Insect-Destroyer (Albert C. Richardson, No. 620,362)

The patent by Albert C. Richardson of South Frankfort, Michigan, describes a new and useful Insect-Destroyer (Patent No. 620,362, 1899). The invention is a mobile apparatus for generating and applying smoke and fumes to destroy insects on plants and trees without injuring the tender shoots or foliage.

Inventor Background: Albert C. Richardson

Albert C. Richardson was an African-American inventor from Michigan known for solving practical problems with ingenious mechanical designs, such as his Casket-Lowering Device (No. 529,311) and an adjustable Bottle (No. 638,811). This patent shows his focus on agricultural and gardening utility, creating a specialized, adjustable tool for pest control.

Invention and Mechanism

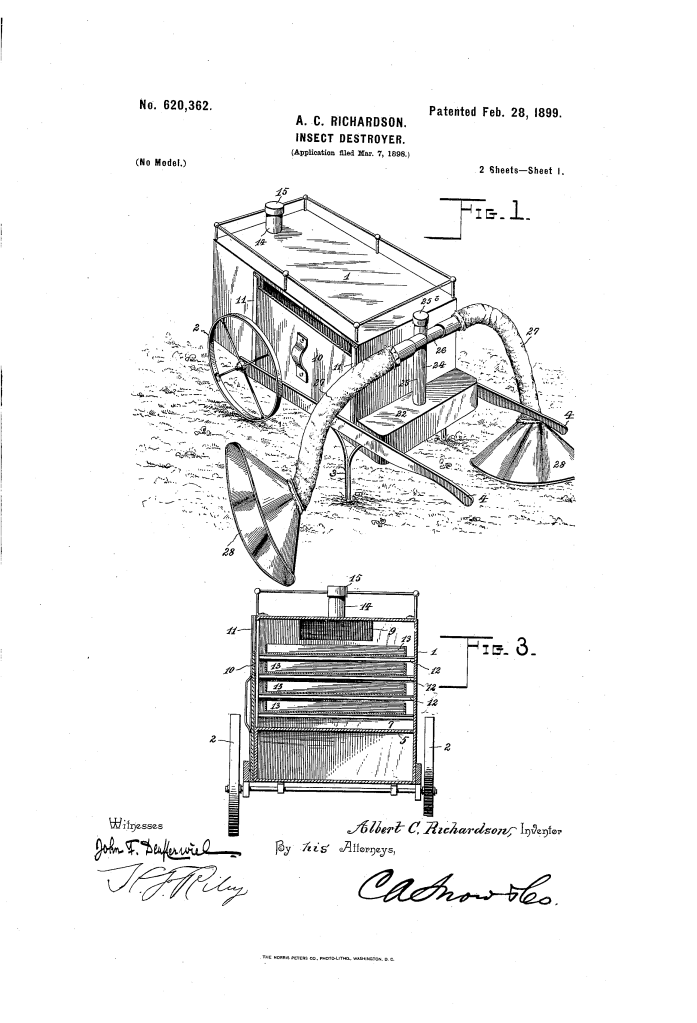

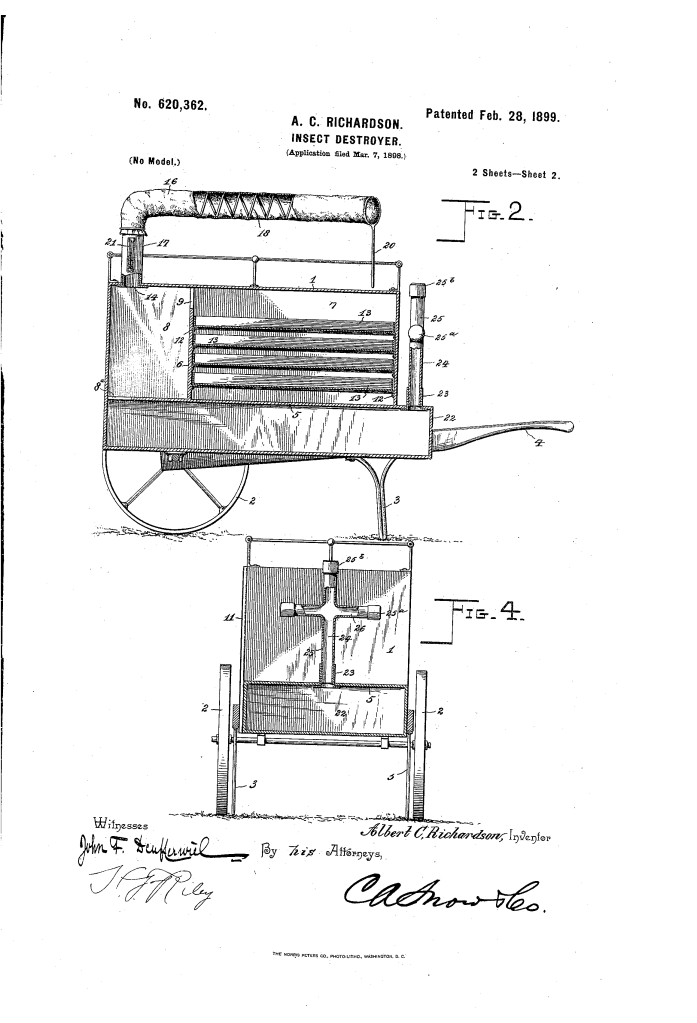

The insect-destroyer is a mobile, compartmentalized machine that offers two distinct modes of operation: direct hot smoke and cooled smoke.

1. Mobile Frame and Combustion

- Mobile Casing (1): A rectangular sheet-metal casing mounted on wheels (2) at one end and legs (3) with handles (4) at the other, adapting it for movement like a wheelbarrow.

- Main Chamber (7): Contains the burning material (e.g., tobacco) for smoke production.

- Draft Control: A sliding door (10) is arranged at the top of one side. The door is positioned to force the draft to pass over the burning material, causing the fire to burn slowly and produce a greater quantity of smoke than a simple bottom draft.

2. Smoke Cooling System (Key Innovation for Tender Plants)

- Cooling-Chamber (8): A rear compartment intended to contain ice or water.

- Flow Path: Hot smoke/fumes pass from the main chamber (7) into the cooling-chamber (8), and then into a lower smoke-conduit space (beneath partition 5).

- Function: By passing through the ice/water-cooled compartment, the smoke’s temperature is reduced sufficiently to be discharged without scorching tender shoots or foliage.

3. Discharge and Application System (Dual-Mode Output)

