Interliner (David Baker, No. 1,620,064)

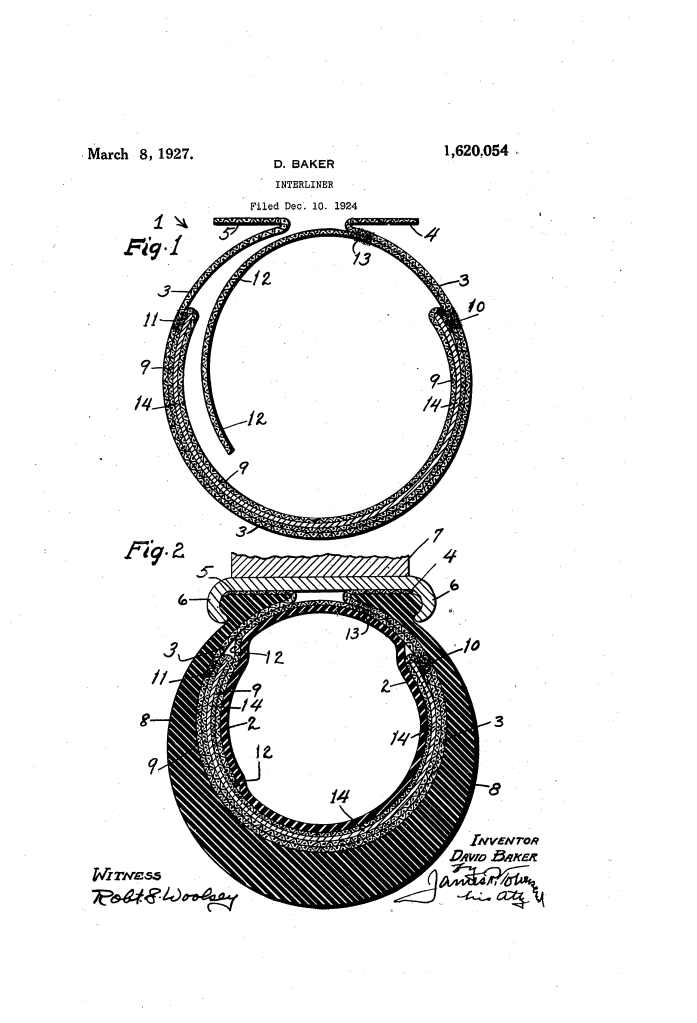

The patent by David Baker of Los Angeles, California, describes a protective Interliner for pneumatic tires (Patent No. 1,620,064, 1927). This invention is a specialized internal sleeve designed to provide a “fail-safe” layer between a tire’s inner tube and its outer casing. Baker’s primary objective was twofold: to protect the delicate inner tube from radial punctures and to prevent the tube from “creeping” or shifting within the tire—a common cause of valve stem failure and internal friction wear. His innovation utilizes a nested canvas construction with integrated telescoping metal armor.

Inventor Background: David Baker

David Baker was an African American inventor and engineer active in the booming automotive landscape of Southern California during the late 1920s. As vehicle speeds increased and roads remained often littered with debris, “flat tires” were a constant threat to motorists. Baker’s 1927 patent demonstrates a sophisticated approach to structural reinforcement and material science, using heavy-duty textiles and resilient metal segments to create a protective barrier. His work is a classic example of early automotive safety engineering, focusing on extending the lifespan of expensive tire components.

Key Mechanical & Structural Systems

The interliner acts as a secondary “skin” that completely envelopes the inner tube.

1. The Annular Canvas Casing (3, 4, 5)

- Material: The main body (3) is constructed of heavy, fibrous canvas.

- Flange Anchor (4, 5): The inner periphery of the casing terminates in two annular flanges that extend in opposite directions.

- Function: These flanges are clamped between the tire rim (6) and the inner edge of the tire (8). Once the tube is inflated, the air pressure locks these flanges in place, preventing the interliner and the inner tube from “creeping” relative to the wheel.

2. The Multi-Layered Pocket and Flap (9, 12)

- Folded Pocket (9): An inner canvas layer is stitched to the main casing at points 10 and 11, creating a dedicated annular pocket.

- The Flap (12): A loose canvas flap is stitched at point 13 to cover the inner periphery of the tube.

- Function: This internal architecture creates a reinforced zone specifically at the “tread portion”—the area most vulnerable to road debris—while the flap ensures the tube is fully enclosed and protected from the metal rim itself.

3. Telescoping Tread Armor (14) (Key Innovation)

- The Armor: Inside the canvas pocket is a resilient tread guard (14) made of metal segments.

- Telescoping Ends: The metal segments are designed with overlapping, telescoping ends.

- Function: This allows the armor to expand and contract. As the tire is inflated or experiences an impact, the armor segments slide against one another to compensate for the change in volume and to absorb the energy of an impact without puncturing the tube.

Improvements Over Standard 1920s Tires

| Feature | Standard Inner Tubes | Baker’s Interliner System |

| Puncture Resistance | Vulnerable to nails, glass, and sharp rocks. | Resilient metal armor (14) blocks radial punctures. |

| Tube Stability | Tubes often “crept,” tearing the valve stem. | Annular flanges (4, 5) lock the assembly to the rim. |

| Structural Integrity | High pressure could cause tube blowouts. | Heavy canvas casing (3) reinforces the entire tube surface. |

| Adaptability | Rigid guards could snap or restrict inflation. | Telescoping design allows for variable air pressure. |

Significance to Engineering and Road Safety

David Baker’s interliner influenced the development of reinforced tires and puncture-proof technology.

- Kinetic Impact Absorption: The telescoping armor principle—allowing rigid segments to move relative to one another to absorb shock—is a foundational concept in dynamic protection systems used in armored vehicles today.

- Integrated Friction Management: By solving the problem of “creeping,” Baker anticipated modern bead-lock technology and high-performance tire liners that ensure the tire and wheel move as a single unit.

- Modular Safety Layers: The logic of an “interliner” (a layer between the pressure vessel and the outer shell) is still reflected in aerospace fuel tank design and modern multi-ply tire construction.

- Material Synergy: Combining the flexibility of canvas with the rigidity of metal demonstrated an early mastery of composite engineering, utilizing each material for its specific mechanical advantage.