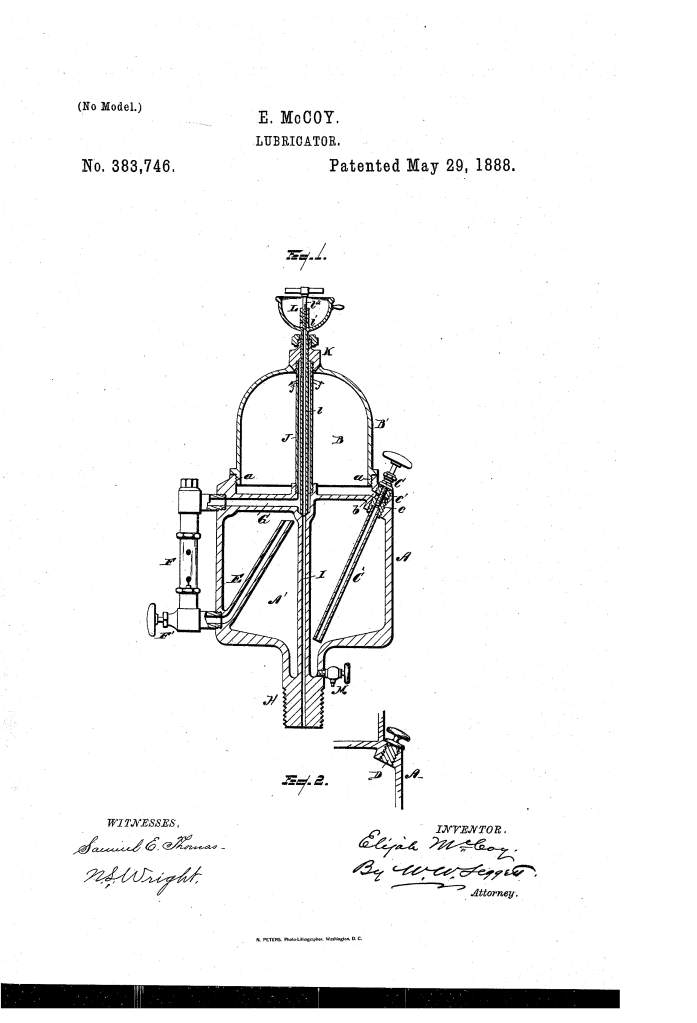

Lubricator (Elijah McCoy, No. 383,746)

The patent by Elijah McCoy of Detroit, Michigan, describes an improved Lubricator (Patent No. 383,746, 1888). This invention is an automatic “sight-feed” oiling device for steam engines. Its primary objective was to ensure the continuous lubrication of engine cylinders even if the glass sight-feed tube—the part that allows the engineer to see the oil dripping—accidentally broke. McCoy’s design combined a sight-feed and a blind-feed lubricator into a single, self-contained unit, eliminating the need for engineers to carry expensive spare parts.

Inventor Background: Elijah McCoy

Elijah McCoy (1844–1929) was a legendary African American inventor and engineer, often associated with the phrase “The Real McCoy” due to the high quality and reliability of his designs. Born in Canada to parents who had escaped slavery, McCoy trained as a mechanical engineer in Scotland. His work revolutionized the railroad and shipping industries by allowing engines to be lubricated while in motion, rather than having to stop for manual oiling. This 1888 patent represents a sophisticated evolution of his earlier designs, focusing on fail-safe mechanisms and integrated thermal management.

Key Mechanical Components & Functions

The lubricator uses steam condensation to displace oil and a clever dual-conduit system for “emergency” oiling.

1. The Condensing and Oil Chambers (B, A)

- Condensing Chamber (B): Steam enters the upper chamber and cools into water.

- Oil Chamber (A): This chamber holds the main oil supply.

- Displacement Principle: Water from the condenser travels through a passage (b) controlled by a valve (c). Because oil is lighter than water, the incoming water sinks to the bottom, forcing the oil to rise to the top of the chamber.

2. The Sight-Feed Glass (F)

- Visible Monitoring: Oil is permitted to escape through an exit-tube (E) into the sight-feed glass (F).

- Function: This allows the engineer to monitor the exact rate of lubrication. The oil then travels through a lateral passage (G) and down a central conduit (I) to the steam cylinder.

3. The Slush-Cup and Hollow Stem (L, l) (Key Innovation)

This is the “emergency” or “blind-feed” system.

- Slush-Cup (L): A cup at the top of the device with its own valve (l)*.

- Hollow Stem (l): The cup is attached to a long stem that passes through the condensing chamber via a wider steam-pipe (J).

- The Fail-Safe: Normally, the stem is lifted to allow oil from the sight-glass to flow. However, if the glass breaks, the engineer can seat the stem (screw it down).

- Blind-Feed Action: Seating the stem cuts off the broken sight-glass and creates a direct, enclosed path from the slush-cup to the conduit (I). The engineer can then manually add oil to the cup, serving the function of a “blind-feed” lubricator.

4. The Perforated Steam Pipe (J)

- Dual Function: The pipe (J) surrounding the slush-cup stem is perforated with orifices (j).

- Function: This allows steam to ascend around the stem and enter the condensing chamber. This compact “tube-within-a-tube” design saves space and ensures that the steam stays hot enough to keep the oil in the slush-cup fluid even in cold weather.

Improvements Over Previous Lubricators

| Feature | Standard 1880s Lubricators | McCoy’s Improved Lubricator |

| Reliability | Breaking the sight-glass meant the engine had to stop. | Built-in “blind-feed” allows operation to continue. |

| Complexity | Required separate oil reservoirs and blind-cups. | Complete, self-contained unit with integrated chambers. |

| Ease of Use | Required draining water before manual oiling. | Slush-cup feeds directly to the conduit; no draining needed. |

| Cost | High expense for spare “blind-feed” parts. | Economical “two-in-one” design. |

Significance to Engineering and Industry

Elijah McCoy’s lubricator influenced the development of fail-safe mechanical systems and fluid dynamics in heavy machinery.

- Fail-Safe Engineering: By integrating a secondary manual path into an automatic system, McCoy pioneered the concept of redundancy, which is a core principle in modern aerospace and industrial safety.

- The “Real McCoy” Standard: His lubricators were so much more reliable than those of his competitors that engineers specifically requested “the Real McCoy” to ensure their locomotives wouldn’t seize up on long hauls.

- Hydrostatic Lubrication: This patent perfected the use of displacement lubrication, a technique still understood today in various gravity-fed and pressure-differential oiling systems.

- Thermal Integration: The use of steam to pre-heat the oil in the slush-cup (via pipe J) demonstrated a sophisticated understanding of heat transfer, ensuring the device worked reliably in the harsh, variable environments of outdoor railroading.