Machine for Cleaning Seed-Cotton (Peter Walker, No. 577,153)

The patent by Peter Walker of Friars Point, Mississippi, describes a Machine for Cleaning Seed-Cotton (Patent No. 577,153, 1897). The invention’s object is to provide a comprehensive system for removing foreign matter, dust, and trash from seed-cotton and automatically delivering the cleaned cotton to the gins using a combination of suction and mechanical beating.

Inventor Background: Peter Walker

Peter Walker was an African-American inventor residing in Friars Point, Mississippi, a region central to cotton agriculture. His invention, patented in 1897, addressed a critical bottleneck in the cotton processing industry. Clean cotton leads to higher grades and profits, and his focus on an integrated, automated cleaning system was a major step toward modernizing the post-harvest stage of cotton production.

Invention and Mechanism

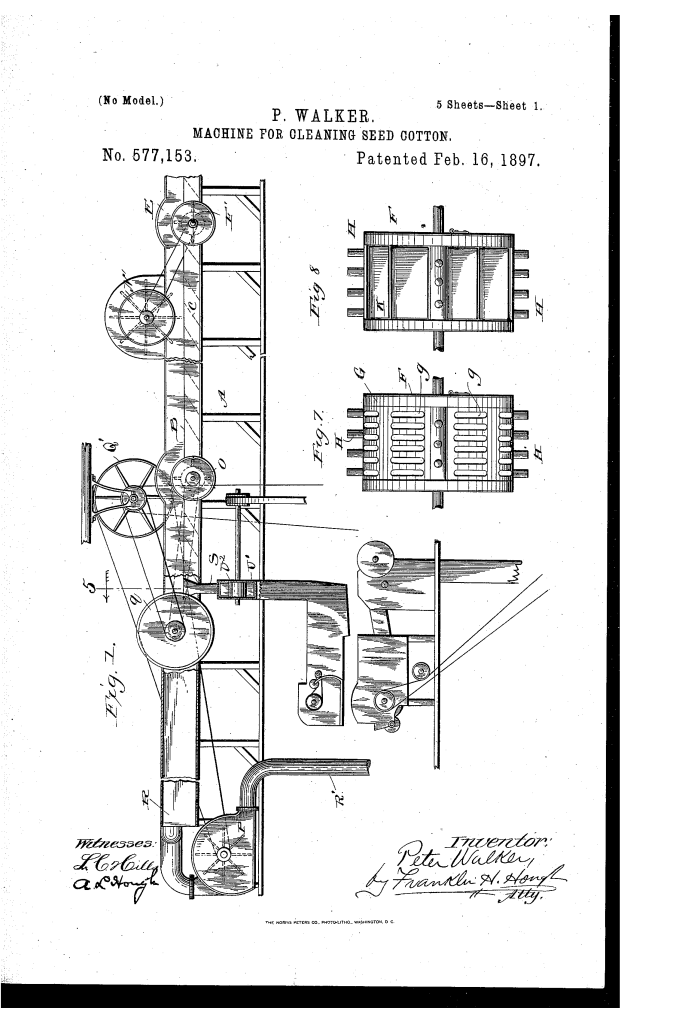

The machine is a multi-stage, sequential cleaning system that uses suction, beating, and centrifugal force for separation.

1. Pre-Cleaning and Trash Separation

- Trough (A) with Wire Series (B): The cotton is fed into a trough containing a series of horizontal wires (B) located slightly below the center.

- Function: The wires are spaced to allow foreign substances (trash) to pass between them but prevent the seed-cotton from falling through or clogging.

- Trash Compartments: The space beneath the wires is divided into compartments by inclined partitions (C), each with hinged doors (D) on the bottom for easy trash removal.

- Benefit: This initial stage allows water and heavy trash to drop out, partially drying and separating the cotton.

- Pocket (C2): A special pocket near the beater-wheel is designed to catch heavy foreign matter like nails before it hits the beater.

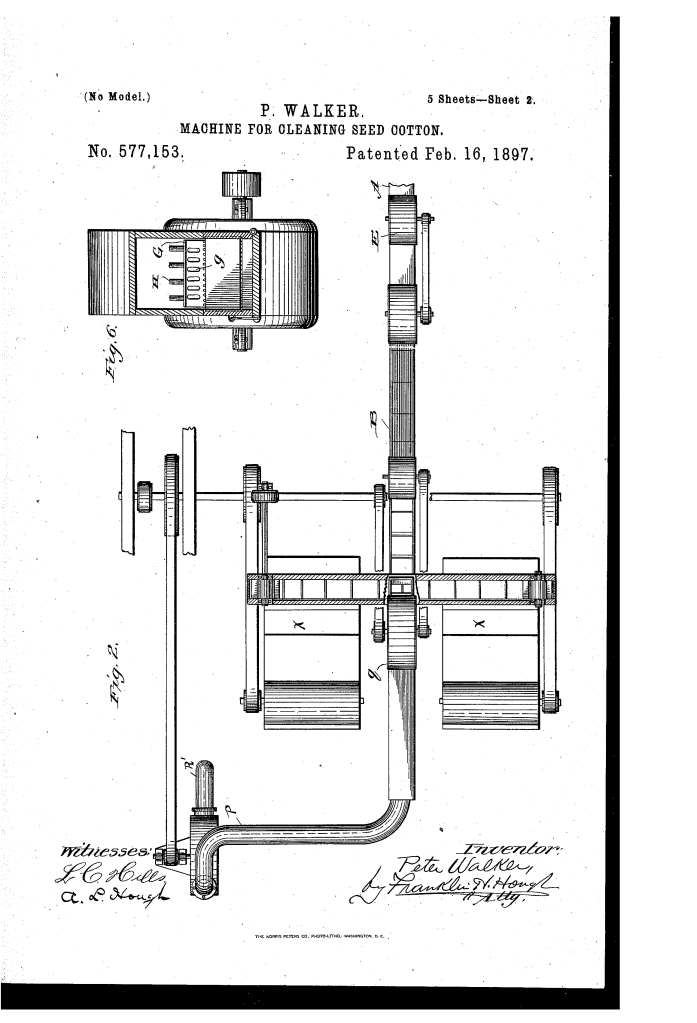

2. Beating and Centrifugal Cleaning (The Internal Vane Trap)

- Beater-Drum (F): A hollow drum with perforated ends (f) and rows of beater-arms (H) about its circumference. It rotates rapidly, opposite to the incoming cotton’s direction.

