Hose-Leak Stop (Clatonia Joaquin Dorticus, No. 629,315)

The patent by Clatonia Joaquin Dorticus describes a new and useful improvement in Hose-Leak Stops (Patent No. 629,315, 1899), intended to be closed and locked about fire or other hose to stop the escape of fluid from a burst or leak. The improvements focus on increasing the sufficiency and positive operation of the stop, particularly securing it tightly on different hose sizes.

Inventor Background: Clatonia Joaquin Dorticus

Clatonia Joaquin Dorticus was an African-American inventor known for his ingenuity in solving commercial and industrial problems, with patents in photography and shoe finishing. This invention addresses a critical safety and utility need—the ability to quickly fix a burst hose in high-pressure situations, such as firefighting—by creating a robust, adjustable clamp.

Invention and Mechanism (Simplified)

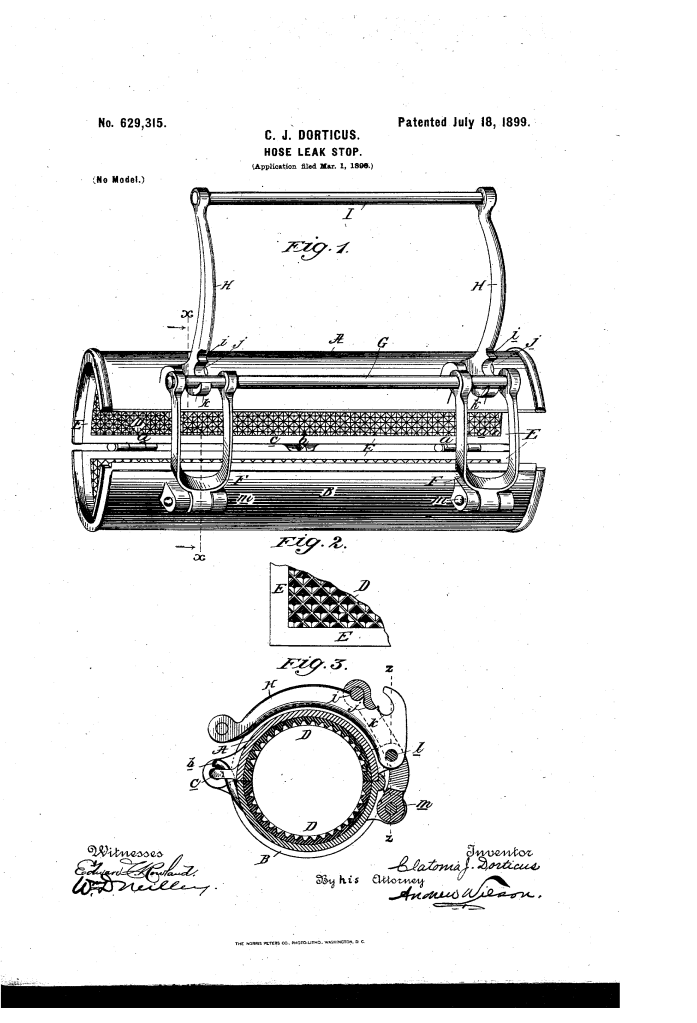

The device is a hinged, lever-locked clamp that uses a uniquely ribbed rubber patch to seal the leak effectively under pressure.

- Hinged Metal Body: The leak stop is made of two hinged metal sections (A and B).

- The Sealing Patch (Key Innovation): Inside the metal sections is a rubber packing (D). This packing is not smooth; it has a multiplicity of uniformly-distributed and intersecting ribs (ridges) that form depressions or recesses between them.

- Function (Yielding Grip): The ribs provide a large number of yielding contact-points that press tightly against the hose. When pressure is applied, the elasticity of the rubber allows the ribs to compress, creating a wider range for tight adjustment on different size hoses.

- Function (Water Cushion): The recesses form water-cushion pockets. Water escaping from the hose leak enters these pockets, which interrupt and break up the current, minimizing or stopping spurting out from beneath the edges of the stop.

- Over-Center Locking Mechanism: The two sections are locked together by two sets of hinged links and levers:

- U-Shaped Links (F, F): Pivoted to one section (B).

- Hooked Levers (H, H): Pivoted to the other section (A). These levers have a series of sockets ($i, j, k$) for adjustment.

- Locking: The operator hooks the levers (H) onto a cross-bar (G) connecting the U-links (F) and forces the levers inward, throwing the bar (G) beyond the center line of the pivotal points. This is an over-center lock that holds the sections together firmly against any interior hose strain.

- Adjustability: The different sockets ($i, j, k$) on the levers allow the clamp to be securely locked in varying positions, accommodating different hose sizes.

Concepts Influenced by This Invention

Dorticus’s leak stop influenced subsequent industrial sealing and clamping devices by pioneering a ribbed, pressure-damping seal with a robust, adjustable mechanical lock.

- Ribbed/Cushioned Sealing Surfaces: The core concept of a multiplicity of elastic ribs on a gasket to provide yielding contact points and create internal pressure-interrupting recesses influenced the design of modern:

- Pipe Couplings and Clamps: Industrial clamps and pipe repair sleeves that use textured or ribbed rubber seals for superior grip and leak prevention under high pressure.

- Gaskets and O-rings: Specialized gaskets designed with complex profiles (ribs, channels) to maximize the sealing surface and compensate for pressure fluctuations.

- Adjustable Over-Center Locks: The use of the over-center locking principle (where the lock holds securely until the pivot line is crossed) combined with multiple adjustment sockets ($i, j, k$) influenced the design of industrial quick-release latches and pipe repair clamps that must lock down rigidly over components of slightly varying diameters.

- Preserving Hose Elasticity: The design’s goal of maintaining the hose’s elasticity (a “semivielding grip”) to prevent a new break adjacent to the clamp influenced the engineering philosophy of all structural repair wraps and splices.