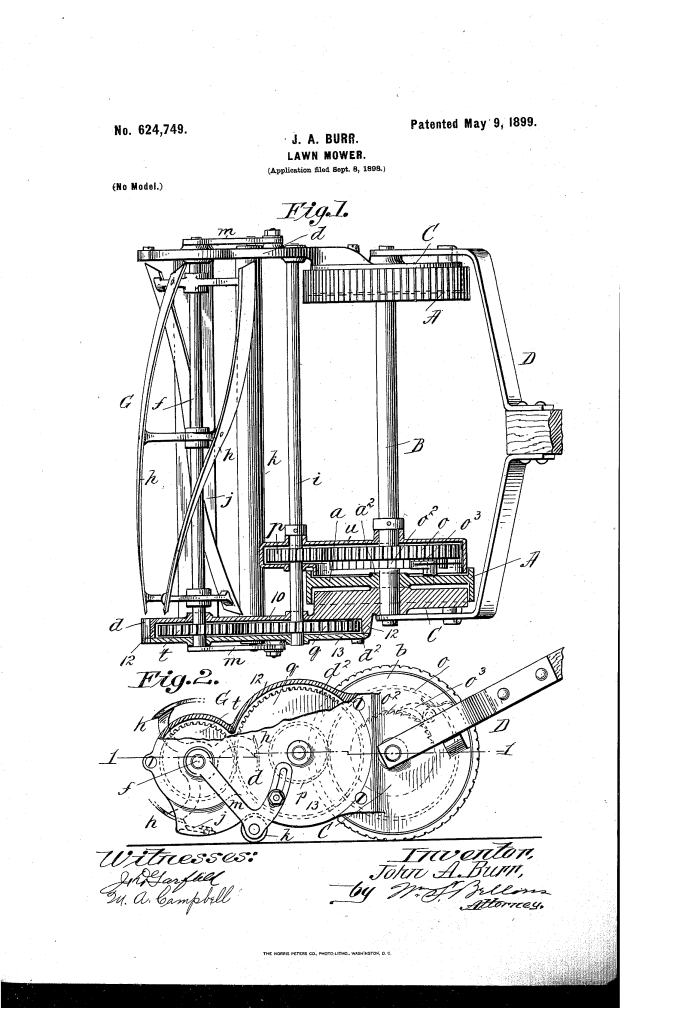

Lawn-Mower (John Albert Burr, No. 624,749)

The patent by John Albert Burr of Agawam, Massachusetts, describes an improved Lawn-Mower (Patent No. 624,749, 1899). The invention focuses on addressing two common problems in lawn-mower design: gearing contamination and uneven cutting width that leaves uncut strips next to the wheels.

Inventor Background: John Albert Burr

John Albert Burr was an African-American inventor who focused on utility and mechanical efficiency, particularly for agricultural and domestic tools. His work addressed the practical frustrations of lawn-mower maintenance and operation, making the cutting process cleaner, wider, and less prone to mechanical failure.

Invention and Mechanism

The improved lawn-mower features an extended rotary cutter and a fully enclosed gear system housed within offset cheek-plates.

1. Enclosed Gearing (Key Innovation for Durability)

- Traction Wheels (A, A) and Cheek-Plates (C, C): The wheels are fixed to the shaft (B). The cheek-plates form the main housing.

- Cup-Like Wheels: The wheels are constructed with wide rims and are slightly cup-like, with narrow hub portions ($a’$).

- Internal Housing: The circular portion ($b$) of each cheek-plate is disposed well within the cup-like traction wheels (A).

- Casing: A chambered shell or casting ($u$) is provided to wholly inclose the operating gearing (the ratchet, gear wheels $o, p, q, t$).

- Function: This complete enclosure prevents the gearing from becoming choked by grass or clogged by obstructions of any kind, which historically caused frequent mechanical failure and required cleaning.

2. Extended Cutter Bar (Wide Swath)

- Offset Cheek-Plate Extensions ($d, d$): The forward portions of the cheek-plates (C, C) are decidedly outwardly offset (pushed out) beyond the outer faces of the traction wheels.

- Long Rotary Cutter (G): The shaft ($f$) of the rotary cutter (G) is mounted between these offset extensions. The cutter knives ($h$) are unusually long, exceeding the distance between the outer faces of the traction wheels (A, A).

- Function: This arrangement allows the machine to cut the grass in a path wider than that comprised between the traction-wheels. This overcomes the disadvantage of having the wheel itself bed down the grass just outside of the cut path at every pass, which would necessitate overlapping cuts and waste time.

3. Power Train

- Ratchet Drive: A spring-pawl ($o^{2}$) on the inner face of one traction wheel engages a ratchet wheel ($o’$), causing the gear wheel ($o$) to rotate only when the machine is pushed forward. This drives the counter-shaft ($i$) and the rotary cutter shaft ($f$) through a series of reduction gears, achieving rapid rotation of the cutting blades ($h$).

Concepts Influenced by This Invention

Burr’s lawn-mower influenced subsequent mechanical design by establishing principles for environmental sealing and optimizing the tool-to-frame ratio in cutting and harvesting equipment.

- Sealed Gearing/Drive Train: The core concept of fully enclosing the operating gearing within a protective housing (cheeks C and casing $u$) to prevent contamination by the material being processed (grass, dirt, debris) influenced the design of all modern heavy-duty tools and machinery, such as chainsaws, trimmers, and industrial gearboxes that operate in dirty environments.

- Wide-Cut/Offset Blade Geometry: The design philosophy of offsetting the cutting mechanism (G) outside the plane of the traction mechanism (A) so the cut swath is wider than the wheel track influenced the design of modern agricultural and commercial mowers and harvesters. This geometric arrangement maximizes efficiency by eliminating uncut strips (or “bedding down”) caused by the wheels.

- Integrated Housing Design: The use of the cheek-plates (C) themselves to form the bearings and the structural housing for the gear train influenced the design of complex mechanical casings where structural support, bearing mounts, and environmental protection are consolidated into minimal components.