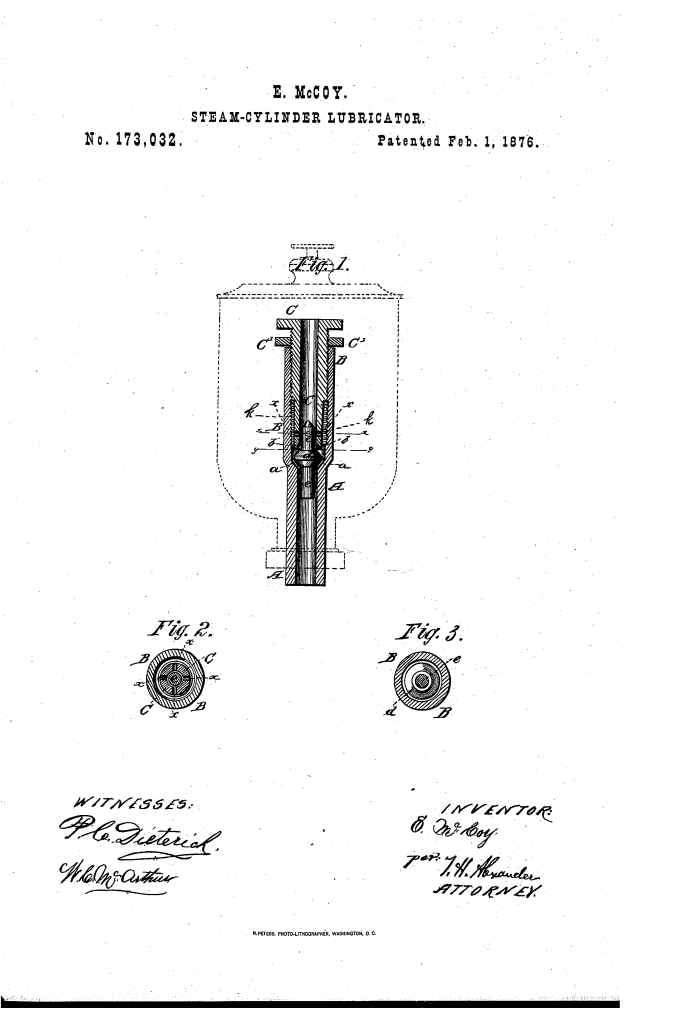

Improvement in Steam-Cylinder Lubricators (Elijah McCoy, No. 173,032)

The patent by Elijah McCoy of Ionia, Michigan, describes an Improvement in Steam-Cylinder Lubricators (Patent No. 173,032, 1876). The invention relates to the class of lubricators where steam passes up through a central tube in the oil cup, and the lubricating oil flows downward through the same tube. The primary object is to improve the construction of this central tube with a regulator and an interior valve to ensure that only oil, and not condensed water, reaches the steam cylinder.

Invention and Mechanism

The lubricator is a sight-feed system integrated into a central tube, designed to feed pure oil directly onto the valve seat, bypassing water condensation.

- Central Tube and Steam Connection:

- Central Tube (A): The main tube located within the usual oil-cup (not fully shown). Its lower end communicates with the interior of the steam chest.

- Enlarged Portion (B): The upper portion of the tube A is enlarged, forming an interior valve-seat (

).

- The Regulator and Oil Feed (Key Innovation):

- Regulating-Tube (C): A tube screwed into the upper end of the enlarged portion (B). It has a jam-nut (

) to hold it at a desired height (adjusting the overall height of the central tube).

- Open from Top to Bottom: The regulating-tube (C) is hollow from top to bottom.

- Oil Chamber (): The lower portion of the tube C is reduced in diameter, forming an oil-chamber (

) between it and the tube B.

- Perforations (): Small perforations are located in the sides of the regulating-tube (C) near its bottom.

- Function: Oil is poured directly into the top of the regulating-tube (C), where it flows down and is fed directly onto the valve (d). McCoy explicitly states that because the oil is fed from the top, it avoids the problem in prior devices where water (from condensed steam) would collect below and stop the oil flow when the water reached the oil-admission perforations.

- Regulating-Tube (C): A tube screwed into the upper end of the enlarged portion (B). It has a jam-nut (

- The Double Valve:

- Double Valve (): A valve with a stem (

) that works within the space between two valve-seats: the enlarged tube’s seat (

) and the bottom of the regulating-tube’s seat (

).

- Function: The valve controls the flow of oil. Its normal position is closed (due to steam pressure below) and is opened by the upward pressure of the oil column above.

- Double Valve (): A valve with a stem (

- Operation Principle:

- Steam from the chest enters the lower end of the central tube (A).

- As the steam condenses, the resulting water is heavier than oil and settles at the bottom of the oil reservoir (not shown) and the central tube.

- The pressure of the oil fed from the top of tube C forces the double valve (

) open, allowing a small, measured amount of oil to drop down into the steam chest, where it is atomized and carried to the cylinder walls.

Historical Significance and the Inventor

Elijah McCoy’s 1876 patent is fundamental to the history of industrial lubrication and machine efficiency.

- The Inventor (Elijah McCoy): Elijah McCoy (1844–1929) was an exceptionally prolific African-American inventor who held over 57 patents, primarily related to lubrication and railway technologies. He is the original source of the phrase “the real McCoy,” which is commonly believed to have been used by engineers to demand his superior, patented lubricators over inferior imitation products.

- Solving the Industrial Bottleneck: In the era of steam power, stopping machinery to manually lubricate steam-engine cylinders and bearings was a constant necessity, leading to significant downtime and inefficiency. McCoy’s automatic lubricators (starting with his first in 1872) solved this problem by providing continuous, automated lubrication while the machinery was running.

- Refining Lubrication: This specific patent addressed the issue of contamination (water replacing oil) in early sight-feed lubricators. By designing the regulating tube (C) to feed oil directly over the valve, McCoy ensured the consistency and purity of the lubricant reaching the engine, making the machine more reliable.

Core Concepts Utilized Today

McCoy’s principles of controlled, automatic lubrication are essential to modern industrial machinery.

- Sight-Feed Lubrication: The fundamental concept of using a regulated valve and gravity-feed system to introduce oil into a high-pressure environment is the basis for all modern sight-feed oilers and constant-level lubricators , which are common on industrial pumps, motors, and gearboxes.

- Thermal Displacement (Condensation Lubricators): Although electric motors replaced steam, the principle of using thermal displacement (or condensation) to drive the lubrication cycle is still used in systems where lubricant must be introduced into a pressurized line.

- Baffle/Segregation Design: McCoy’s design to segregate the oil supply from the contaminated water condensation (by feeding oil from the top of tube C) is a core principle in modern oil reservoir design, where sumps, baffles, and internal channels are used to separate and prevent water or other contaminants from reaching the pump intake.