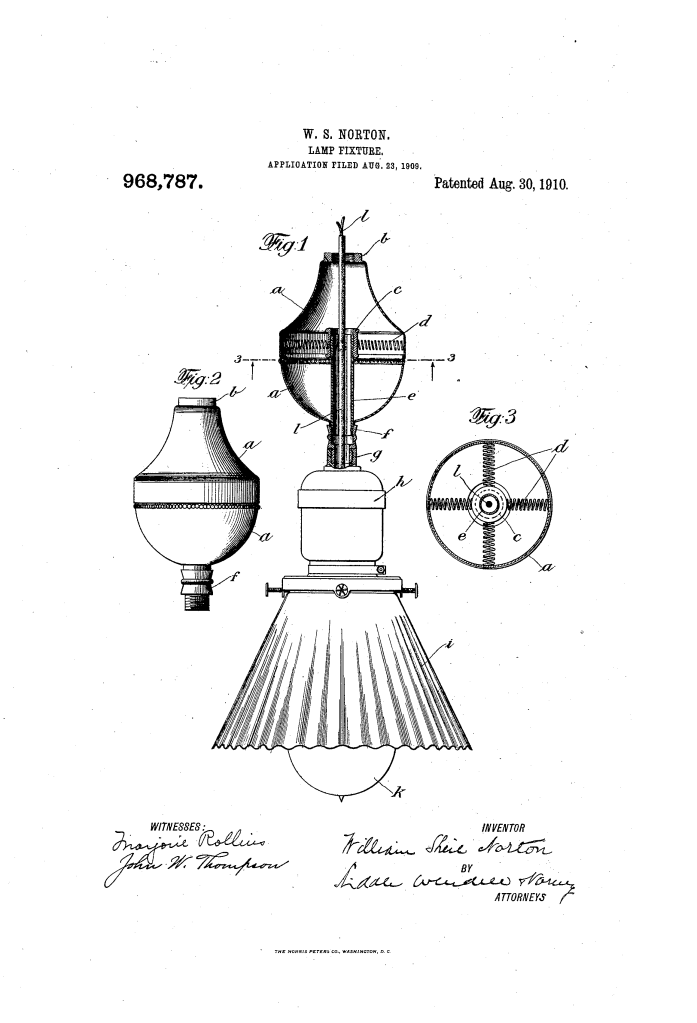

Lamp-Fixture (William Sheil Norton, No. 968,787)

The patent by William Sheil Norton describes a Lamp-Fixture (Patent No. 968,787, 1910). The invention is focused on creating a simple and efficient shock-absorbing device within the fixture itself to protect the filaments of electric lamps, especially sensitive ones like early tungsten lamps, from breakage due to external shocks and jars.

Notably, Norton assigned one-half interest in this patent to Lewis Howard Latimer of Flushing, New York, the renowned African-American inventor and draftsman.

Inventor Background: William Sheil Norton & Lewis H. Latimer

- William Sheil Norton: The primary inventor, residing in New York, focused on mechanical solutions for domestic and industrial applications.

- Lewis Howard Latimer (1848–1928): The co-assignee, Latimer was a crucial African-American inventor, draftsman, and engineer. His expertise in electric lighting (he patented the carbon filament process) made him a natural collaborator or investor in improving the lifespan and efficiency of new lamp technologies like tungsten.

Invention and Mechanism (Simplified)

The fixture utilizes an internal, spring-suspended core that allows the lamp and socket assembly to float, absorbing vertical shocks before they reach the filament.

- Outer Shell ($a$): A two-part enclosing shell forms the fixture’s exterior. It is designed to be fully enclosed to exclude all dust.

- Internal Supporting Member ($e$): A piece of metal tubing ($e$) serves as the longitudinally extending lamp-supporting member. The conducting wires ($l$) pass up through this tube.

- Spring-Suspended Nut ($c$): The upper end of the tube ($e$) engages a nut ($c$). This nut is not fixed to the shell.

- Shock-Absorbing Springs (Key Innovation): A series of spiral springs ($d$) are connected at one end to the internal nut ($c$) and at the other end to the inside of the upper part of the outer shell ($a$).

- Function: This arrangement causes the internal supporting member ($e$) and the nut ($c$) to be resiliently supported and restrained by the springs. The springs extend laterally (horizontally) to the central member.

- Shock Absorption: The entire weight of the lamp, shade, and socket is supported by the tube ($e$), which is allowed to reciprocate freely in a vertical direction.

- Result: Any shocks or jars transmitted through the building or chandelier are absorbed by the springs ($d$) before the excessive movement reaches the delicate tungsten filament ($k$), preventing breakage and extending lamp life.

Concepts Influenced by This Invention

Norton and Latimer’s lamp fixture influenced subsequent designs in lighting and industrial machinery by pioneering integrated, non-destructive shock mounting for sensitive components.

- Integrated Shock Absorption (Filament Protection): The core concept of mounting the entire load assembly (lamp, socket, and shade) on internal, resilient springs within a rigid shell to absorb vertical and lateral shocks influenced the design of fixtures for sensitive equipment long before modern rubber or foam mounts were common.

- Lateral Spring Suspension: The specific technique of using laterally extending spiral springs to restrain and support a central, vertically reciprocating member ($e$) is an efficient way to achieve omni-directional isolation within a small space. This configuration is used in various industrial dampening and vibration isolation mounts.

- Dust and Component Isolation: The dual requirement for shock absorption and full enclosure to exclude dust influenced the design of protected mechanisms where both physical movement and environmental contamination must be managed.

- Extending Tungsten Life: This invention was a direct engineering solution to a major commercial problem (the fragility of early tungsten filaments), contributing to the rapid adoption and commercial viability of high-efficiency incandescent lighting.