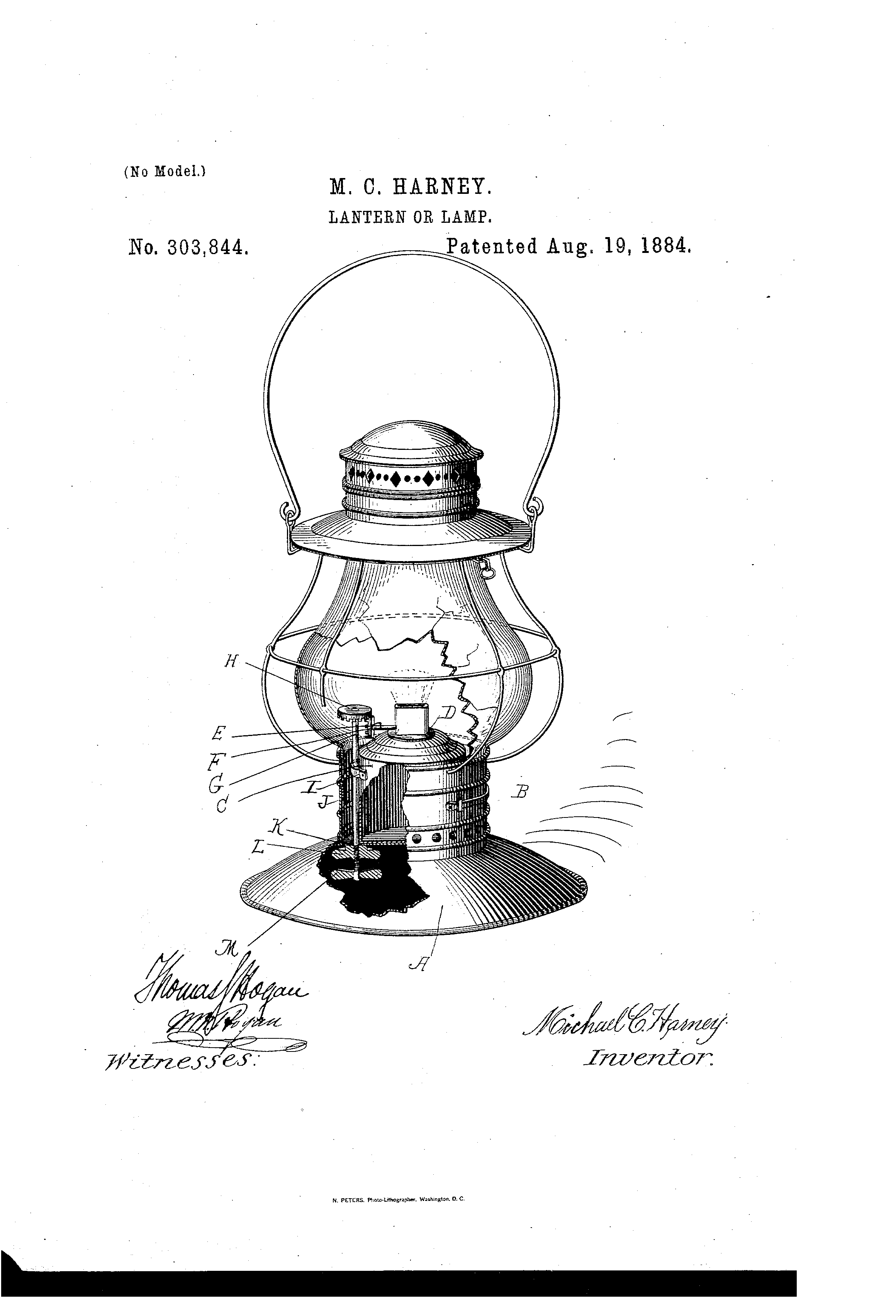

Lantern or Lamp (Michael C. Harney, No. 303,844)

The patent by Michael C. Harney of St. Louis, Missouri, describes an Improvement in Wick-Raisers (Patent No.1 303,844, 1884). The invention focuses on the gearing mechanism used to adjust the wick, aiming to prevent the wick-shaft from being displaced upward during operation, which often caused the burner cone or cap to lift off the lamp.

Inventor Background: Michael C. Harney

Michael C. Harney was an inventor focusing on domestic and utility items. His invention addressed a common flaw in kerosene lamps—a major source of domestic light at the time—where the mechanical operation of the wick often led to structural failure (the burner cap lifting), which was a safety and efficiency concern.

Invention and Mechanism (Simplified)

The device is a geared mechanism with a lock-nut adjustment located below the drive to maintain constant downward pressure on the wick shaft.

- Standard Wick Mechanism: The lamp has a fount (C), a burner (D), and a horizontal wick-shaft (E) which is geared to move the wick up and down. A crown-wheel (F) is attached to the wick-shaft.

- Vertical Drive Shaft ($G’$): A vertical shaft runs from the base to the wick-shaft. It has a crown-wheel (H) at its upper end that meshes with the wick-shaft’s crown-wheel (F). The lower end of this shaft has a regulating wheel (M) for the user to turn.

- The Lock-Nut Adjustment (Key Innovation): The lower end of the vertical shaft ($G’$) is screw-threaded. A lock-nut (L) is placed beneath the floor (K) of the air-chamber (J).

- Function: The lock-nut (L) can be adjusted on the threaded vertical shaft ($G’$) to precisely set the engagement depth between the crown-wheels (H and F).

- Crucial Result: By locating the adjustable nut (L) beneath the floor, the mechanism applies a downward force on the vertical shaft as the nut is tightened. This downward force counteracts the upward thrust generated when the horizontal and vertical crown-wheels engage, thereby holding the wick-shaft (E) securely to its bearings and preventing the displacement of the burner cone or cap.

Concepts Influenced by This Invention

Harney’s wick-raiser influenced subsequent mechanical and geared designs by pioneering the use of load-based adjustment for structural stability.

- Load-Bearing Adjustment (Counter-Thrust): The core concept of placing a threaded fastener (lock-nut L) beneath the structural floor (K) of a geared system to counteract and absorb the separating thrust generated by the meshing gears influenced the design of industrial gearboxes and high-stress rotating mechanisms. This ensures the gear housing remains stable under load.

- Axial Stability in Geared Systems: The method of using a threaded spindle and lock-nut to axially position and stabilize a rotating shaft influenced the engineering of small mechanisms that require precise gear mesh and high reliability (e.g., clockworks, consumer electronics gears).

- Preventing Component Disassembly (Safety): The invention solved a safety flaw (the burner cap lifting) by securing the underlying mechanism, influencing the design philosophy of ensuring critical utility components (like fuel sources) remain structurally sound during operation.