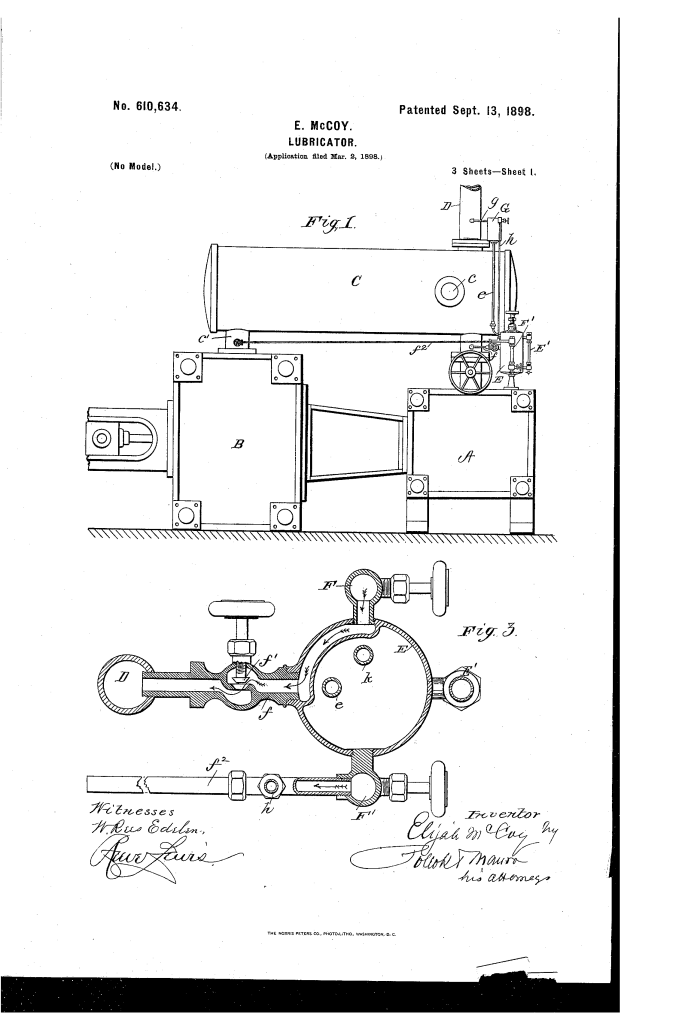

The patent by Elijah McCoy of Detroit, Michigan, describes an Improvement in Lubricators (Patent No. 610,634, 1898), specifically for multiple-expansion steam-engines. The invention addresses a critical defect in existing lubricators where the oil intended for all cylinders would be incorrectly drawn primarily to the low-pressure cylinder, leaving the high and intermediate cylinders unlubricated.

Inventor Background: Elijah McCoy

Elijah McCoy (1844–1929) was an exceptionally prolific African-American inventor whose work revolutionized industrial lubrication. Known as the source of the phrase “the real McCoy,” his innovations aimed at ensuring continuous, reliable lubrication for machinery, particularly on locomotives and other steam-powered equipment. This patent represents a highly specialized solution tailored for the most complex steam engines of the era.

Invention and Mechanism

The core innovation is providing independent steam-propulsion passages for the oil leading to the low and intermediate pressure cylinders, thereby isolating the oil feed lines from pressure imbalances.

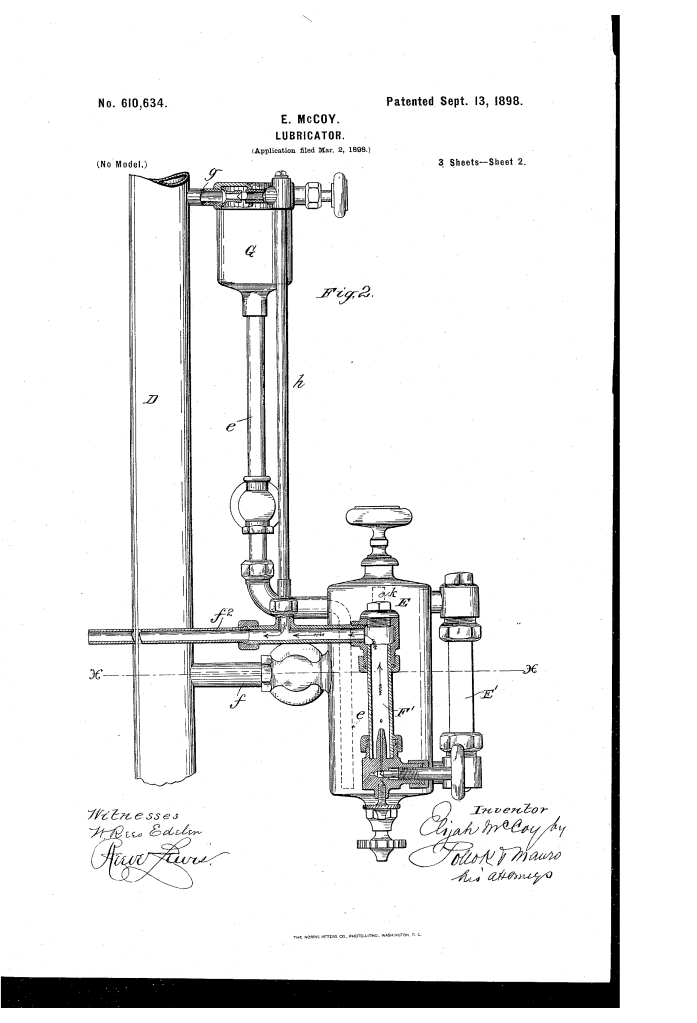

1. The Problem of Unequal Pressure

- Multiple-Expansion Engine: These engines use a sequence of cylinders (High, Intermediate, Low) where steam pressure drops significantly from one cylinder to the next.