- Vents and Modes: The casing has two discharge options:

- Direct Discharge: Smoke exits directly from the top vent (14) of the main chamber (7) (hot smoke).

- Cooled Discharge: Smoke passes through the cooling chamber and exits from the front vent (23) of the lower conduit (cool smoke).

- Cross-Shaped Coupling (24) for Row Operations: The cooled-smoke vent (23) connects to a cross-shaped coupling (24) with two horizontal arms (26).

- Function: This coupling is designed to simultaneously connect a pair of discharge-pipes (27) with funnel-shaped nozzles (28). This setup allows the operator to work between two rows of plants, subjecting both rows to treatment simultaneously for maximum efficiency.

Concepts Influenced by This Invention

Richardson’s Insect-Destroyer influenced subsequent industrial and agricultural equipment by pioneering temperature-controlled, mobile fluid delivery systems.

- Temperature-Controlled Fluid Delivery: The core concept of using a dedicated chamber filled with a cooling medium (ice/water 8) to reduce the temperature of a gas (smoke) before application influenced the design of modern agricultural sprayers, ventilation systems, and industrial scrubbers that require cooling or conditioning of a chemical or gas before it contacts sensitive surfaces.

- Integrated Dual-Mode Functionality: The ability to select between direct, hot output and cooled output by choosing the discharge vent influenced the design of industrial application tools that require variable process parameters (e.g., high-heat sterilization vs. low-heat drying).

- Simultaneous Multi-Row Application: The use of the cross-shaped coupling (24) for simultaneous, dual-pipe application influenced the design of modern agricultural boom sprayers and irrigation systems that use multiple parallel discharge nozzles to treat large areas or multiple rows efficiently.

- Mobile, Compartmentalized Processing: The design of a wheelbarrow-like mobile chassis with distinct, separated compartments (combustion, cooling, smoke