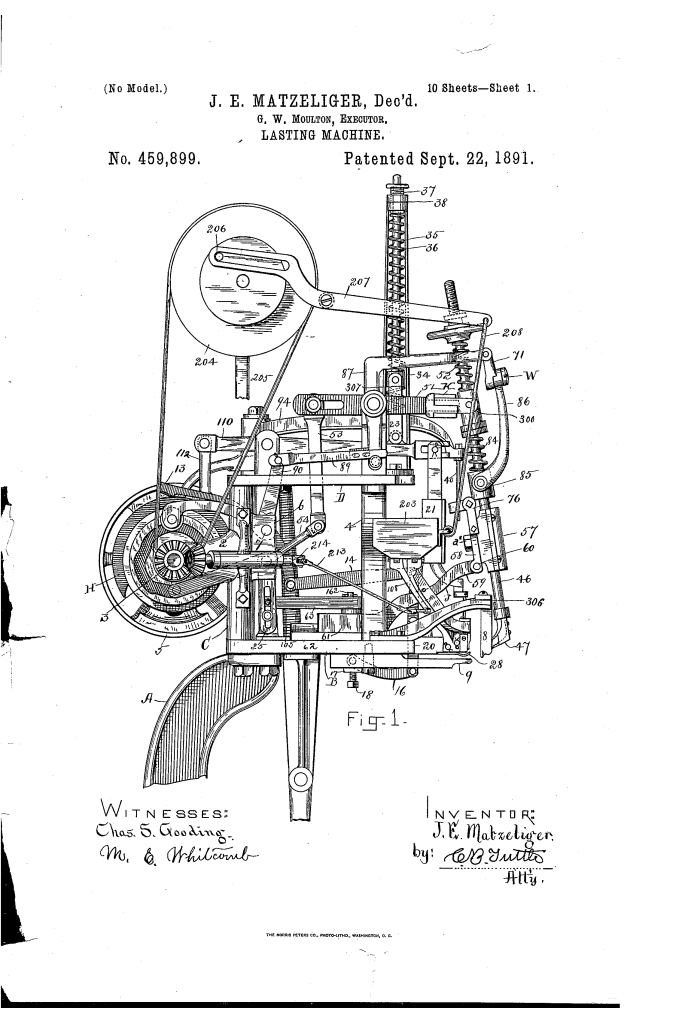

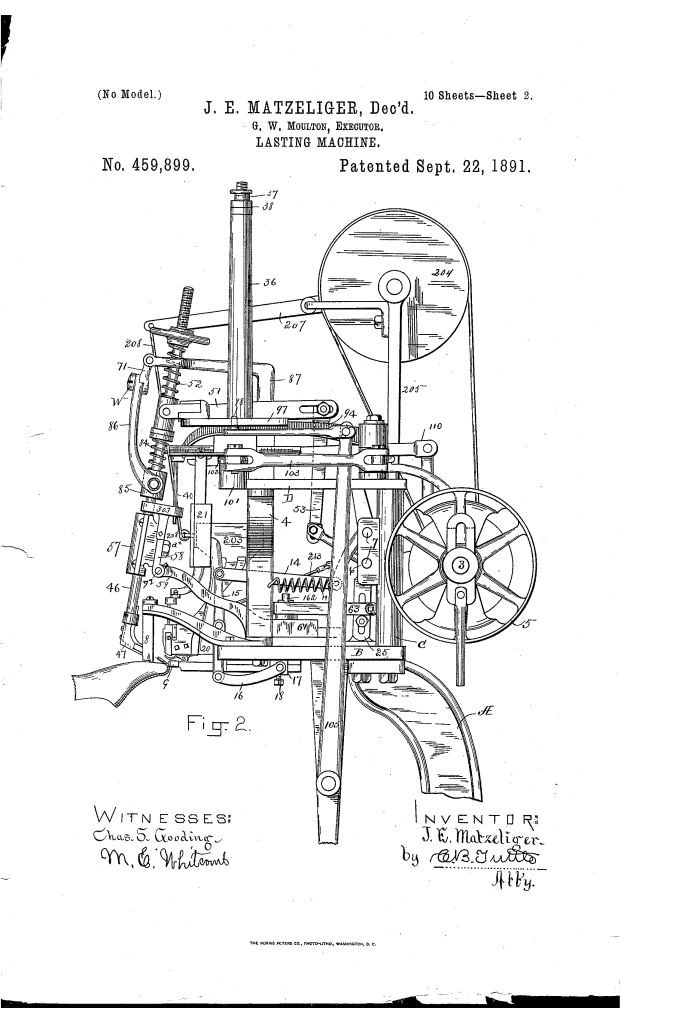

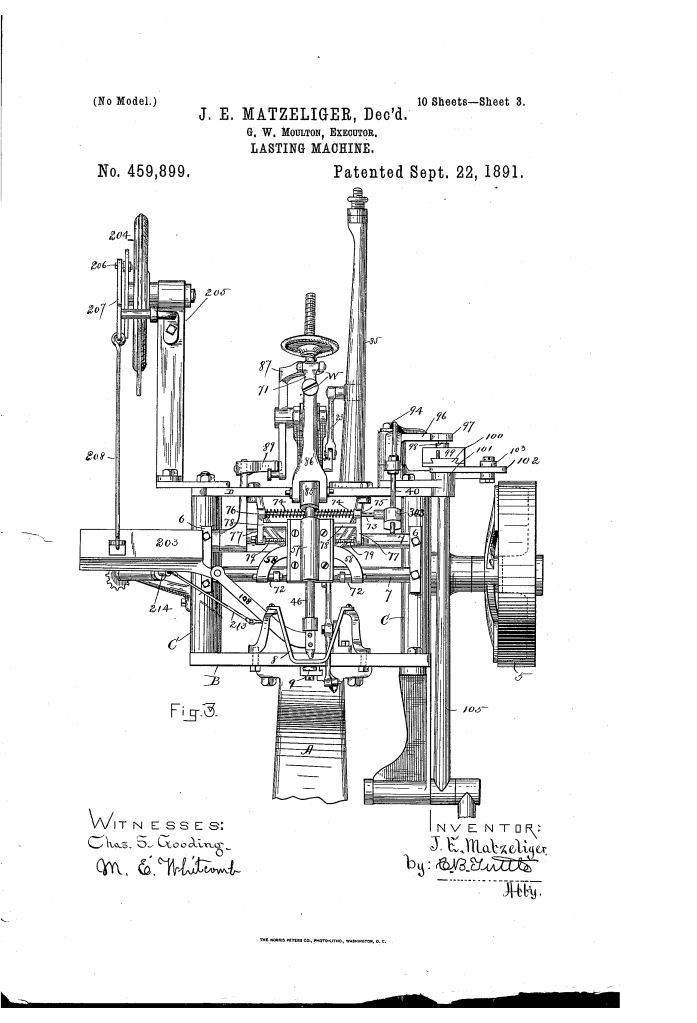

Jan E. Matzeliger’s patent for a “Lasting Machine,” No. 459,899, is a monumental invention in the history of industrial automation. Patented on September 22, 1891, the patent describes a complex, multi-functional machine that automates the process of lasting a shoe. Lasting is the crucial step of stretching the shoe’s upper over the last (a form shaped like a human foot) and securing it to the insole. Before this machine, this was a highly skilled and time-consuming manual task.

