Mechanism for Overcoming Dead-Centers (Willie Harry Johnson, No. 554,223)

The patent by Willie Harry Johnson of Navasota, Texas, describes a Mechanism for Overcoming Dead-Centers in machines where a shaft is driven by a crank, such as a steam engine. The invention aims to prevent the crank from getting stuck at the points where the piston rod is aligned with the crank arm (the dead centers).

Invention and Mechanism

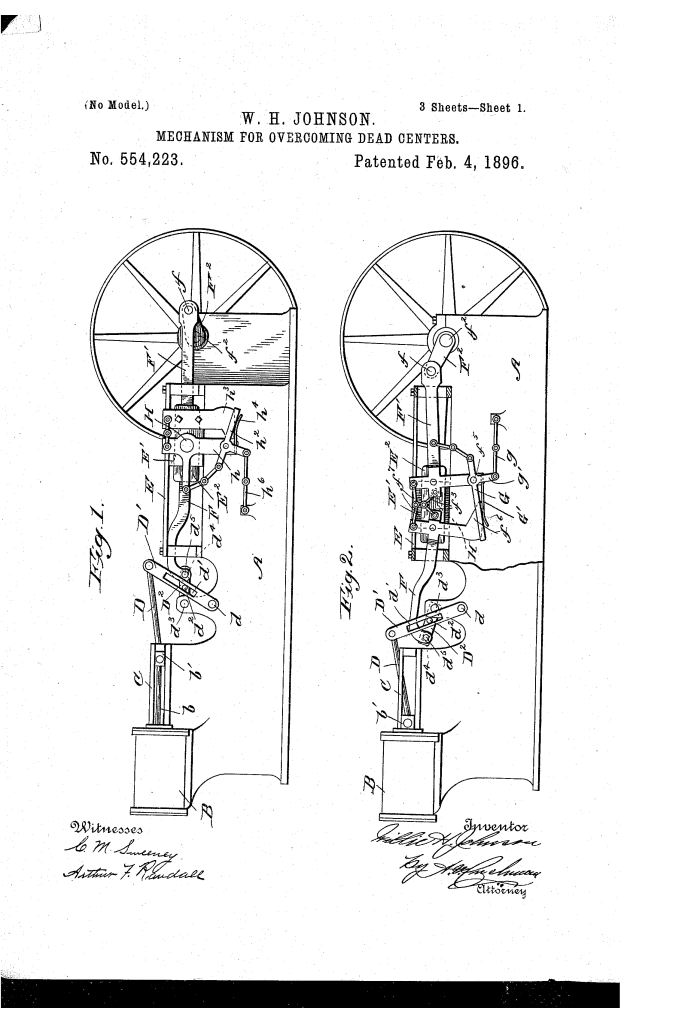

The invention utilizes a unique two-part or compound crank-rod whose members are automatically locked or unlocked at precise points in the stroke to create a lateral thrust, pushing the crank past the dead center.

1. Compound Crank-Rod Structure

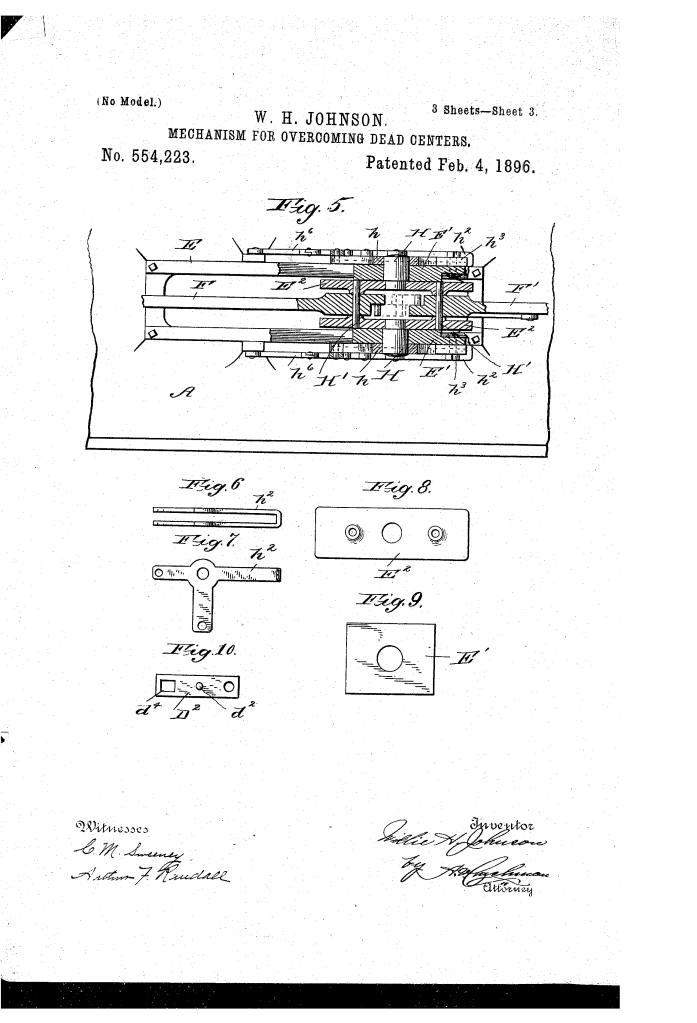

- Members (F, ): The crank-rod is formed by two cross-shaped members (

,

).

- Member

(Output): The long arm engages the crank-pin (

) of the driven shaft (

).

- Member F (Input): The long arm connects to a slotted swinging arm (

), which is driven by the piston rod (

).

- Member

- Toggle Linkage: The inner ends of the two members (

) are connected by links (), forming a toggle connection.

- Mounting: The two members are pivotally mounted on two pivots (H) housed within sliding blocks (

), which move along a guideway (E) on the engine base (A).