- The Defect: In old lubricators, a single auxiliary steam source branched out to all oil feed pipes. Because the low-pressure cylinder offered the path of least resistance (lowest steam pressure), nearly all the propelling steam and lubricant would flow there, starving the high and intermediate cylinders.

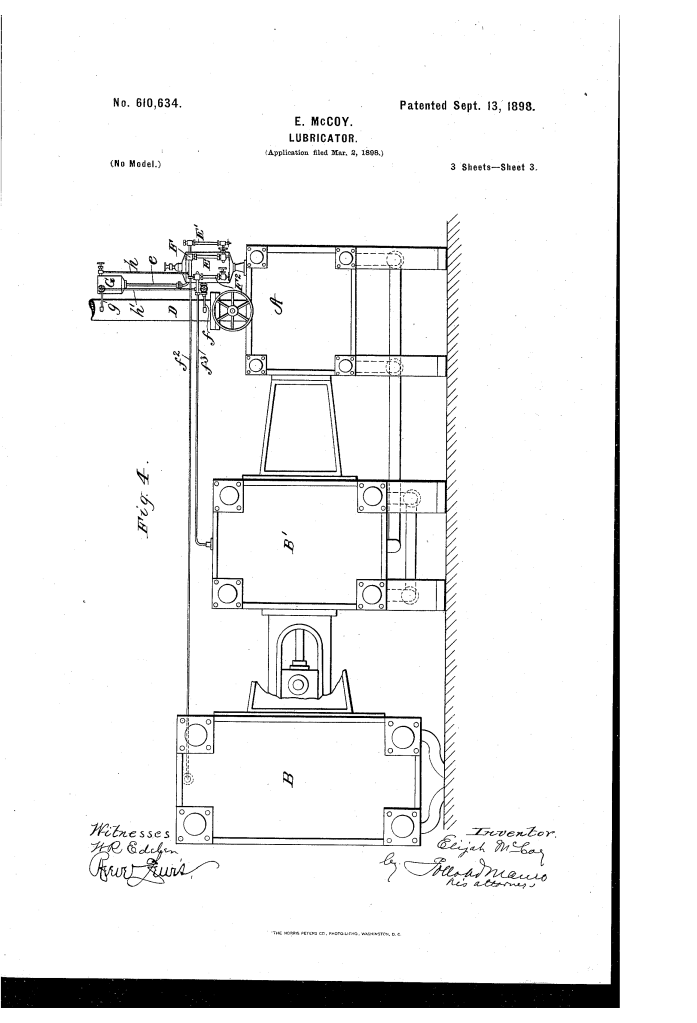

2. Independent Auxiliary Steam Pipes (Key Innovation)

- High-Pressure Cylinder (A) Feed: The oil feed pipe ($f$) for the high-pressure cylinder is left to rely on the slight suction created by the main steam-pipe flow, as this is sufficient.

- Low and Intermediate Cylinder Feed ($B, B’$):Independent auxiliary steam pipes ($h, h’$) are provided, one for each low/intermediate pressure cylinder.

- Connection (Lower End): Each auxiliary pipe leads into the respective oil-feed pipe ($f’, f”$) for the low/intermediate cylinder.

- Connection (Upper End): Crucially, the auxiliary steam pipes ($h, h’$) are connected independently (not branched from a common source) to the upper part of the condenser (G) or directly to the main steam-pipe at a point significantly elevated above the inlet for the high-pressure oil.

3. Operational Advantages

- Flow Isolation: By using independent steam feeds for the low/intermediate cylinders, the defective communication path between the high and low-pressure oil feeds is eliminated.

- Balanced Lubrication: Each cylinder receives its proper, proportioned quantity of oil, irrespective of the pressure differences between the cylinders.

- Convenience: Tapping the auxiliary steam pipes into the upper part of the condenser (G) provides a convenient surface for connection, simplifying application to existing lubricators.

Concepts Influenced by This Invention

McCoy’s design influenced subsequent fluid distribution systems by pioneering a solution for precise flow management under conditions of severe pressure gradient.

- Pressure-Compensated Distribution: The core principle of providing independent motive force (steam jet) to each outlet of a fluid distribution system, rather than relying on a single shared source, influenced the design of modern flow control and distribution manifolds used in chemical processing, hydraulics, and pneumatics where unequal resistance between output lines must be compensated for to ensure accurate dosing.

- Independent Flow Segregation: The solution reinforced the engineering principle that, under conditions of severe pressure differential, fluid systems must be physically segregated (using independent pipes $h, h’$) rather than simply branched from a common source to maintain reliable flow into zones of lower pressure.

- Zoned Fluid Supply: The concept of sourcing the auxiliary steam from a point elevated above the main oil inlet to prevent backward contamination influenced the design of modern fluid reservoirs that use zoned plumbing to separate high-pressure return lines from low-pressure feed lines for safety and system integrity.

- Solving Systemic Defects: This patent represents a significant achievement in diagnosing and correcting a fundamental, previously misunderstood defect in an entire class of industrial machinery.