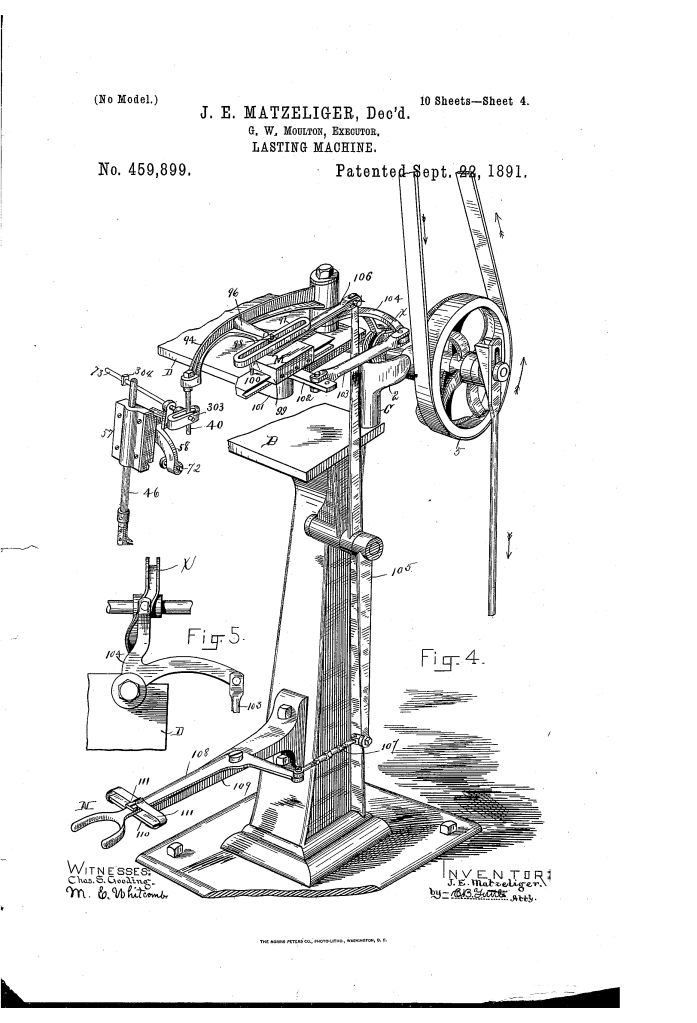

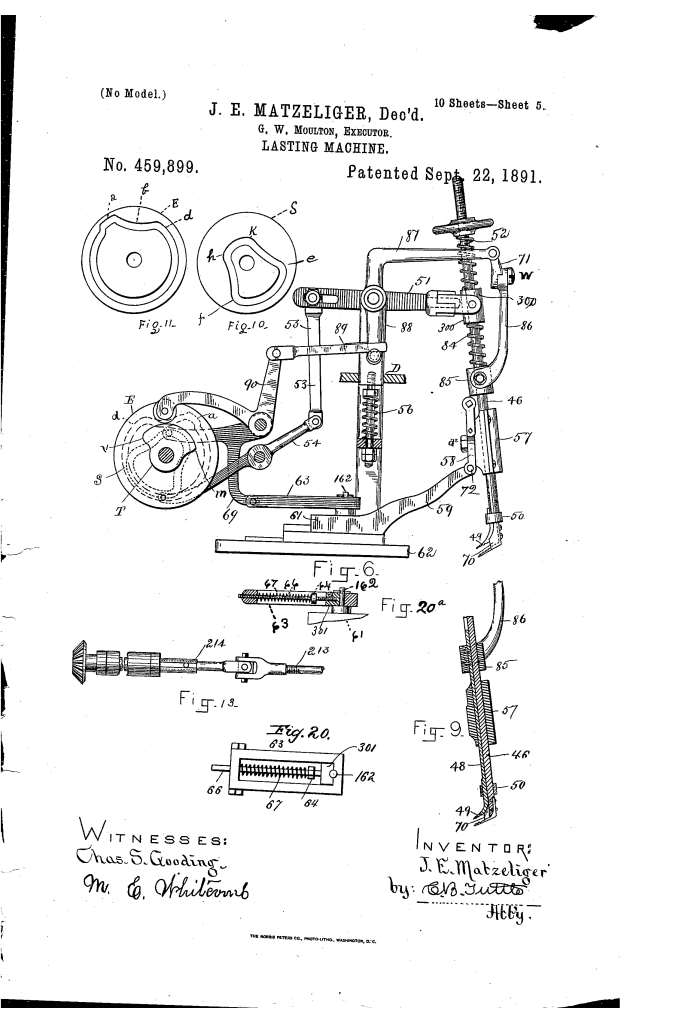

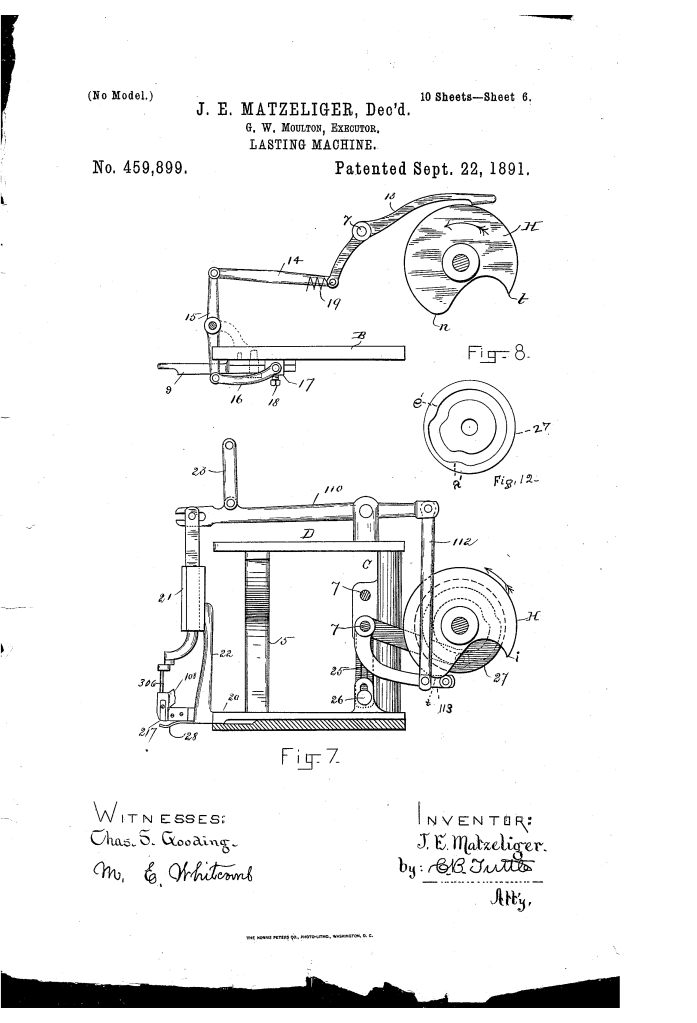

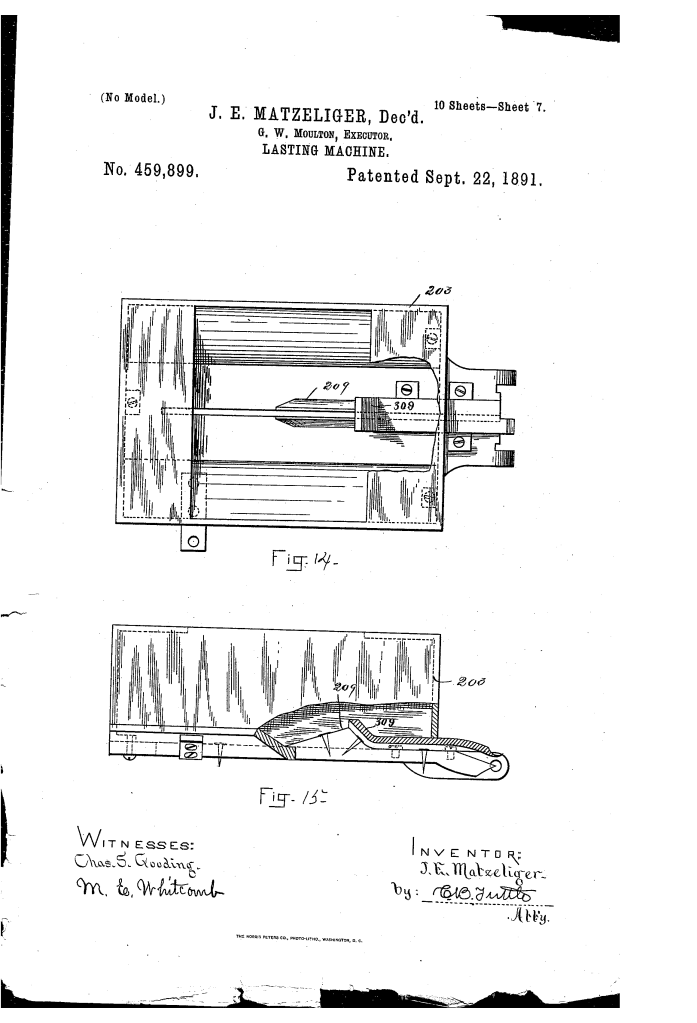

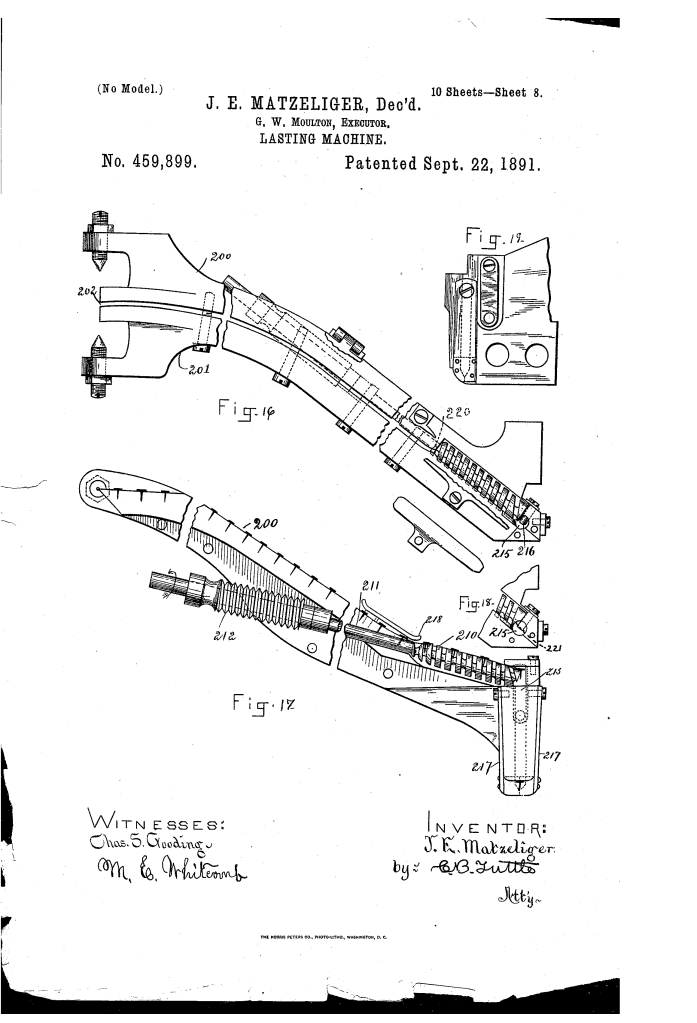

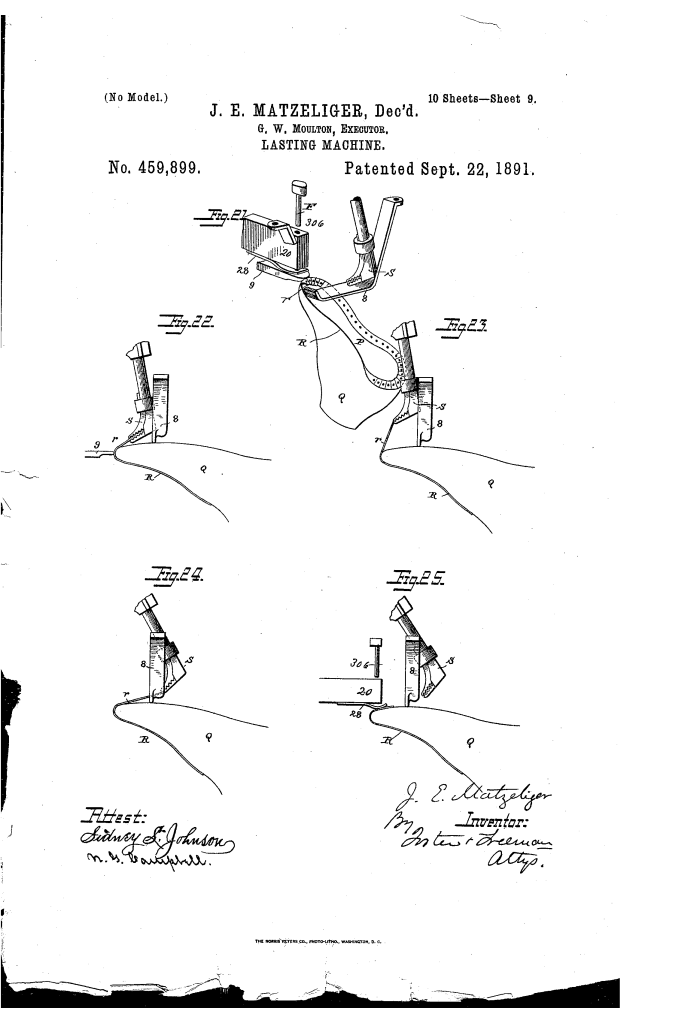

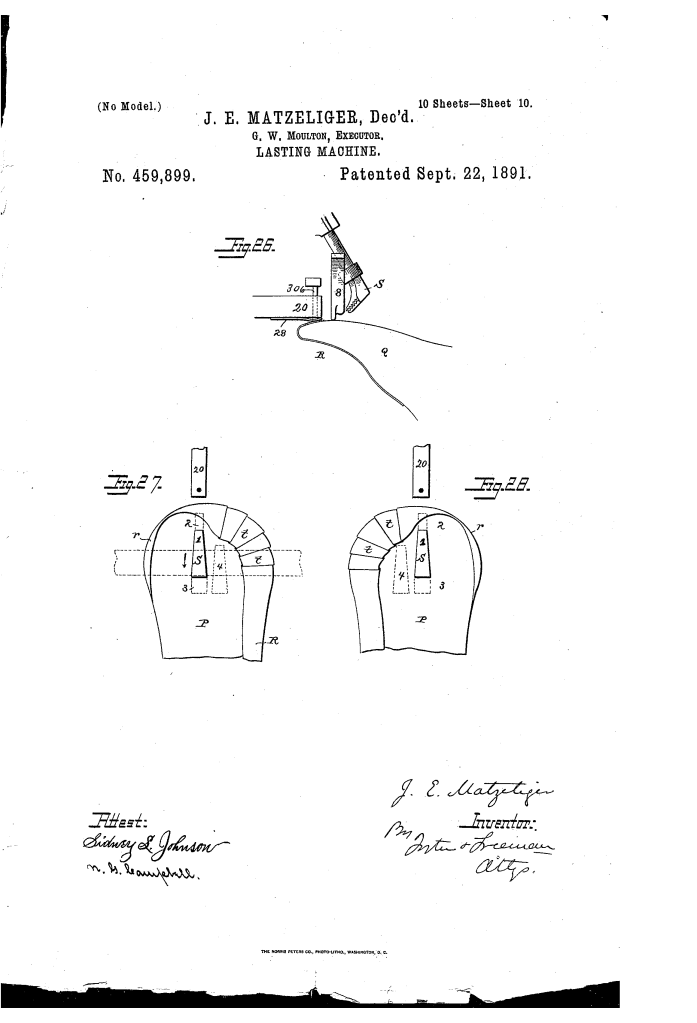

The patent, consisting of 10 sheets of detailed drawings and a lengthy specification, describes an intricate system of levers, springs, cams, and shafts that work in timed coordination. Its key innovations include:

- Automated Grippers (Pinchers): A single pair of mechanical jaws (pinchers) would grip the shoe upper, pull it down over the last, and secure it with a tack. The pinchers could move vertically, forward, backward, and even side-to-side to plait the leather at the corners (the toe and heel).

