Kneading-Machine (Joseph Lee, No. 524,042)

The patent by Joseph Lee of Auburndale, Massachusetts, describes an improved Kneading-Machine for preparing and kneading bread or pastry dough. The object was to provide a machine that would thoroughly mix and knead the dough and bring it to a superior quality condition, significantly reducing the labor and time associated with hand-kneading, making it suitable for hotels or houses requiring large quantities.

Invention and Mechanism

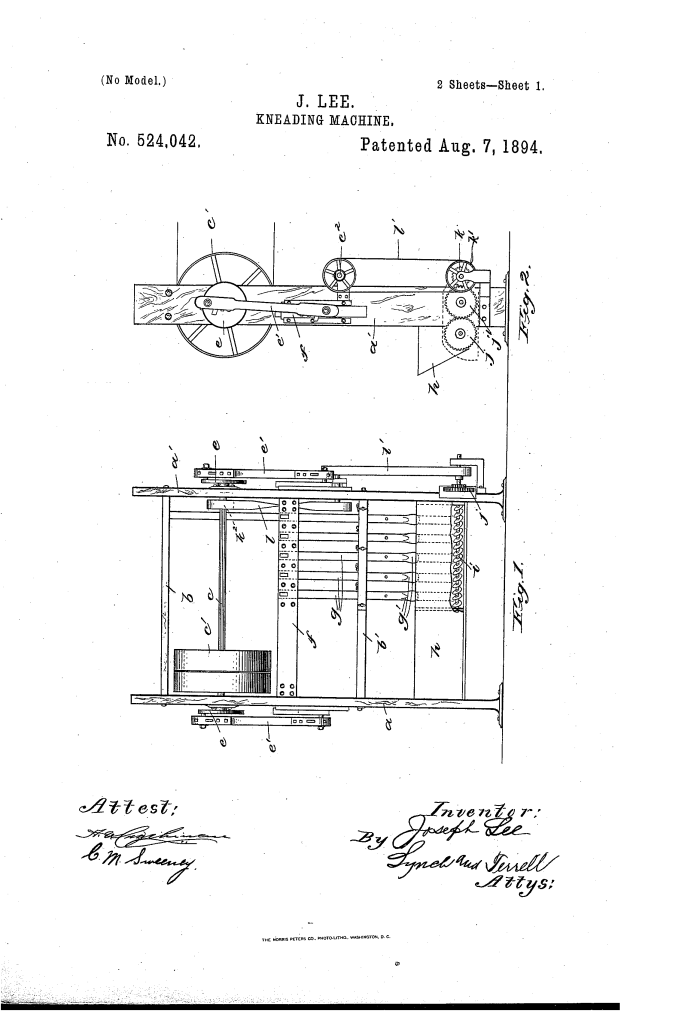

The machine uses a combination of vertically reciprocating pestles for kneading and horizontally rotating screw conveyers for mixing and turning the dough.

- Kneading Mechanism (Vertical Reciprocation):

- Frame: Consists of upright posts (a,a) with cross-beams (b,b).

- Rotary Shaft (c): A horizontal shaft mounted near the top, powered by a driving pulley (c′).

- Reciprocating Head (f): A beam mounted in vertical ways in the uprights (a,a). It is driven by the rotary shaft (c) via cranks (e) and pitmen (e′), converting the rotary motion into vertical reciprocating motion.

- Pestles (g′): Arms secured to the reciprocating head (f). They feature pestles (blunt ends) that are driven with great force into the dough.

- Function: The pestles pound and knead the dough with a powerful vertical action, forcing the dough from the center of the trough to the sides.

- Mixing and Turning Mechanism (Horizontal Rotation):

