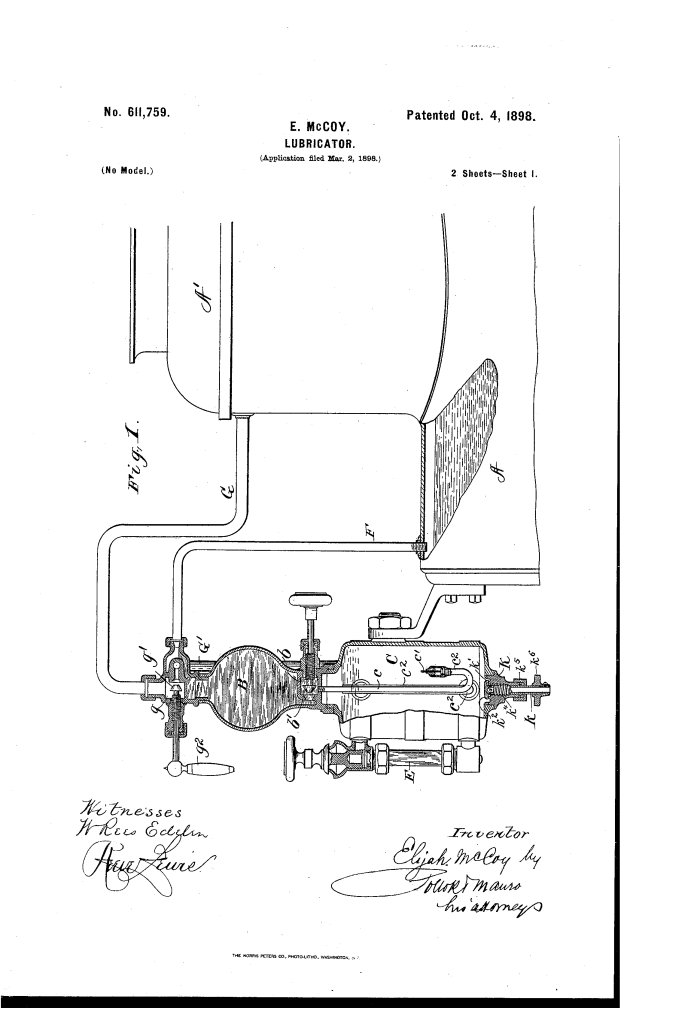

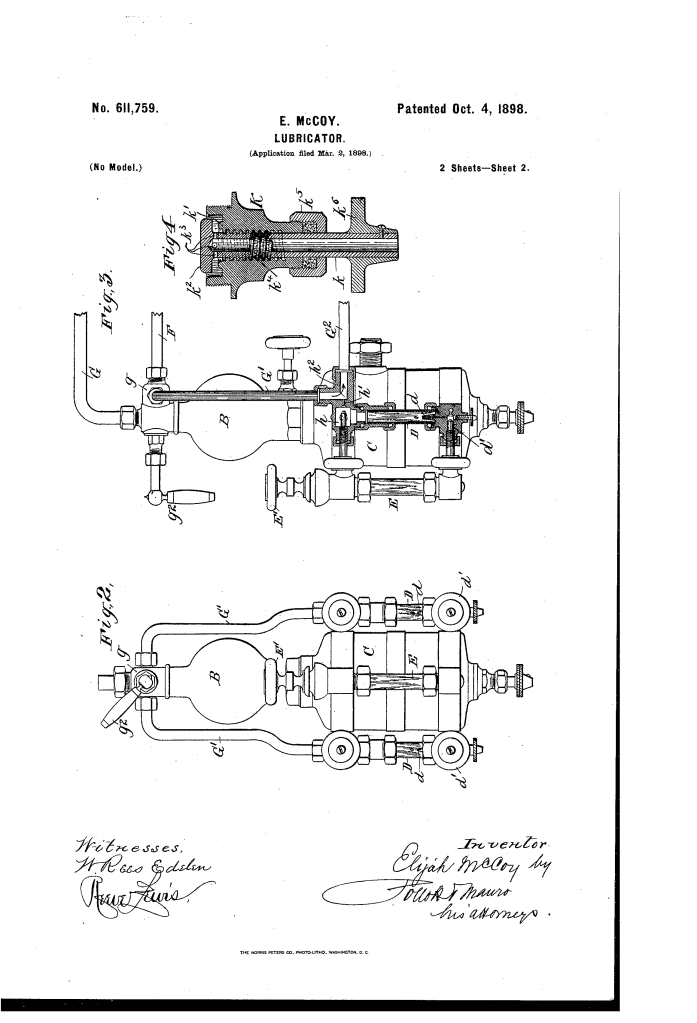

The patent by Elijah McCoy of Detroit, Michigan, describes a new and useful Improvement in Lubricators (Patent No. 611,759, 1898), designed particularly for locomotive-engines. The invention aims to remedy certain defects in existing sight-feed lubricators, primarily the uncertainty and irregularity of the oil feed caused by fluctuating steam pressure and clogging.

