Lawn-Sprinkler (Joseph H. Smith, No. 601,065)

The patent by Joseph H. Smith of Washington, D.C., describes an improved Lawn-Sprinkler (Patent No. 601,065, 1898). This is a modified version of his earlier design, with the primary objects being to provide a simple, inexpensive sprinkler free of parts liable to break, and to enable a large area to be sprinkled by a single device.

Inventor Background: Joseph H. Smith

Joseph H. Smith was an inventor focusing on efficient fluid management and domestic utility. This patent is a refinement of his previous work on converting water pressure into rotational motion for sprinklers. His design philosophy centered on mechanical simplicity (using minimal or no internal moving parts) to increase durability and maintain a low manufacturing cost.

Invention and Mechanism

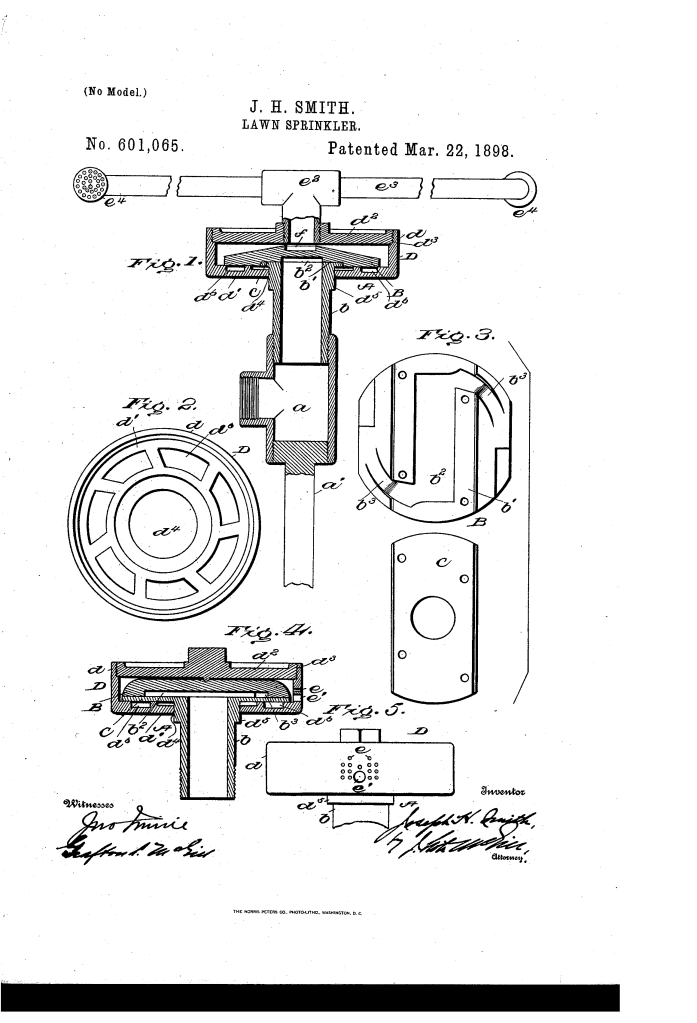

The sprinkler is a stationary, single-moving-part device that uses a channeled stationary base to drive a rotary head with integrated buckets.

1. Stationary Head and Water Drive (Key Innovation)

- Support: The unit is staked into the ground via a supporting rod ($a’$). Water enters through a T-joint ($a$).

- Stationary Head (B): This head is fixed and is the core of the drive system. Its underside has a wide transverse groove ($b’$ ) and a cut-out ($b^{2}$), forming a water channel.

- Ports ($b^{3}$): The water channel opens into two lateral, oppositely-extended ports ($b^{3}$), which are the drive nozzles.

- Plate (C): A flat plate, preferably integral with the supply pipe, fits over the groove ($b^{2}$), sealing the channel and directing the water flow out through the two ports ($b^{3}$).

2. Rotary Head and Distribution

- Rotary Head (D): A circular head with a rim ($d$), a bottom ($d’$), and a removable top ($d^{2}$). It is loose to revolve around the stationary head (B).

- Buckets (d6): The inner face (bottom $d’$) of the rotary head has a circular series of grooves ($d^{6}$) with inclined bottoms, forming buckets.

- Function (Self-Propulsion): The water discharged in opposite directions from the stationary ports ($b^{3}$) strikes these buckets ($d^{6}$), causing the head (D) to rotate continuously.

- Water Discharge: Water finds its escape either through a series of perforations ($e$) in the rim ($d$) (for ordinary purposes) or, for large-area sprinkling, through a central opening with a T-joint ($e^{2}$) leading to two small, oppositely-faced sprayers ($e^{4}$).

Concepts Influenced by This Invention

Smith’s sprinkler influenced subsequent fluid power and rotary drive systems by pioneering a highly simplified, passive impulse drive mechanism for consumer products.

- Impulse Turbine/Pelton Wheel Principle: The core concept of using oppositely-directed water jets to impinge upon a series of buckets (d6) fixed to a rotor to generate efficient, continuous torque is a simple application of the Pelton wheel or impulse turbine principle. This simplified design influenced the manufacturing of low-cost, self-propelled rotating devices for consumer markets.

- Channelized Fluid Drive: The use of a channel (b2) in the stationary part to precisely direct the fluid stream against the moving buckets influenced the design of various miniature fluid motors, meters, and low-pressure rotary actuators.

- Elimination of Internal Moving Parts: By relying solely on the momentum of the water jets and fixed buckets to achieve rotation (with only the head D moving), the design minimized complexity and wear points, a principle influencing all high-durability, low-maintenance consumer utilities.

- Modular Distribution Output: The option to swap the simple perforated rim with a T-joint and external sprayers ($e^{3}, e^{4}$) influenced the design of modern modular tools that allow the user to easily change the output mechanism (e.g., spray pattern, flow rate) on a single drive unit.