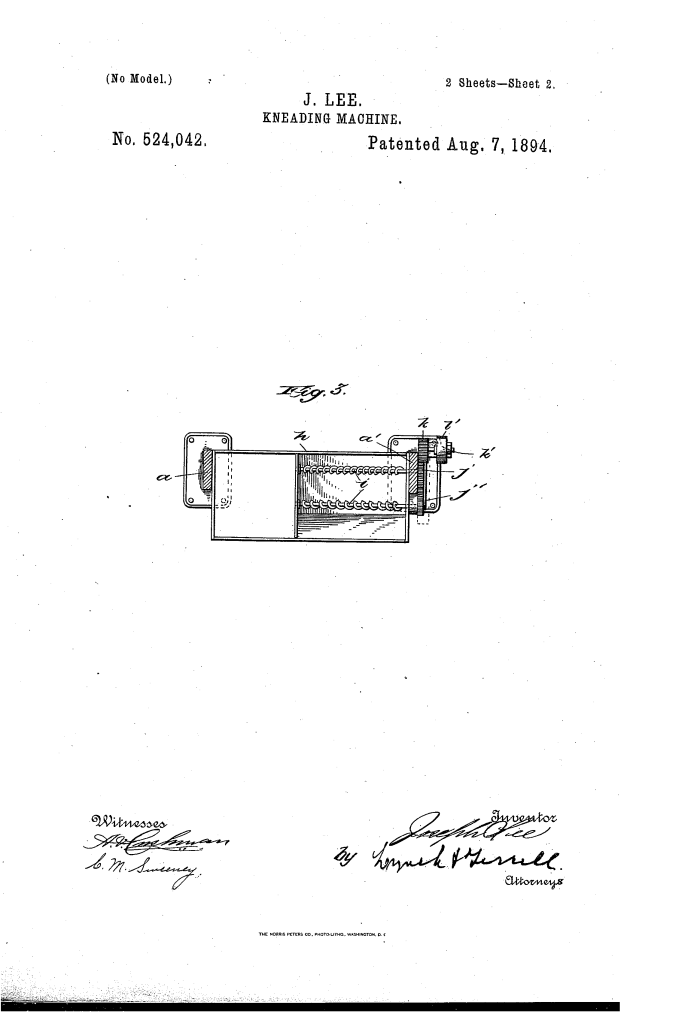

- Dough Trough (h): Mounted in the lower part of the frame, directly beneath the pestles.

- Screw Conveyers (i): Two horizontal screw conveyers placed near the bottom of the trough, on either side of the path of the pestles.

- Drive: The conveyers are driven by a gear train and belts from the main shaft (c) and an intermediate shaft (o′). The gear wheels (j,j) of the conveyers mesh with each other.

- Function: The intermeshing gears ensure the conveyers revolve in opposite directions. As the dough is forced to the sides by the pestles, the conveyers pick it up, carry it forward a short distance, and then throw it back to the center of the trough beneath the pestles.

- Combined Operation:

- The constant action of the pestles and the perpetual turning action of the conveyers ensures the dough is thoroughly mixed and continually subjected to the powerful kneading action without requiring manual intervention, resulting in a product of “superior quality and fineness.”

Historical Significance and the Inventor

Joseph Lee’s 1894 patent is an important development in the history of food processing equipment, specifically addressing the industrialization of baking.

- Shift to Commercial Baking: The late 19th century saw a massive increase in commercial baking to supply growing urban populations, as well as large-scale institutions like hotels. Hand-kneading became impractical and inconsistent. Lee’s machine provided a reliable, mechanical alternative for producing large, uniform batches of dough.

- Dual-Action Design: The invention is significant for its dual-action approach—combining the impact of the pestles (akin to traditional hand-pounding or punching down) with the turning and mixing action of the conveyers (akin to folding the dough). This combination was highly effective for achieving the desired gluten structure and homogeneity in dough.

- The Inventor (Joseph Lee): While the patent does not provide extensive personal details, Joseph Lee’s name is highly significant in baking history. He is recognized as a Black inventor who patented a series of food preparation machines. His most famous invention, patented a few years later, was a machine for making bread crumbs, further cementing his role in automating the commercial baking industry.

Relation to Current Items

Lee’s Kneading-Machine is a direct conceptual ancestor to several modern industrial mixing and processing machines:

- Industrial Kneading Machines: The machine’s core function is performed today by industrial spiral mixers and planetary mixers . These modern machines often replace the vertical pestles with spiral hooks or paddles, but the fundamental principle remains the same: combining a primary kneading motion with a secondary turning/folding action (either by rotating the bowl or using internal mixing arms) to ensure homogeneity.

- Screw Conveyors in Processing: The use of screw conveyers to move, mix, and reintroduce material is a standard design in countless industrial processes, especially in the handling of viscous or semi-solid materials like dough, concrete, and plastics.

- Reciprocating Motion: The use of a crank and pitman to convert rotary power into powerful, slow reciprocating motion is a classic mechanical solution still employed in various industrial piston pumps, presses, and heavy-duty stamping machines where high linear force is required.