The patent by Clatonia Joaquin Dorticus of Newton, New Jersey, describes a Machine for Embossing Photographs (Patent No. 537,442, 1895). It is a versatile press designed for either mounting photographic prints (adhering them to a card or backing) or embossing photographs using interchangeable dies. The primary object is to ensure an equal and uniform pressure over the entire surface of the photograph during either process.

Invention and Mechanism

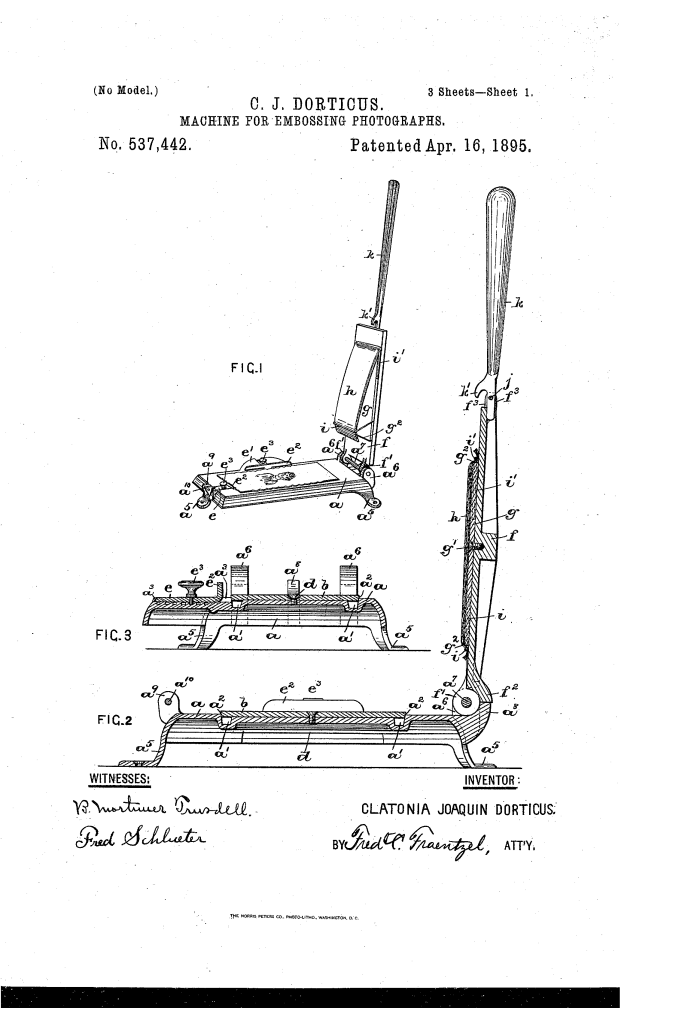

The machine is a hinged press with interchangeable plates/dies, featuring a self-leveling mechanism to guarantee even pressure.

