Mechanism for Distributing Tacks, Nails, &c. (Jan Ernst Matzeliger, No. 415,726)

The patent by Jan Ernst Matzeliger of Lynn, Massachusetts, describes a Mechanism for Distributing Tacks, Nails, and other Small Suspendable Articles (Patent No. 415,726, 1889). The invention’s object is to provide a mechanism that receives small articles (like tacks) in bulk, shifts them reliably, and feeds them to a chute, while employing a system to prevent and clear jams or clogs.

Inventor Background: Jan Ernst Matzeliger

Jan Ernst Matzeliger (1852–1889) was a pivotal African-American inventor whose work revolutionized the shoemaking industry. He is most famous for his lasting machine, which this tack-distributing mechanism was designed to feed. His inventions drastically reduced the cost of shoe manufacturing, making affordable footwear widely available.

Invention and Mechanism

The machine uses a two-part, vibrating chute and a unique self-clearing mechanism where the bulk of the tacks is utilized to eliminate clogs.

1. Chute and Suspension

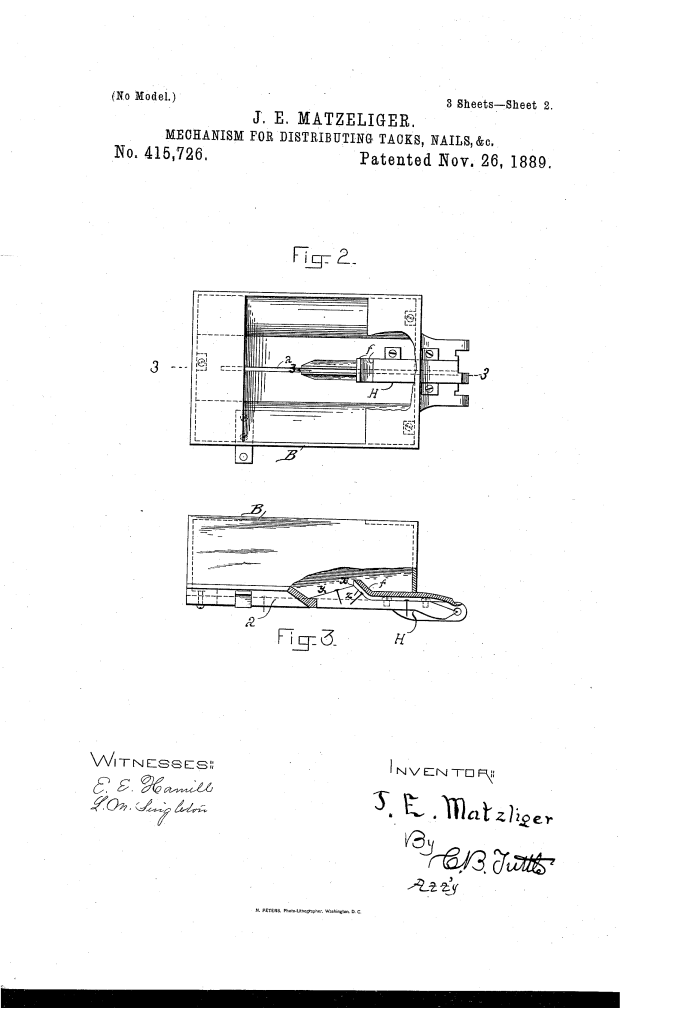

- Chute ($a$): A continuous slot or channel (raceway) along which the tacks travel suspended by their heads (bodies projecting downward). The chute is smoothly polished and inclined so the tacks naturally gravitate downward.

- Bridge or Cover ($f$): A cover that overhangs the chute below its upper end.

- Function: This bridge acts as a stop device, preventing improperly suspended tacks (those not seated well in the raceway) from entering the main feed, ensuring high-quality input to the separator.

2. Agitation and Feeding (The Shifter)

- Two-Part Chute: The chute consists of a fixed lower section and an upper movable section (B’) integrated with the hopper (B).