2. Automatic Locking and Thrust (To Overcome First Dead Center)

- Locking Strap (G): A strap pivoted to member

that engages a foot (

) on the transverse arm of member

, locking the two members together to act as a single, rigid rod.

- Operation (Thrust): When the crank approaches the first dead center, the piston’s motion drives the swinging arm (

), which lifts the input end (F) of the rigid crank-rod. Since the members are locked, they pivot on their main pivots (H), forcing the output end (

) connected to the crank-pin directly downward past the dead center line.

- Automatic Unlocking: When the crank-pin reaches a position diametrically opposite the first dead center, a double link () secured to the machine frame pulls the strap (G) off the foot (

), unlocking the two members (). A spring (

) is used to automatically lock the members when they return to the locking position.

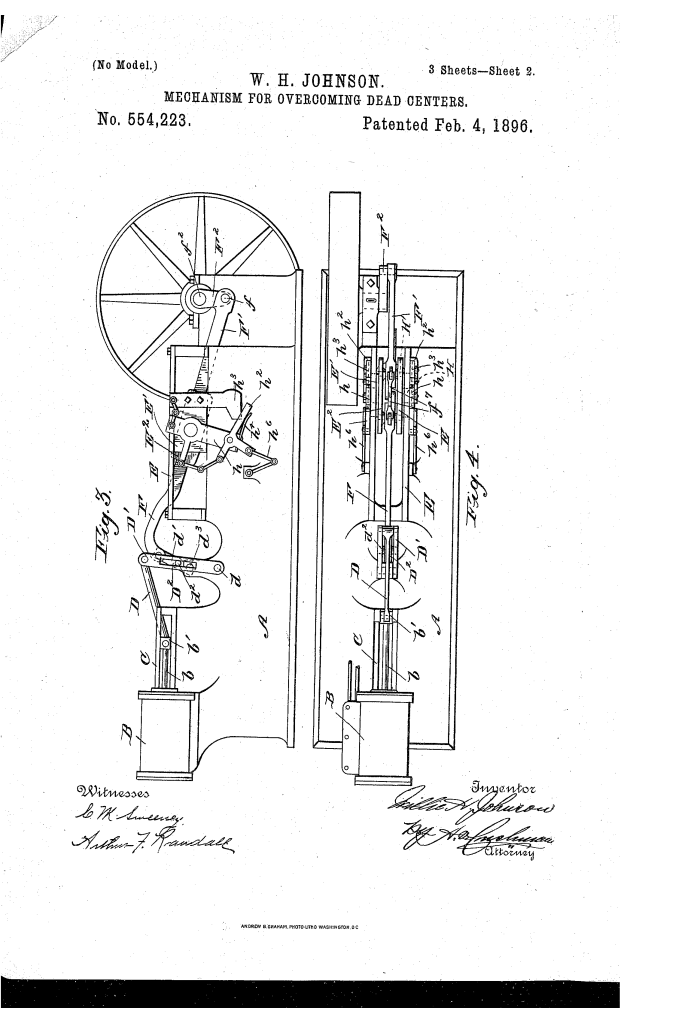

3. Independent Movement and Thrust (To Overcome Second Dead Center)

- Mounting Lock (Straps ): As the crank reaches the second dead center, the sliding plates (

) are locked against pivotal movement on their pivots (H) by separate straps (

) that engage arms (

) on the sliding blocks.

- Operation (Thrust): The two members (

) are now unlocked and turn on their individual pivots (H). The piston drives the input member F upward, causing its short arm to swing downward. Through the toggle link connection (), this motion tilts the output member (), giving the crank-pin an upward thrust to carry it past the second dead center point.

- Release: Just before reaching the first dead center again, the mounting lock straps (

) are automatically disengaged, and the main strap (G) automatically locks the members (

) together again.

Historical Significance and the Inventor

Willie Harry Johnson’s 1896 patent is a complex attempt to solve one of the oldest and most fundamental problems in mechanical engineering: the dead center of the crank mechanism.

- The Dead Center Problem: In simple crank-and-piston systems (like early steam engines), there are two points in every rotation where the crank is aligned with the piston rod. At these “dead centers,” the piston’s force is applied directly along the crank arm, providing zero rotational torque. The machine stops unless external momentum (flywheel) carries it through.

- Mechanical Solution: Johnson’s invention sought to provide a purely mechanical solution—a “dead-center eliminator”—by actively creating a torque-generating lateral thrust at the moment the crank should stall. While flywheels are the standard solution, Johnson’s complex system is notable for its ingenious use of locking, unlocking, and toggle linkages to perform this function dynamically.

- The Inventor (Willie Harry Johnson): Johnson, residing in Navasota, Texas, contributed a highly ambitious and complex design to the field of mechanical motive power.

Core Concepts Utilized Today

While highly specialized and often replaced by flywheels or electronics, Johnson’s mechanism utilizes advanced principles of kinematics and mechanical locking.

- Toggle Linkages for Force Multiplication: The toggle link () connection is a classic mechanical component used to convert small linear movement into large linear or angular force. Today, toggle linkages are widely used in everything from locking clamps and vises to rock-crushing machinery and injection molding presses where a massive mechanical advantage is required.

- Automated Clutches and Locking Mechanisms: The use of spring-pressed straps (G, ) and links () for automatic, timed locking and unlocking is a sophisticated mechanical control system. This principle is utilized in various modern automated clutches, sequential gearboxes, and safety locks that must engage or disengage based on the position or cycle of the main drive shaft.

- Kinematic Conversion for Thrust: The core idea of using complex linkages to generate a force perpendicular to the primary line of action is a principle of advanced robotics and parallel kinematics. This is used in multi-axis machinery where a linear input (like the piston) must generate non-linear or multi-directional output forces for manipulation or movement.