1. Structure and Clamping

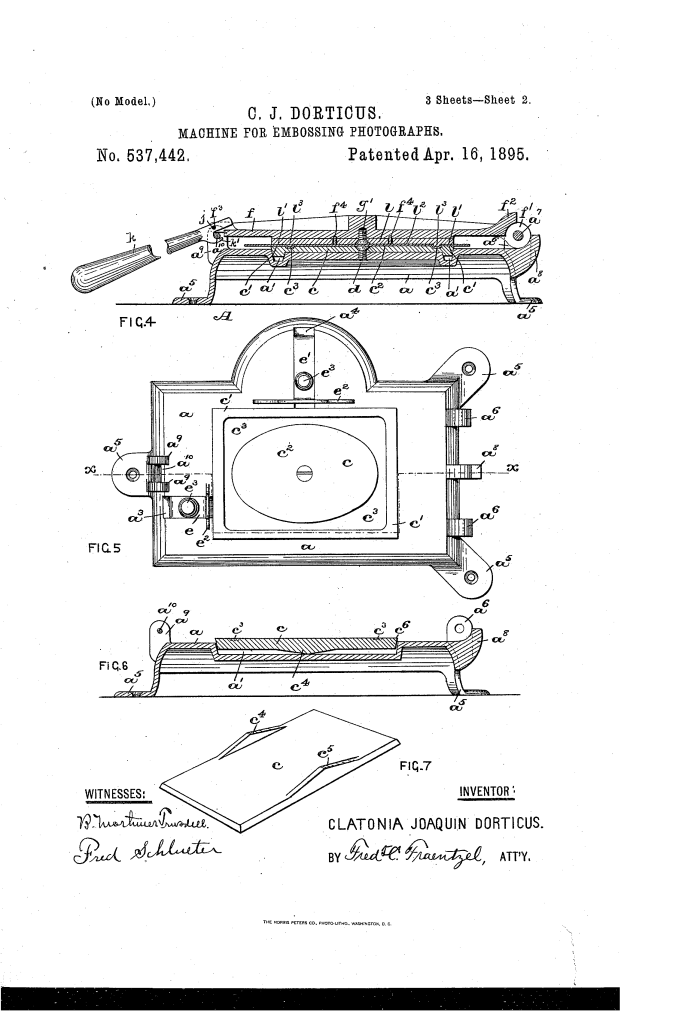

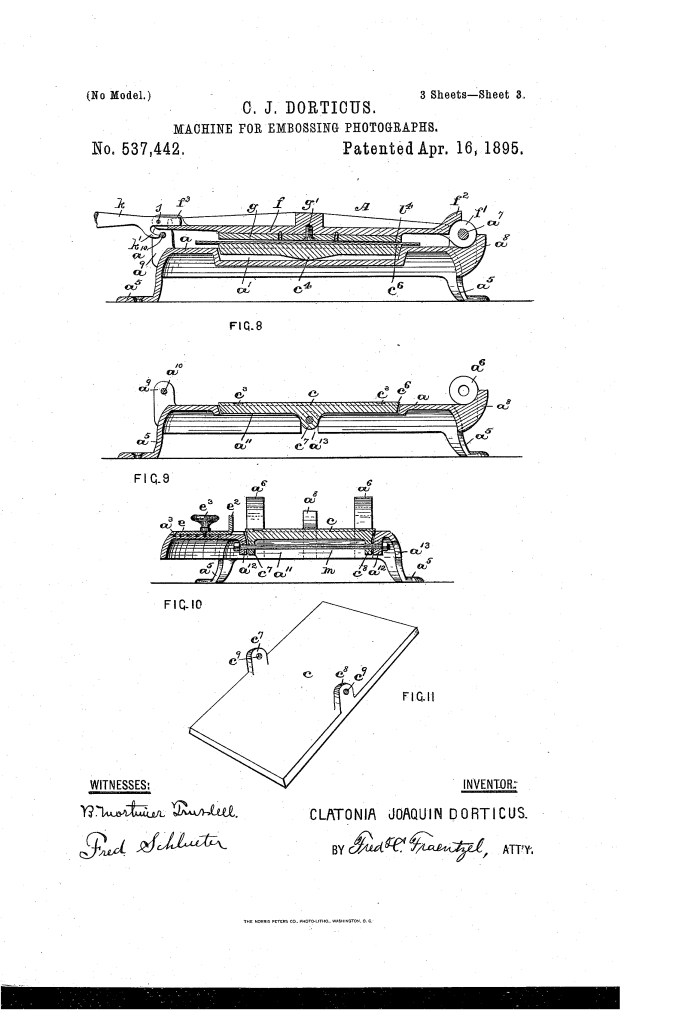

- Base (a) and Bed Plate: Forms the base of the machine and includes a recessed portion (a′) to seat the working plate or lower die. It may be secured to a table.

- Hinged Pressure Bar/Plate (f): A heavy plate hinged to the base via lugs (a3,f′). A stop (a4) limits its open swing.

- Clamping Mechanism: A hand lever (k) is pivoted to the pressure bar (f). The lever has a grasping jaw (k′) that engages under a holding pin (j) on the bed plate (a).

- Function: Applying slight pressure to the lever (k) clamps the pressure bar (f) securely down onto the bed plate, distributing an even pressure over the entire surface.

2. Mounting Function

- Mounting Plate (b): This plate is secured in the recessed portion (a′) of the bed plate.

- Pressure Material (h): The underside of the pressure bar (f) is covered with a soft and flexible material (h), such as felt, firmly held in place by wire yokes (i,i′).

- Function: When mounting a gummed print onto a card, the soft material (h) brings an evenly distributed pressure over the entire print surface, preventing creases caused by trapped air and simultaneously absorbing water from the print.

- Guide Plates: Adjustable guide plates (e,e′) are set in slots (a5,a6) on the bed plate to allow the operator to quickly center any size card board.

3. Embossing Function

- Interchangeable Dies: The mounting plate (b) is removed, and a lower die (o) is secured to the bed plate. An upper die (l) is secured to the pressure bar (f).

- Die Configuration: The lower die (o) has raised edges (o′) and a raised center (o2), forming a recess. The upper die (l) has a corresponding lowered edge (l′ and l2) and a raised center (l3).

- Function: When the pressure bar is clamped down, the corresponding contours of the male (upper) and female (lower) dies press the photograph, creating a neatly embossed picture.

4. Self-Leveling (Oscillatory Die)

- Oscillatory Die Feature: The lower die (o) may be provided with central bearings (rockers c3,c4), allowing the die to oscillate slightly in the recessed portion (a′).

- Function: As the pressure bar is brought down, the edge of the upper die strikes the lower die, causing it to oscillate. This movement ensures the two die faces are in perfect contact and that the pressure is applied uniformly over the entire surface of the card before the final clamping pressure is exerted.

Historical Significance and the Inventor

Clatonia Joaquin Dorticus’s 1895 patent is a key development in the commercial finishing of photography, a rapidly expanding industry in the late 19th century.

- Photography as an Industry: As photography moved from a novelty to a ubiquitous service (e.g., carte de visite and cabinet cards), efficient, high-quality finishing methods became essential. Mounting and embossing (a decorative finish that added value) were typically slow, skill-intensive tasks.

- The Inventor (Clatonia Joaquin Dorticus): Dorticus, an African-American inventor, was highly engaged in the photography industry, holding several patents related to developing and finishing. His machine mechanized two crucial finishing steps—mounting and embossing—into a single, simple, high-precision press. The emphasis on uniform pressure (via the self-leveling feature) was a direct technical solution to ensure professional, crease-free results at an industrial scale.

Relation to Current Items

Dorticus’s press utilizes mechanical and functional principles foundational to modern printing and assembly:

- Clamshell Presses: The hinged, lever-actuated clamping action is the basic design of modern clamshell heat presses used for applying vinyl, sublimation, and photographic transfers, where quick access and uniform pressure are vital.

- Uniform Pressure Systems: The concept of an oscillatory (self-leveling) lower plate is found in modern industrial presses and jigs where absolute parallelism is critical. These systems use floating bases or gimbal mounts to ensure the faces of the press make perfect, full-surface contact, regardless of minor variations in the workpiece thickness or frame alignment.

- Interchangeable Tooling: The ability to quickly swap the mounting plate for the embossing die demonstrates the principle of modular tooling, which is central to modern flexible manufacturing, allowing a single machine frame to perform multiple distinct operations.