Improvement in Processes of Treating Cocoa-Nut (Alexander P. Ashbourne, No. 194,287)

The patent by Alexander P. Ashbourne of Oakland, California, describes a novel Process for Treating Cocoa-Nut (Patent No. 194,287, 1877). The invention’s object is to treat both the coconut meat and the extracted oil to enhance preservation, flavor, and color.

Invention and Mechanism

The invention details a multi-step chemical and thermal process applied to the coconut meat to remove a portion of the oil and cure the remainder for preservation.

1. Treatment of Cocoa-Nut Meat

The process consists of the following steps, which render the meat suitable for long-term packing:

- Preparation: Take the raw nuts, pare (peel), and grate or pulverize the meat.

- Steaming: Pass the meat through screens/sieves and steam it for one hour.

- Partial Oil Extraction: Add one gallon of boiling water to one hundred pounds of meat. The heat extracts about one-third of the oil.

- Pressing: Press the meat until it is perfectly dry.

- Curing: Cure the pressed meat by mixing in a preserving agent: one pound of sugar and the white of one egg (albumen), dried and ground, for every three pounds of meat.

- Drying: Place the mass in a drying-machine and slowly dry it for eight hours.

- Result: By removing a portion of the oil (the substance liable to rancidity) and curing the meat with sugar and albumen, the product retains its flavor and sweetness and gains preservative qualities.

2. Treatment of Extracted Oil (Described, but not Claimed)

Note: The inventor states that the oil treatment process is intended for a separate patent application, but describes the steps for context.

- The extracted oil is mixed with boiling water, skimmed, and strained to separate oil from water.

- The hot oil is boiled down for three hours to sink “filthy matters or mother—the substance liable to rancidity—to the bottom.”

- The pure oil is skimmed, placed in a hot kettle, and cured by adding egg whites/shells, alum, and white sugar.

- This mixture is boiled over a slow fire for five hours.

- Result: The oil becomes “fine, clear, and perfectly white,” highly refined, and is claimed to be applicable for toilet, medical, and domestic purposes.

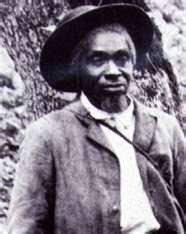

Historical Significance and the Inventor

- The Inventor (Alexander P. Ashbourne): This is the second of two known U.S. patents granted to Alexander P. Ashbourne, an African-American inventor from Oakland, California. His patents, which focus on improving food preparation tools (Biscuit-Cutter) and food processing (Coconut Treatment), highlight his ingenuity in both domestic utility and industrial-scale food manufacturing during the post-Civil War era.

- Preservation Technology: The invention is significant in the history of food preservation. Coconut oil and meat were highly valuable commodities, but their tendency to go rancid (a chemical breakdown that occurs faster with higher oil content) limited their transport and storage life. Ashbourne’s process of removing the most unstable components (some oil) and chemically curing the meat addressed a critical commercial problem.

- Use of Albumen: The use of egg albumen (white) and sugar as a curing agent is notable. Albumen acts as a stabilizer and emulsifier, while sugar acts as a well-known preservative and flavor enhancer. This shows an early understanding of food chemistry applied to commercial processing.

Core Concepts Utilized Today

The process employs fundamental techniques still critical in modern food science and commodity processing.

- Defatting for Preservation: The principle of extracting oil (the rancidity agent) to prolong the shelf life and improve the stability of a natural food product (the coconut meat) is a basic technique in modern food preservation, especially for nuts and grains.

- Refinement via Boiling/Skimming: The process of boiling, skimming, and separating oil to remove impurities (often called degumming or neutralization) is a standard initial step in the modern refining of edible oils

, such as palm, soy, and coconut oils, ensuring a clear, stable product.

- Hydrocolloid Stabilization: The addition of egg albumen (protein) is a form of hydrocolloid stabilization. Albumen acts as a natural binder and barrier. Today, food processing relies heavily on natural hydrocolloids (like gums, starches, and other proteins) to stabilize flavors, bind moisture, and prevent product degradation during storage.