The patent by Elijah McCoy of Detroit, Michigan, describes a new and useful Improvement in Lubricators (Patent No. 255,443, 1882), designed especially for use on the cylinders of locomotives. The invention aims to prevent the waste of oil that occurs when the engine is stopping and begins to “pump a vacuum.”

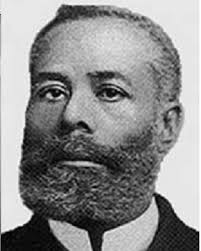

Inventor Background: Elijah McCoy

Elijah McCoy (1844–1929) was an exceptionally prolific African-American inventor whose work on automatic oiling devices was essential to rail and industrial efficiency. This patent is a crucial addition to his portfolio, addressing a known flaw in existing sight-feed lubricators that caused significant, expensive oil waste when steam power was cut off.

Invention and Mechanism (Simplified)

The lubricator is a sight-feed system with a movable internal partition that controls how much oil is available to be instantly sucked out when the engine stops.

- The Problem: When a locomotive cuts steam (e.g., coasting or stopping), the engine’s movement suddenly creates a vacuum in the lubrication pipes. This instantly sucks out and wastes any oil that has accumulated above the top of the oil discharge pipe. This “waste” was not controlled and could be massive.

- Adjustable Plunger (D) (Key Innovation): A plunger or piston is installed in the top section of the oil cup. This plunger is attached to an adjustable stem ($D’$) accessible from the exterior.

- Oil Accumulation Control: The plunger (D) acts as a movable partition, separating an upper extension (C) of the oil chamber.

- Function: By adjusting the plunger’s height, the engineer can precisely regulate the size of the space (C) above the discharge pipe’s opening. This space dictates the exact, controlled amount of oil that can accumulate and be sucked out when the vacuum occurs. This turns waste into a graduated, controlled dose.

- Adjustable Condensing Surface: The adjusted space (C) also functions as the condensing-chamber (where steam turns to water to float the oil). Adjusting its size allows the engineer to control the rate of condensation (slower in winter, faster in summer) for optimum feed speed.

- Protected Indicator:

- Slotted Casing (F): A slotted metal casing surrounds the fragile glass indicator tube.

- Slotted Sleeve ($F’$): A similarly slotted movable metal sleeve surrounds the casing (F).

- Function: The engineer can partially rotate the sleeve ($F’$) to expose the glass tube for observation, or rotate it back to totally incase and protect the glass from accidental breakage.

Core Concepts Utilized Today

McCoy’s lubricator influenced subsequent industrial and hydraulic designs by pioneering adjustable displacement and flow management controls.

- Adjustable Volume Dosing: The core concept of using an adjustable physical barrier (Plunger D) to regulate the maximum volume of fluid available for immediate discharge influenced the design of modern fluid dispensers, metering pumps, and reservoirs that require precise, controlled volume delivery.

- Dynamic Condensation Surface Control: The idea of making the condensing surface adjustable to control the system’s reaction time based on ambient temperature influenced the design of various industrial thermal systems and control valves that need to be calibrated for environmental variability.

- Protected Visual Indicators: The rotating, slotted sleeve system ($F’$) for protecting a fragile component (the sight glass) while still allowing quick viewing influenced the design of protective covers for modern industrial gauges, meters, and viewing ports in harsh environments.