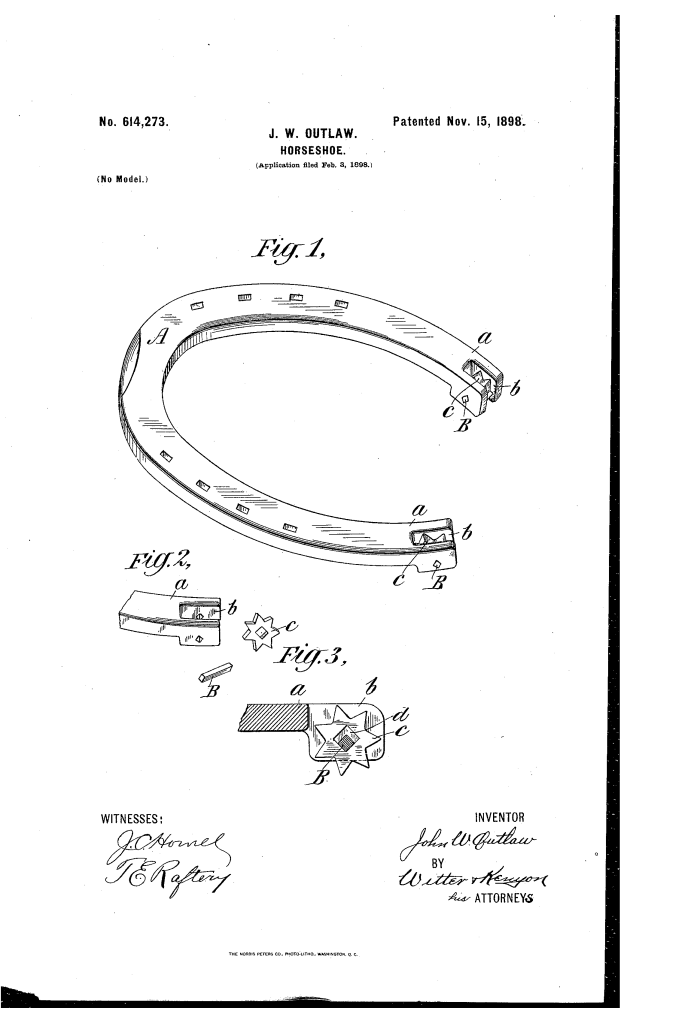

The patent by John W. Outlaw of New York, N.Y., describes an improvement in a Horseshoe (Patent No. 614,273, 1898). The invention is designed to secure a better foothold for horses on smooth or slippery pavements by integrating toothed rollers into the shoe’s heels.

Inventor Background: John W. Outlaw

John W. Outlaw was an inventor residing in New York City. His invention directly addresses a significant urban problem of the late 19th century: the danger and inefficiency of horses slipping on the smooth stone and asphalt pavements of major cities. His solution is a clever application of mechanics to a centuries-old piece of equipment. The assignment of one-fourth interest to Celinda Porter Robinson suggests a financial partnership for the commercial development of the product.

Invention and Mechanism

The improved horseshoe features spring-actuated, toothed rollers designed to lock into a non-slipping position under the horse’s weight.

1. Roller and Housing

- Horseshoe (A): Made in the ordinary way, but the heels () are made thicker than usual.

- Vertical Slot (): A vertical longitudinal slot is cut into each heel.

- Toothed Roller (C): A roller made of hardened steel with, preferably, seven points or teeth. One roller is placed in each slot.

2. The Locking/Grip Mechanism (Key Innovation)

- Polygonal Axle and Hole: The roller (C) is mounted on an axle whose section is a polygon (preferably square, as at B in Fig. 3). The hole (

) in the center of the roller is also a corresponding polygon, but larger than the axle.

- Unstable Equilibrium: When the horse lifts its foot, the roller is free to turn on the axle.

- Locked Grip: When the horse puts its weight on the shoe, the following occurs:

- The weight forces the roller upward in the slot.

- The polygonal hole in the roller slides into contact with the axle (e.g., a corner of the square hole contacts a side of the square axle), and the roller takes a locked position (B in Fig. 3) that is one of stable equilibrium.

- In this position, the lowest tooth projects below the heel of the shoe, providing a firm hold upon the slippery ground.

- Release: When the weight is removed, the roller is free to turn again, bringing other teeth into use.

Concepts Influenced by This Invention

Outlaw’s design influenced mechanical traction and anti-slip systems by pioneering a clever application of weight-actuated, differential locking.

- Weight-Actuated Grip/Traction: The core concept of using the load (the horse’s weight) to automatically engage a structural feature (the projecting tooth) that enhances grip influenced the design of:

- Safety-Grip Hardware: Mechanisms in ladders, temporary scaffolding, and specialty feet that automatically engage spikes, teeth, or high-friction pads only when compressed by a load.

- Non-Circular Differential Locking: The ingenious use of a polygonal (square) axle and a slightly larger polygonal hole to create a stable, non-rotatable lock only when pressure is applied influenced the design of various mechanical ratchets, clutches, and detent mechanisms where a component is free to spin until subjected to a sudden force or load.

- Embedded Traction Systems: The permanent embedding of a durable, high-friction element (the steel roller) into a wear-prone base (the horseshoe heel) is a principle used in modern studded tires, safety stair treads, and industrial flooring to create reliable, long-term anti-slip surfaces.