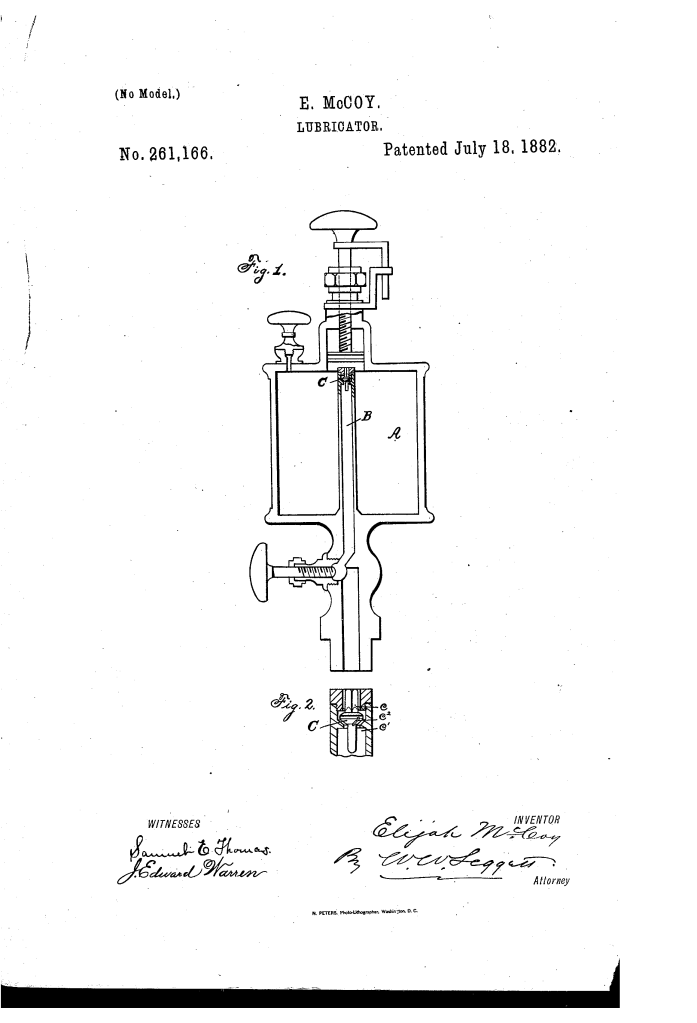

The patent by Elijah McCoy of Detroit, Michigan, describes an Improvement in Lubricators (Patent No. 261,166, 1882). The invention is designed primarily for locomotive-engines and aims to solve the problem of oil waste that occurs when the engine shuts off steam and begins to “work a vacuum.”

Inventor Background: Elijah McCoy

Elijah McCoy was an exceptionally prolific African-American inventor whose work on automatic oiling devices was foundational to industrial efficiency. This patent is a crucial addition to his portfolio, focusing on creating a valve that is multifunctional: it must prevent massive oil waste during a vacuum, but still allow a small, necessary amount of oil to feed the engine.

Invention and Mechanism (Simplified)

The lubricator features a specialized double check-valve located at the top of the oil discharge pipe. This valve operates differently depending on whether the engine is applying pressure or creating a vacuum.

- The Double Valve (G): A free-moving check-valve placed at the extreme upper end of the oil-exit pipe (B).

- Stopping Oil Waste (Vacuum Check):

- Action: When the engine shuts off steam, a vacuum forms in the cylinder, sucking air (and oil) out of the lubricator. This causes the valve (G) to close down instantly onto its lower seat.

- Function: This closure prevents the oil from being sucked out and wasted from the cup.

- Controlled Leak (Lubrication During Vacuum):

- Groove: The valve’s lower face (or its seat) is cut with a small groove.

- Function: When the valve is closed (during the vacuum), this small groove still affords a tiny, controlled outlet for a sufficient quantity of oil to lubricate the cylinder as it operates without steam. This controlled leak replaces the previously wasted mass of oil.

- Preventing Over-Feed (Steam Surge Check):

- Upper Serrated Seat: The valve (G) is provided with an upper serrated seat.

- Action: When steam suddenly surges back into the lubricator from the cylinder, the force lifts the valve (G) and holds it against the upper serrated seat.

- Function: The serrations impede the free passage of oil, neutralizing the tendency for a large quantity of oil to be suddenly “driven out” by the steam surge.

Core Concepts Influenced by This Invention

McCoy’s double valve influenced subsequent fluid control systems by establishing principles for differential and controlled-leak flow management under dynamic pressure.

- Differential Check Valve: The core concept of a single valve having two distinct seating positions (upper serrated seat for pressure surge, lower solid seat for vacuum) with two different flow rates (slow leak vs. impeded flow) influenced the design of modern:

- Hydraulic Control Valves: Which use differential areas and multiple seating surfaces to manage pressure fluctuations and flow regulation.

- Controlled Leak/Bleed-Off: The inclusion of the small groove on the lower seat to establish a precisely controlled minimal flow when the valve is otherwise fully closed influenced the design of various bypass and bleed-off valves used in fluid systems to maintain lubrication or pressure even in the system’s “off” state.

- Flow Impedance by Serration: The use of a serrated seat to purposefully impede fluid flow when the valve is lifted influenced the design of specialty industrial valves and regulators where flow must be throttled or slowed down during a transient pressure state.

- Maximized Operational Position: Locating the valve at the extreme upper end of the oil-exit pipe to minimize the liquid column’s interference influenced the general engineering practice for placing sensitive control elements in fluid systems.