johnson’s complex mechanism is a precursor to modern electronic and mechanical control systems that require dynamic, timed intervention based on the position of a rotating shaft.

- Dynamic Kinematic Switching: The core principle of a linkage that automatically and sequentially switches its point of mechanical action (fulcrum) and its structural rigidity (locked/unlocked) based on the position of the input arm influenced the design of complex intermittent motion drives, indexing mechanisms, and gear selector systems that must change their operating mode mid-cycle.

- Integrated Mechanical and Process Control: The direct, mechanical coupling of the structural locking mechanism (yokes) to the process valve actuation (tappet arms) influenced the philosophy of integrating machine safety and control. This concept is used today in industrial machinery where a mechanical state change (e.g., a limit switch hit) triggers a crucial process function (e.g., opening a valve, initiating a new cycle).

- Segmented Gear Timing: The use of toothed segment gears for precise, uniform transfer of angular motion and the integration of mechanical stop faces () on the segments to control the alignment of the system centers influenced the design of precise angular indexing and mechanical timing devices.

- Pre-Set Friction and Wear Reduction: The incorporation of friction-rollers (R) on sliding surfaces and locking pins demonstrates a focus on minimizing friction in the complex system, a necessary step for any mechanism designed for high-speed industrial operation.