- Centrifugal Retainers (K): Rigid, curved wings or retainers are secured to the inner circumference of the drum, slightly overlapping one another, leaving small spaces.

- Function: Trash is beaten into the drum through the external apertures. Once inside, the centrifugal force of the fast-revolving drum throws the trash against the broad sides of the retainers (K), preventing it from being thrown back out through the small spaces through which it entered. This effectively traps the trash inside the drum until manual removal.

- Drive: The beater-drum (F) is driven by a belt from an air-wheel (N).

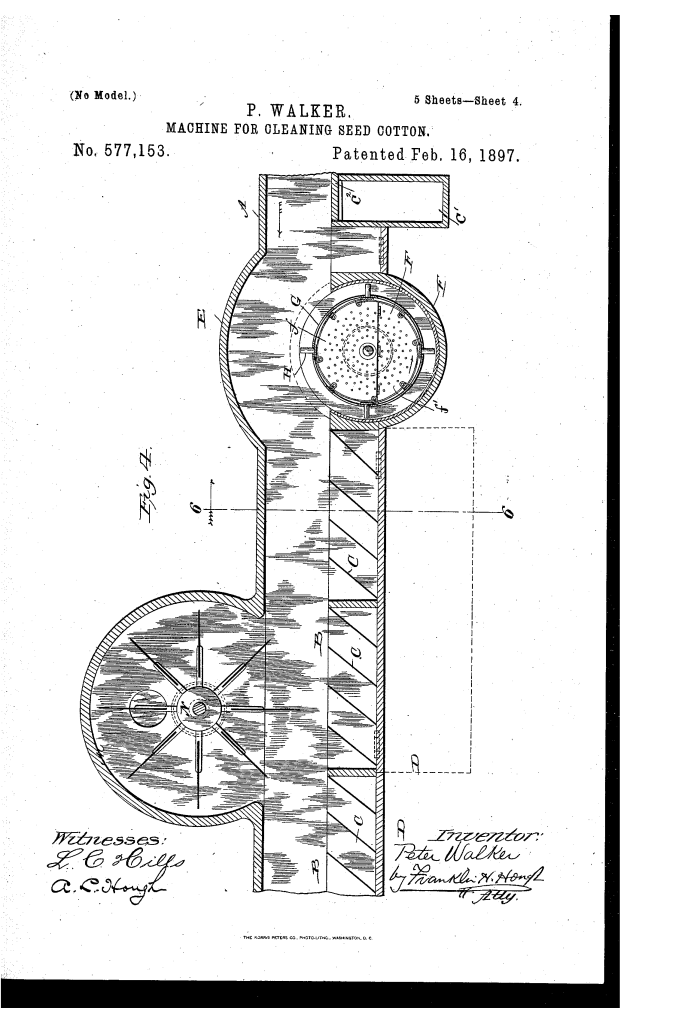

3. Suction, Screening, and Dust Removal

- Fan-Wheel (P) and Suction: A fan-wheel provides a powerful suction via a duct (R) to draw the seed-cotton up through the trough.

- Screen-Wheel (Q): A rapidly revolving wheel with a perforated circumference is journaled in the trough.

- Function: The cotton is drawn against the screen-wheel’s surface. The air and fine dust pass through the screen-wheel and out into the atmosphere, while the cotton falls away, freed of fine dust.

4. Clean Delivery to Gin

- Conveyer-Box (U) and Wings: The cleaned seed-cotton falls onto an endless belt conveyer with wings (U′) that snugly fit the upper and lower walls of the box.

- Function: This snug fit cuts off the supply of air coming from the gins. By preventing air from moving backward, a partial vacuum is formed in the conveyer-box, allowing the cotton (aided by gravity) to fall readily onto the carrier for discharge onto the gin-tables (X).

Concepts Influenced by This Invention

Walker’s machine influenced subsequent industrial cleaning and conveying systems by pioneering integrated, multi-stage, air-assisted cleaning processes.

- Centrifugal Debris Traps (Beater-Drums): The most direct influence is the design of a beater or drum with internal centrifugal retainers (K) to trap and segregate impurities. This principle is used in modern industrial hammer mills, cotton cleaners (lint cleaners), and dust collectors , where centrifugal force is used to separate heavy particles from lighter fibers.

- Airlift and Suction Conveyance: The use of suction (Fan P) to convey the raw material (cotton) through the cleaning process is the foundation for modern pneumatic conveying systems

in agriculture and manufacturing, which move bulk materials efficiently using air streams.

- Wire/Grizzly Screening: The use of horizontal wires (B) and inclined partitions to perform initial separation of large, heavy foreign matter is the basis for modern grizzly feeders and vibratory screens used in mining, recycling, and agricultural processing to remove oversized debris.

- Differential Air Pressure Conveying: The design using snugly-fitting wings (U′) in the conveyer-box to create a partial vacuum influenced the design of modern rotary airlocks and sealing devices used to move material between zones of different air pressure (like from a negative-pressure cleaner to an ambient-pressure output).