Inventor Background: Elijah McCoy

Elijah McCoy (1844–1929) was an exceptionally prolific African-American inventor and engineer who held over 57 patents, mostly related to automated lubrication and railway technology. McCoy’s work revolutionized industrial efficiency by allowing machinery to be lubricated continuously while running, giving rise to the famous phrase, “the real McCoy.” This patent is part of his sustained effort to refine sight-feed lubricators for locomotive use, enhancing their reliability under the extreme conditions of railway operation.

Invention and Mechanism

The improved lubricator uses entirely independent steam supplies for the condensing (water feed) and the propulsion (oil atomizing) functions, and features a specialized drain valve to prevent accidental opening.

1. Independent Steam Systems (Key Innovation)

- Condenser Supply (Water Feed): Steam for the condenser (B) is supplied by pipe (F). This steam condenses to create the hydrostatic column pressure needed to displace the oil.

- Note: This supply is disconnected from the overpressure supply.

- Overpressure/Propulsion Supply (Steam Feed): Live steam for atomizing and propelling the oil is supplied by an independent pipe (G), preferably from the steam-dome () of the boiler, ensuring a strong, consistent flow.

- Crucial Difference: This overpressure steam connects directly with the tallow-pipe () at its junction with the sight-feed chamber () (in front of the nozzle

). In older designs, steam often connected behind a contracted atomizing-nozzle, leading to choking and retardation.

- Crucial Difference: This overpressure steam connects directly with the tallow-pipe () at its junction with the sight-feed chamber () (in front of the nozzle

2. Enhanced Oil Feed and Atomization

- Location of Steam Injection: The live steam joins the oil in front of the feed nozzle (

), allowing the oil to pass freely through the nozzle. The steam’s energy then meets the oil at the elbow of the sight-feed arm ().

- Function: This location avoids the contracted channels that cause clogging and ensures a high-energy current of steam is available to effectively draw and subdivide (atomize) the oil into the tallow-pipe (

), even against high opposing steam-chest pressure.

- Function: This location avoids the contracted channels that cause clogging and ensures a high-energy current of steam is available to effectively draw and subdivide (atomize) the oil into the tallow-pipe (

3. Preventing Backflow and Siphonage

- Puppet Valve (): The water-feed pipe (c) leading into the oil reservoir (C) is upturned and provided with a weighted puppet-valve ().

- Function: This valve is designed to close automatically against any back pressure or when a partial vacuum forms in the boiler (siphonage), which would otherwise cause oil loss or backflow contamination.

- Trap (): The pipe bend (

) forms a trap, designed to always be filled with water, which further prevents oil from floating off into the water-feed system.

4. Improved Drain-Valve

- Reverse Operation: The drain-valve (

) is designed to close downwardly upon its seat.

- Left-Hand Threads (): The valve-stem uses left-hand threads in the body.

- Function: This innovative combination ensures that the natural vibration and internal pressure (which tend to loosen conventional valves) instead force the valve to turn in the direction to close the disk more tightly against its seat, making the valve significantly more reliable and preventing accidental opening.

Concepts Influenced by This Invention

McCoy’s lubricator established critical standards for reliability and flow control in high-pressure industrial systems.

- Independent Fluid/Gas Circuits: The core principle of using separate, independent circuits for fluid pressure (condenser water) and fluid propulsion/atomization (live steam) influenced the design of all modern industrial systems requiring precise flow. This allows one function to be controlled or fail without disrupting the power required for the other.

- Vapor/Fluid Interface Design: The design to join the oil and high-pressure steam at an angular elbow or interface (in front of the nozzle) rather than forcing them through a restriction influenced the design of modern venturi jets and atomizing nozzles used in fuel injection, humidification, and spray systems, ensuring efficient mixing and minimal choking.

- Pressure-Assisted Sealing/Locking: The reverse-threaded, downward-closing drain valve is a major mechanical influence. This design principle of ensuring that the internal pressure acts to tighten (seal) or lock a component rather than loosening it is utilized in various modern high-pressure safety valves and thread-locking mechanisms.

- Sight-Feed Metering: The reliance on the sight-feed glass (D) for visual regulation and the push for reliability in this metering system influenced the design of all modern controlled-drip oilers and fluid dispensers.