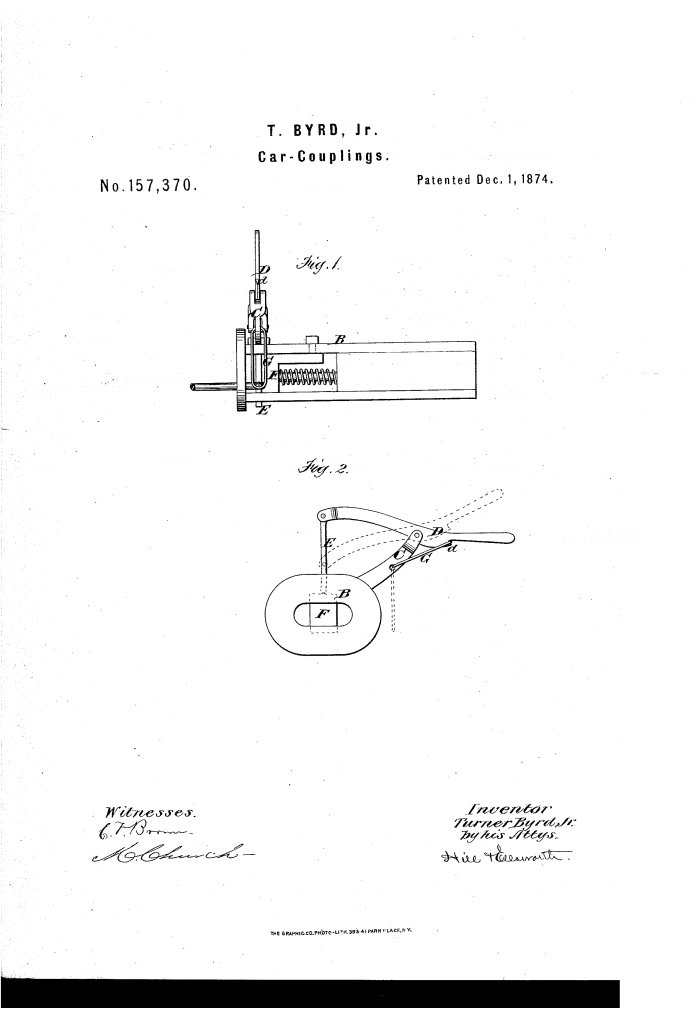

Car-Couplings (Turner Byrd, Jr., No. 157,370)

The patent by Turner Byrd, Jr., of Williamsville, Michigan, describes an improvement to automatic car-couplings (specifically the link-and-pin type) that allows for uncoupling without the operator going between the cars and provides a mechanism to hold the coupling system in an inoperative, elevated position.

Invention and Mechanism

The invention is a simple external lever and lock mechanism applied to a standard automatic link-and-pin draw-head.

- Standard Automatic Coupling: The device is built upon a common draw-head (B) that uses a sliding block (F). When a link from an approaching car enters, it pushes the block (F) backward, releasing the coupling-pin (E), which then drops through the link to effect the automatic coupling.

- Uncoupling Lever (D):

- An arm (C) is rigidly secured to the top of the draw-head (B), projecting transversely.

- A lever (D) is pivoted to the arm (C).

- The inner end of the lever (D) is articulated to the coupling-pin (E).

- The outer end (handle) of the lever (D) projects to the side of the car-platform.

- Function: To uncouple the cars, the operator stands safely at the side of the train and depresses the lever (D). This action lifts the coupling-pin (E), uncoupling the cars without requiring the operator to go between them. The lever may also be connected by a chain to the car platform for remote uncoupling.

- Locking Mechanism (Throwing Coupling Out of Operation):

- The outer end of the lever (D) is provided with a shoulder (d).

- A catch (G) is pivoted to the arm (C).

- Function: When the coupling is to be disabled (e.g., when moving cars without coupling them), the operator depresses the lever (D) to raise the pin (E), and the catch (G) is engaged with the shoulder (d). This securely locks the lever (D) down, holding the coupling-pin (E) in an elevated position so it will not drop when a link enters.

Historical Significance and the Inventor

Turner Byrd, Jr.’s 1874 patent is a critical development in railroad safety during a period when the link-and-pin coupler was the leading cause of death and injury among railroad workers.

- The Problem of Link-and-Pin Couplers: The common link-and-pin system was notoriously dangerous. Coupling or uncoupling required workers to go between moving cars to manually guide the link, drop or lift the pin, and risk being crushed or losing limbs. These injuries were so frequent that they were called the “railroad toll.”

- Safety Precursor: Byrd’s invention is an early, vital attempt to introduce “safety appliances” that minimized the need for workers to enter the “danger zone.” His side-actuated lever directly foreshadows the core safety requirement later mandated by the Federal Safety Appliance Act of 1893, which effectively required couplers to be operable without operators having to go between the ends of the cars.

- The Inventor (Turner Byrd, Jr.): While personal details are limited in the record, Byrd was an inventor working in Michigan who contributed a practical, life-saving mechanical improvement to the nation’s most dangerous industrial setting.

Relation to Current Items

Byrd’s remote uncoupling concept is foundational to modern rail systems:

- Remote Uncoupling: The principle of operating the coupler from the side of the car is a feature retained in all modern Janney (knuckle) couplers used today across North America. Workers use a coupler release lever (often called a “lock lift lever”) extending from the knuckle assembly to the side of the car, allowing uncoupling without entering the dangerous space between the rail ends.

- Disabling Mechanisms: The ability to mechanically lock a coupling system out of operation (using catch G and shoulder d) is conceptually related to various modern safety locks, cut-outs, and permanent setting mechanisms used in industrial machinery to hold devices in a safe, non-functioning state during maintenance or when the function is not needed.