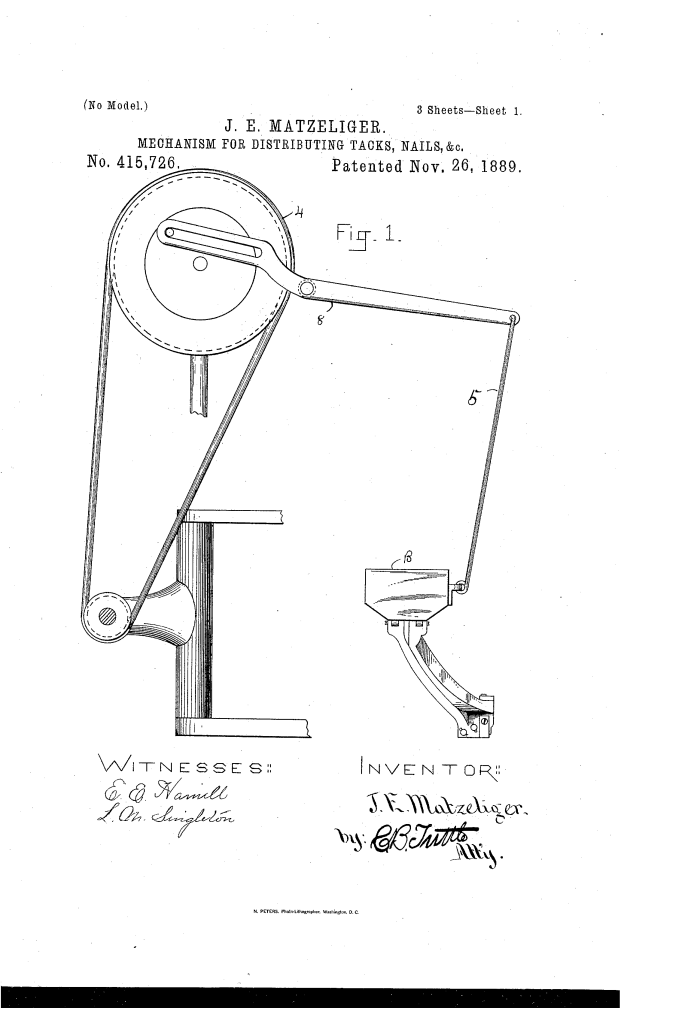

- Agitator: A crank-wheel (4) and pitman (5) are used to transmit power, causing the entire hopper (B) to tilt or move about a pivot.

- Function: The tilting moves the bulk of tacks within the hopper, forcing them to crowd into the exposed raceway portion, ensuring the chute remains filled.

3. Self-Clearing Mechanism (Crucial Innovation)

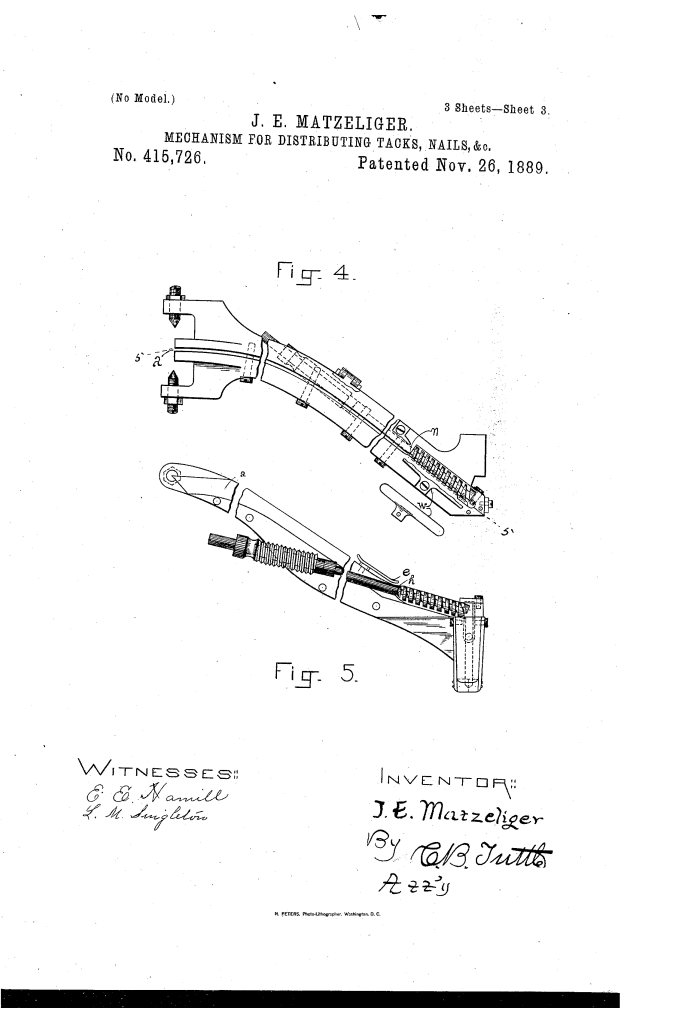

- The Problem: Despite the bridge ($f$), tacks can get cramped or stuck in the raceway before reaching the bridge.

- The Solution (The Drag/Clearer): The tilting motion of the hopper causes the body of loose tacks (the bulk) to shift from one end of the hopper chamber to the other.

- Function: In transit, the bulk of tacks slides along the bottom of the hopper and engages the obstructing tack in the raceway, effectively releasing and dragging it along with the bulk. This utilizes the loose tacks as a kind of drag or clearer to keep the raceway free of jams in front of the bridge stop ($f$).

Concepts Influenced by This Invention

Matzeliger’s design influenced subsequent industrial feeders by pioneering self-clearing mechanisms that rely on the mass of the bulk material itself.

- Mass-Flow Self-Cleaning: The most significant influence is the concept of leveraging the bulk material (the body of loose tacks) as an active clearing agent (a “drag”) to eliminate clogs. This influenced the design of modern vibratory feeders, hoppers, and grain processing equipment that use controlled agitation or flow patterns to prevent jams and maintain a continuous feed rate.

- Integrated Screening and Culling: The function of the bridge ($f$) to act as a geometric screen or quality control stop (allowing only perfectly seated tacks to pass) influenced the design of automated feeders that pre-qualify components before they enter the final processing stage.

- Vibratory/Shaking Agitation: The use of crank-driven linkage to agitate the hopper to shift the bulk material is a foundational principle of modern vibratory hopper feeders used widely in manufacturing to fluidize and feed parts.

- Dual-Action Motion: The ability of the device to use a single motion (the hopper tilt) to perform two jobs (1) feed the chute and (2) clear clogs influenced the development of multi-functional actuators in automation.