- Automated Nailing Mechanism: The machine included a tack-separating and distributing mechanism that would feed tacks one at a time to a driver. A spring-powered hammer would then drive the tack into the shoe to hold the upper in place.

- Wiper System: A spring-loaded “wiper” would advance over the shoe, smoothing the leather and holding it tightly against the sole while the tack was inserted.

- Manual Control: Crucially, the machine was designed for a human operator to hold the last. This allowed the operator to “feel” the leather and apply varying degrees of pressure or to make fine adjustments as needed, accommodating different types of leather and shoe designs. The machine also included a shifter that could be operated by the user’s knee to control the lateral “plaiting” motion.

Societal Impact

Matzeliger’s lasting machine was a revolutionary invention that transformed the shoe manufacturing industry and had a profound economic impact.

Economic Transformation

Before Matzeliger’s invention, a skilled hand-laster could produce about 50 shoes a day. Matzeliger’s machine could produce between 150 and 700 shoes per day, a staggering increase in productivity. This innovation drastically reduced the cost of shoes, making them affordable for the masses and fueling the growth of major shoe manufacturing cities like Lynn, Massachusetts.

Industrial Automation

The lasting machine is a landmark in the history of industrial automation. It automated a task that was previously considered impossible for a machine to do, as it required human-like dexterity and judgment. This invention was a key step in the transition from skilled manual labor to factory-based mass production. The patent’s detail on the interplay of complex mechanical components showcases Matzeliger’s engineering genius.

The Inventor’s Legacy

Jan E. Matzeliger was a brilliant and persistent African American inventor born in Suriname. He arrived in the United States and, after working in a shoe factory, dedicated himself to solving the problem of lasting. This patent and his other related inventions were so groundbreaking that his patents were eventually bought by the United Shoe Machinery Company, which became a giant in the industry. Matzeliger’s work is an enduring example of the ingenuity and perseverance of Black innovators who, despite facing immense systemic racism and hardship, made foundational contributions to American industry and technology.