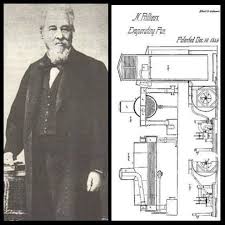

Norbert Rillieux (1806-1894) was a groundbreaking African-American engineer and inventor who revolutionized the sugar industry with his multiple-effect evaporator under vacuum, which was a significant “Improvement in Sugar Works.” His invention was a major milestone in chemical engineering and is considered the foundation of all modern industrial evaporation.

Rillieux received his most important patent for this invention, U.S. Patent No. 4,879, on December 10, 1846, titled “Improvement in Sugar-Making.” He also received an earlier patent in 1843 (U.S. Patent No. 3,237) for a double-effect evaporator, which was superseded by his more comprehensive 1846 patent.

How Norbert Rillieux’s Multiple-Effect Evaporator Worked:

Before Rillieux, the common method for concentrating sugarcane juice into sugar crystals was the “Jamaica Train” or “Sugar Train.” This involved boiling sugar cane juice in a series of open kettles, with enslaved laborers manually ladling the boiling, thickening syrup from one kettle to another of decreasing size. This process was:

- Dangerous: Workers faced extreme heat and the risk of severe burns.

- Inefficient: A lot of sugar was lost due to scorching, spillage, and inconsistent heat control.

- Costly: It required enormous amounts of fuel and labor.

Rillieux’s genius lay in applying his understanding of thermodynamics and latent heat to create a far more efficient and safer system. His multiple-effect evaporator consisted of a series of closed vacuum pans (usually three or more) connected in sequence:

- Reduced Pressure (Vacuum): Each pan in the series operated at a progressively lower pressure (a partial vacuum). Lowering the pressure above a liquid significantly reduces its boiling point.

- Sequential Evaporation:

- The first pan received the fresh sugarcane juice and was heated by an external steam source (from a boiler). The juice would boil at a relatively low temperature due to the vacuum.

- As the juice boiled, it produced steam (water vapor). Instead of releasing this steam into the atmosphere (as in the Jamaica Train), Rillieux captured it.

- This captured steam was then used as the heat source for the next pan in the series. Because the second pan was at an even lower pressure, the steam from the first pan (even at its slightly reduced temperature) was still hot enough to boil the juice in the second pan.

- This process continued down the series, with the steam from one pan heating the next. Only the first pan required an external heat source; subsequent pans were heated by the latent heat recovered from the steam of the preceding pan.

- Condensation: The steam from the final pan in the series would be condensed back into water, often by a condenser, and could potentially be reused in the boiler.

Impact and Significance of Rillieux’s Invention:

- Revolutionized the Sugar Industry: Rillieux’s evaporator made sugar production safer, vastly more efficient, and significantly cheaper.

- Safety: Eliminated the dangerous manual transfer of boiling liquids.

- Efficiency: Drastically reduced fuel consumption because the same steam was used multiple times, and the lower boiling temperatures prevented scorching.

- Quality: Produced a higher quality, whiter, and more uniform crystallized sugar, turning sugar from a luxury item into an accessible staple.

- Labor Savings: Greatly reduced the manual labor required, which was particularly significant in an industry heavily reliant on enslaved labor in the American South.

- Foundation of Chemical Engineering: Rillieux’s invention is recognized as one of the earliest and most profound applications of modern chemical engineering principles, particularly regarding heat recovery and vacuum evaporation.

- Wider Applications: The fundamental principles of his multiple-effect evaporator are still used today in numerous industries for concentrating liquids and recovering waste liquids, including the production of:

- Condensed milk

- Soap

- Gelatin

- Glue

- Salt

- Distilled water

- In the chemical and pharmaceutical industries.

- Personal Achievement: As a free man of color educated in France, Rillieux’s success in the pre-Civil War American South was an extraordinary testament to his intellect and perseverance in the face of widespread racism.

Norbert Rillieux’s “Improvement in Sugar-Making” fundamentally transformed an entire industry and laid the groundwork for industrial evaporation processes used globally to this day, solidifying his place as a pivotal figure in the history of invention and chemical engineering.