The patent by Walter H. Sammons of Philadelphia, Pennsylvania, describes new and useful Improvements in Combs (Patent No. 1,363,059, 1920). The invention relates to hair straightening or kink removing combs which are heated before application to the hair. The main objective is to provide a comb that overcomes the inherent disadvantages of prior heated combs, specifically the risk of damaging the hair and the injury to the hands of the user.

Inventor Background: Walter H. Sammons

Walter H. Sammons was an inventor focusing on personal care and grooming tools. His invention came at a time when the hair care industry for African American hair was expanding rapidly. He designed a product that prioritized safety and control, directly addressing the risks associated with the high, unregulated heat required for hair straightening.

Invention and Mechanism (Simplified)

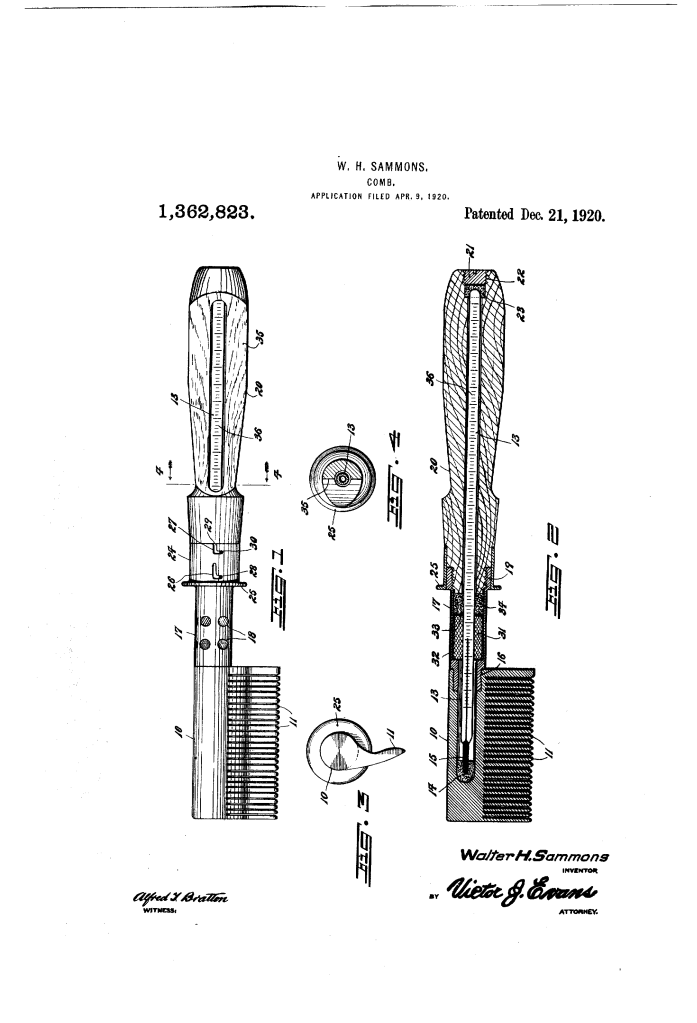

The improved heated comb integrates a thermometer inside the comb head and uses several layers of insulation and a unique airflow chamber to protect the user’s hand.

- Safety Monitoring (Key Innovation):

- Hollow Comb Head (10): The metal comb head is cored out to form an axially central chamber.

- Integrated Thermometer (13): A thermometer is housed internally within this chamber and extends longitudinally into the handle.

- Sight Opening (35): The handle (20) is cut away or slotted, allowing the user to read the temperature gradations (36) on the thermometer at a glance.

- Function: This allows the user to ensure the comb is heated to the requisite degree before application, preventing burning or damage to the hair.

- Advanced Heat Insulation (Hand Safety):

- Insulating Handle (20): Made of hard wood or other suitable heat-resisting material.

- Asbestos Filler (34): A non-conductor or insulator (asbestos filler) is tightly packed within the comb head extension (17) at the connection point to the handle.

- Function: This thick insulation effectively eliminates heat conduction to the handle (20) and sleeve (24), protecting the user’s hands.

- Cooling and Protection:

- Perforated Extension (17): A cylindrical extension connects the heated comb head to the handle. It is perforated (18) to create a cooling chamber (31).

- Gauze Tube (32): A fine gauze tube acts as a screen to prevent dirt from entering the cooling chamber (31).

- Flanged Sleeve (24): A locking sleeve has an outwardly flared flange (25).

- Function: The perforated chamber reduces heat conduction, and the flange acts as a physical obstruction to prevent the user’s fingers from accidentally contacting the heated metal comb head (10) or extension (17).

Concepts Influenced by This Invention

Sammons’s comb influenced subsequent thermal styling tools and safety mechanisms by pioneering the direct integration of temperature feedback and multi-stage insulation.

- Integrated Temperature Monitoring: The core concept of housing a thermometer axially within the heating element with a sight-opening in the handle for direct reading influenced the design of modern thermal processing tools and consumer electronics. This is the precursor to the integrated digital displays and temperature gauges found on modern curling irons, flat irons, and soldering irons .

- Multi-Stage Thermal Isolation: The use of multiple sequential insulating layers—including a cooling air chamber (31), a bulk non-conductor (asbestos filler 34), and a heat-resistant handle (20)—influenced the engineering standards for safety in all high-temperature handheld tools.

- Ergonomic Safety Barriers: The design feature of the flared flange (25) serving as a physical guard to prevent accidental contact with the heated working part is a standard ergonomic safety requirement in industrial tools, kitchen appliances, and personal electronics.

- Safety and Quality Control in Grooming: The invention was a significant early development in making the hair straightening process safer and more consistent, directly influencing the professionalization and standardization of thermal styling technology.