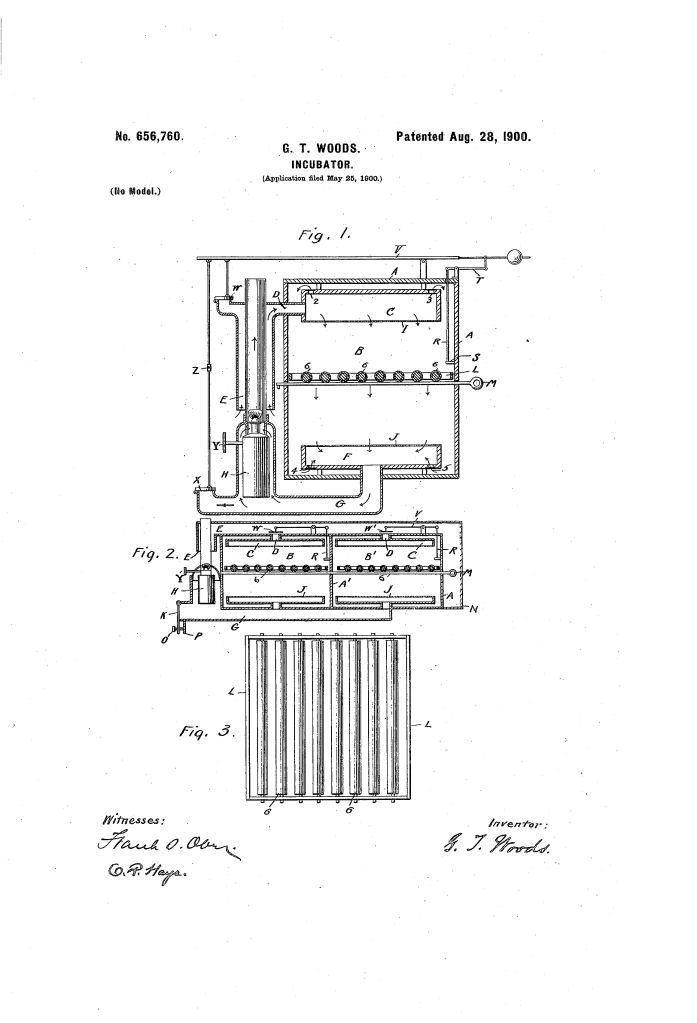

Incubator (Granville T. Woods, No. 656,760)

The patent by Granville T. Woods of New York, N.Y., describes certain new and useful Improvements in Incubators or Egg-Hatching Machines (Patent No. 656,760, 1900). The primary objects are to achieve precise ventilation (maintaining air humidity similar to the outside atmosphere), maintain a practically even temperature throughout the entire hatching chamber, and ensure the heated air has a slow, positive downward movement toward the eggs.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910) was an incredibly prolific and important African-American inventor known as the “Black Edison,” with over 50 patents primarily in electrical and mechanical systems. This patent demonstrates his application of engineering principles—particularly fluid dynamics and automatic control—to a biological and agricultural problem: creating a stable, high-efficiency environment for hatching eggs.

Invention and Mechanism (Simplified)

The incubator is an airtight, multi-chambered system that uses controlled air pressure, porous barriers, and differential valve control to maintain precise thermal and humidity stability.

1. Airflow and Ventilation (Key Innovation)

- Airtight Walls: The entire walls of the main hatching-chamber (B) are made of material impermeable to air or gas.

- Porous Diaphragms (I, J, 2, 3, 4, 5): The air movement into and out of the chamber is controlled by large and small porous diaphragms (like cotton cloth) that have minute apertures.

- Slow, Downward Flow:

- Inlet Chamber (C): Arranged near the top, receiving heated air (E).

- Exhaust Chamber (F): Arranged near the bottom, connected via a duct (G) to the flame of the heater (H).

- Function: The heater flame draws air from the exhaust chamber (F), creating a positive, slow downward draft through the hatching chamber. The porous diaphragms ensure the air is delivered slowly and evenly (diffused minute quantities), preventing drafts and maintaining the natural humidity.

2. Automatic Temperature Regulation (Differential Valves)

- Thermostat (R): Secured to the side wall, connected to levers (T, V).

- Dual Valves (W, X): The lever system controls two valves, W and X.

- Valve W: Controls the main heated air supply.

- Valve X: Controls a direct air-supply pipe to the heater flame, bypassing the system.

- Differential Action: The linkage (link Z) has slack or lost motion purposefully built in.

- Rising Temperature: The thermostat first opens valve W. If the temperature still rises, the slack is taken up, and the slightest further expansion opens valve X. This dumps cold air onto the flame, temporarily slowing the heating process and stabilizing the temperature.

- Steady State: Valve X may be intentionally held open to admit outside air directly to the flame, ensuring the heater draws only the natural amount of air from the hatching chamber, maintaining the desired slow flow.

3. Uniform Heat Distribution

- Small Chambers, Single Source (Adaptability): The system is designed to allow a single heat source to supply a plurality of small hatching chambers ($B’, B”$), with each chamber having an independent thermostat. This is more economical than using many small heaters.

Concepts Influenced by This Invention

Woods’s incubator influenced subsequent systems by pioneering the precise control of internal environment using porous media and differential mechanical actuation.

- Controlled Diffusion/Slow Flow Ventilation: The core concept of using multiple, minutely-apertured porous diaphragms to control the speed and evenness (diffusion) of air movement influenced the design of modern cleanrooms, biological chambers, and specialized HVAC systems that require laminar (slow, smooth) airflow without disruptive currents.

- Differential Actuation for Control: The complex linkage using lost motion (link Z) to sequence the operation of two separate control valves (W and X) influenced the design of multi-stage mechanical controllers and safety systems. This allows for fine-tuning the response: a gentle adjustment (W) followed by a strong emergency correction (X).

- Integrated Environmental Regulation: The design’s successful integration of air circulation, humidity control (via porous material), and temperature regulation (via dual valves) into a single, closed system influenced the engineering of all modern environmental chambers and controlled growth environments .

- Energy-Efficient Zoned Heating: The system’s application to multiple small chambers from a single source is an early example of efficient zoned heating, maximizing fuel economy for high-volume operations.