The Invention: Portable and Adjustable Plastering-Scaffold

Henry Pickett’s invention relates to a new design for a portable and adjustable scaffold intended primarily for use by plasterers and carpenters.

Key Components and Design Features:

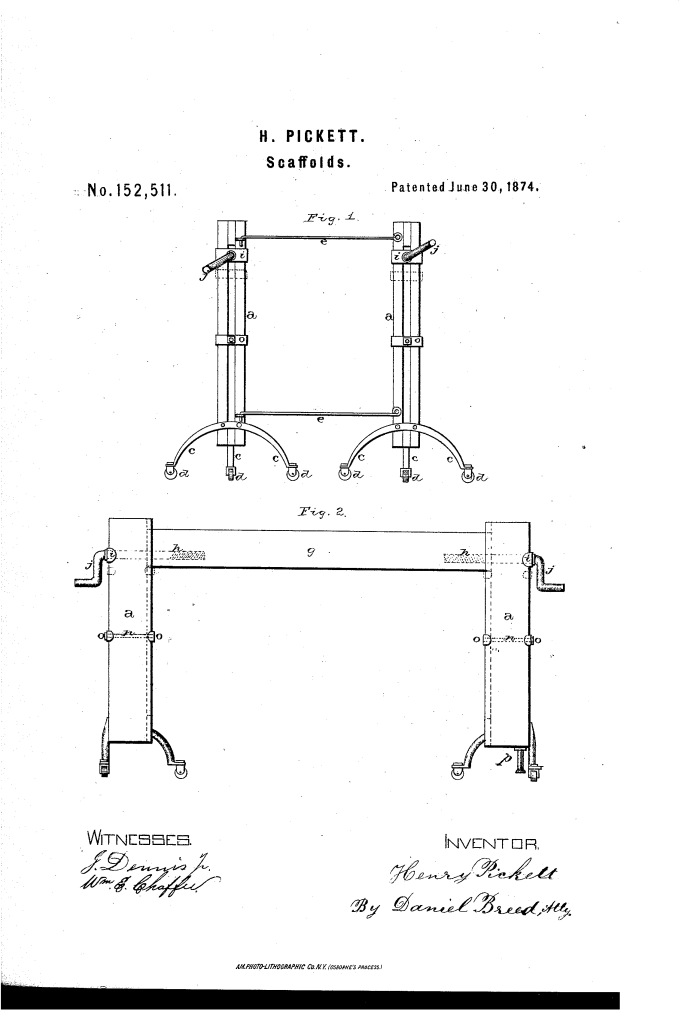

- Posts (a): A number of vertical posts, each slotted nearly its entire length. They can be made in sections connected by hinges or other means to adjust their total height for low or high ceilings.

- Mobility: Each post is supported by a tripod-shaped arrangement of legs (c), and each leg is fitted with a caster (d), allowing the scaffold to be readily moved about the room.

- Bracing (e): Braces extend from post to post at the ends of the frame to keep the scaffold’s width uniform and securely braced.

- Adjustable Beams (g): A horizontal beam connects each pair of posts. The beams are guided by grooves on the inner sides of the posts and can be adjusted freely up and down to regulate the scaffold’s height.

- Clamping/Securing Mechanism:

- Screw-bolts (h): These bolts pass through clamping-plates and the slots in the posts into the ends of the beams (g). They are fitted with hand-cranks (j), allowing the workmen to quickly and easily loosen and fasten the beams at the desired height.

- Clamping-plates (o) and Tightening-bolt (n): These plates clasp the inner and outer edges of each post. They can be moved up to rest directly under the horizontal beams (g) and then secured in position using the tightening-bolt (n). This feature provides an extra safeguard, ensuring the beams will not give way under the weight of the workmen and materials.

- Safe-Lock (p): A pin or “safe-lock” is included, along with a suitable connecting-piece, to attach the scaffold to the floor or another fixture. This prevents any movement of the scaffold while workmen are actively engaged or climbing up or down.

Claims:

Pickett claimed the following combinations as his invention:

- The combination of the screw-bolts (h and n), the plates (o), and the beams (g).

- The combination of the slotted posts (a), the braces (e), the beams (g), the bolts (h and n), and the plates (o).

Historical Significance and Relation to Modern Products

Historical Significance

This 1874 patent represents an early, important step in developing portable, adjustable interior scaffolding specifically for finishing trades like plastering.

- Efficiency in Construction: Before such portable designs, interior scaffolding was often built using heavy, fixed wooden poles and planks, which were time-consuming and expensive to erect, modify, and dismantle. Pickett’s design offered a “cheap, portable, and adjustable” solution, significantly improving efficiency for jobs requiring work at different heights (like high ceilings or cornices).

- Safety Improvements: The dual-locking mechanism, involving both the primary screw-bolts (h) and the secondary supporting clamping-plates (o), demonstrated an early emphasis on redundant safety features. The inclusion of a pin/safe-lock (p) to secure the scaffold against the floor addressed the critical issue of scaffold movement or tipping—a major safety concern in construction work.

- Modular Design: The concept of sectional posts that could be hinged or connected was a foundational idea in modular construction, allowing the same set of equipment to be adapted to different job requirements (i.e., varying ceiling heights).

Relation to Modern Products

Henry Pickett’s fundamental concepts are directly mirrored in modern adjustable scaffolding and work platforms used today:

- Rolling Scaffolds (Mobile Towers): The casters (d) on the tripod base (c) are the direct precursor to the ubiquitous mobile scaffolding tower used indoors by tradespeople (painters, drywallers, electricians) today. Modern rolling scaffolds are essentially enhanced versions of this design, featuring guardrails and locking wheels, but retaining the core idea of easy mobility.

- Adjustable Height Mechanisms: The use of slotted posts (a) and horizontal beams (g) secured by bolts at varying heights is the basis for nearly all non-hydraulic adjustable scaffolding, sawhorse brackets, and Baker-style scaffolding. While modern systems often use quick-release pins (like spring-loaded pins or gravity locks) instead of hand-cranked screw-bolts, the principle of vertical adjustment along slotted uprights is identical.

- Locking and Safety Bracing: The function of the braces (e) and the floor safe-lock (p) is carried forward by modern scaffolding requirements, which mandate cross-bracing for structural integrity and locking casters (often secured via a foot pedal) to prevent movement while the scaffold is occupied. The idea of securing the platform from below (via plates o) is analogous to modern lock-down mechanisms that ensure the platform cannot slip from its support frame.