Matrix-Drying Apparatus (Benjamin F. Jackson, No. 603,879)

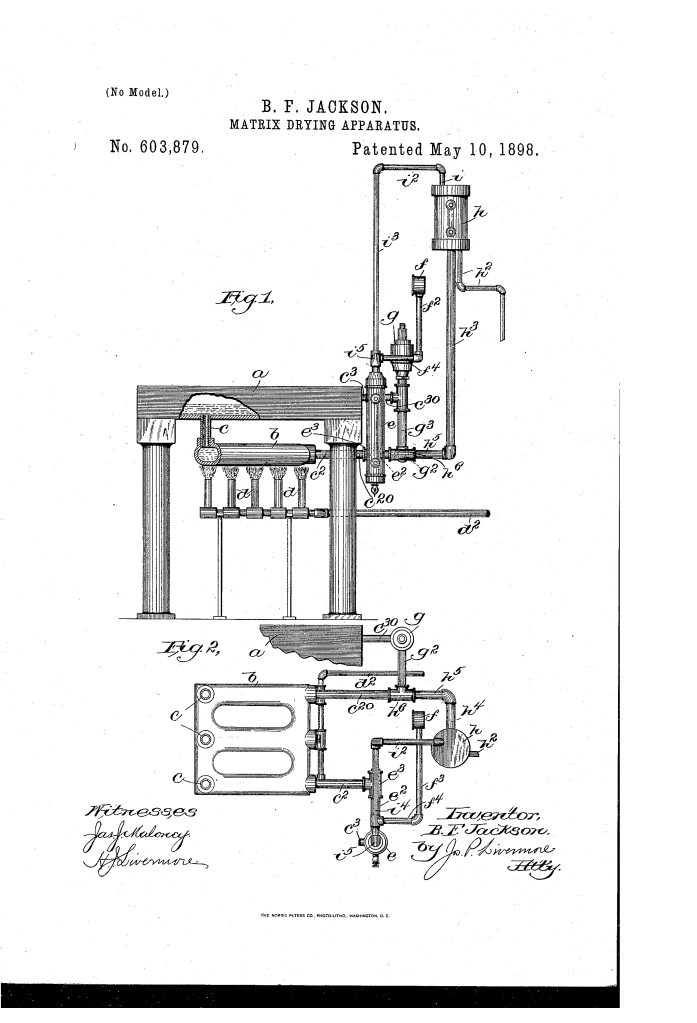

The patent by Benjamin F. Jackson of Cambridge, Massachusetts, describes a Matrix-Drying Apparatus (Patent No. 603,879, 1898) used in printing offices for drying wet pulp-matrices before casting stereotype-plates. The invention’s object is to provide a complete, self-contained drying apparatus capable of quickly generating an intense and evenly distributed heat without scorching the pulp.

Inventor Background: Benjamin F. Jackson

Benjamin F. Jackson was an inventor specializing in thermal and industrial equipment, previously patenting a high-efficiency gas-fired water heater. This patent demonstrates his continued focus on applying principles of heat transfer and fluid dynamics to industrial processes, specifically targeting the efficiency and speed requirements of the newspaper and printing industries.

Invention and Mechanism

The apparatus is a self-contained steam-based heating system that uses a small, focused generator to quickly create steam for a large, flat drying table.

1. Steam Generation and Table

- Drying Table (a): A steam-tight chamber with a large, flat top surface to receive the matrix.

- Generator (b) (Key Innovation): A reservoir or steam-generator of substantially less capacity than that of the table, mounted directly below the table. It is shown as a single casting with longitudinal channels.

- Function: The small size of the generator concentrates the heat, allowing the water therein to be rapidly heated and converted into steam. This steam then rises through connecting pipes (c) to fill the large, flat table chamber ($a$).

- Heat Transfer: The small, high-intensity steam source quickly and evenly heats the large top surface of the table, making the drying process fast and uniform (saving four or five minutes per operation).

2. Water Supply and Pressure Equalization

- Supply-Tank (h): A water-supply tank connected to an external water source.

- Pressure Equalizing Duct (i): A pipe connecting the top of the supply-tank (h) with the steam-space in the top of the table (a).

- Function: By equalizing the pressure between the tank and the steam-chamber, the pressure in the tank is made equal to that in the table. This allows the water to flow by gravity from the supply-tank (h) into the generator ($b$) when desired.

- Gauges and Safety: The system is equipped with a water-gage ($e$), a pressure-gage ($f$), and a safety-valve ($g$) connected to the piping system.

3. Burners

- Burners ($d$): A series of burners arranged directly below the generator ($b$).

- Function: The heat is concentrated on the small generator, ensuring rapid steam production.

Concepts Influenced by This Invention

Jackson’s matrix dryer influenced subsequent industrial thermal equipment by pioneering the use of a high-intensity, small-volume boiler to rapidly charge a large low-pressure heating surface.

- Dynamic Steam Generation (On-Demand Heating): The core principle of using a small, high-focused generator (b) to achieve rapid steam-up times for a larger process target (table $a$) influenced the design of modern point-of-use steam systems and industrial equipment that requires quick thermal cycling.

- Pressure-Equalized Gravity Feed: The system for equalizing the pressure between the water-supply tank and the main vessel (via pipe $i$) to facilitate gravity-feed influenced the design of industrial fluid reservoirs and feeder tanks, ensuring reliable, passive replenishment of liquid into a pressurized system.

- Steam Press Heating: The apparatus is a direct precursor to modern steam-heated platens, presses, and industrial drying tables used in manufacturing, where large, flat surfaces must maintain extremely uniform and high temperatures.

- Self-Contained Utility: The design goal of creating a “complete, self-contained apparatus” that integrates the heater, boiler, feed, and gauges influenced the trend toward manufacturing integrated, standalone machinery packages for specific industrial tasks.