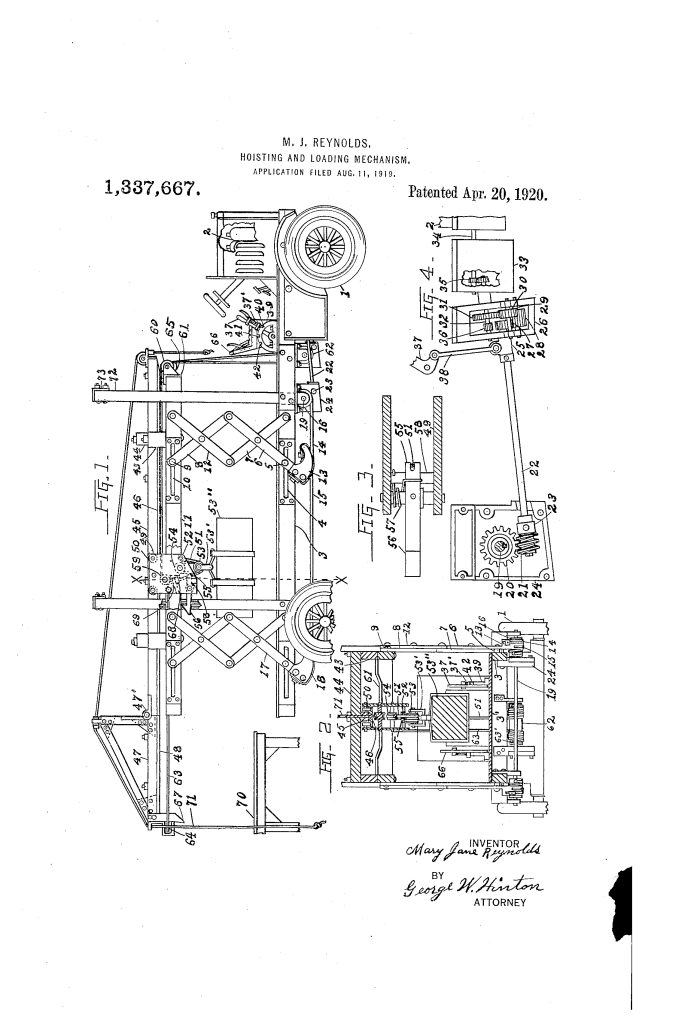

Hoisting and Loading Mechanism (Mary Jane Reynolds, No. 1,337,667)

The patent by Mary Jane Reynolds of St. Louis, Missouri, describes a Hoisting and Loading Mechanism (Patent No. 1,337,667, 1920). This invention is a highly versatile, vehicle-mounted crane and conveyor system designed to allow a single operator to lift heavy goods from the ground or second-story windows and deposit them onto a truck or wagon. Reynolds’s design is notable for its use of lazy tongs (scissor lifts) to adjust the height of the mechanism and its ability to fold into a compact space when the vehicle is in motion.

Inventor Background: Mary Jane Reynolds

Mary Jane Reynolds was an African American inventor based in St. Louis during the early 20th century. Her 1920 patent addressed a critical need in the logistics and moving industries: the lack of portable, high-reach lifting equipment. Before the widespread use of hydraulic lift gates, loading heavy items onto trucks was dangerous and labor-intensive. Reynolds’s invention utilized sophisticated power-transmission gears and mechanical linkages, demonstrating her expertise in industrial design and her ability to engineer a complex, mobile solution for the burgeoning motor-truck industry.

Key Mechanical Components & Functions

The mechanism is built upon a standard truck chassis and consists of an adjustable lift and a traveling load carrier.

1. The Lazy Tongs Support (5, 7, 12)

- Adjustable Height: The main lifting frame is supported by four sets of lazy tongs (5, 7, 12)—essentially a scissor-lift structure.

- Sliding Pivots: The lower pivots (5) slide in slots (4) in the truck sills.

- Function: When the operator winds the cables, the lazy tongs expand vertically, lifting the tram rail (46) to any desired height, such as level with a second-story window.

2. The Tram Rail and Extension (46, 48)

- The Track: A tram rail (46) is secured to a longitudinal girder supported by the lazy tongs.

- Extension: To reach further back or into a building, a tram rail extension (48) is hinge-connected to the main rail.

- Function: This creates a continuous overhead track that can protrude beyond the back of the truck to reach the cargo.

3. The Load Carrier and Hoist (49, 51, 53)

- The Trolley: A load carrier (49) equipped with wheels (50) runs along the tram rail.

- Hoisting Cable (51): A cable passes from a winding drum over pulleys in the carrier and down to a sling pulley (53) attached to the load (53).

- Function: The operator can first winch the load vertically from the ground and then draw the carrier along the rail to position the load directly over the truck bed.

4. The Automatic Holding Hook and Button (56, 68) (Key Innovation)

Reynolds engineered a safety system to prevent the load from dropping or the carrier from sliding prematurely.

- Holding Hook (56): An oscillatably mounted, bifurcated hook on the carrier engages an abutment (67) on the rail.

- Function: This locks the carrier in place at the end of the rail while the load is being hoisted.

- The Button (68): A “button” is secured to the hoisting cable.

- Automatic Release: Once the load is fully hoisted, the button (68) hits a stop (69), which triggers the release of the hook (56). Only then can the carrier begin to travel forward along the rail.

5. Power Transmission (20, 21, 27)

- Worm Gear Drive: The winding drums are driven by a worm gear (20) and worm (21).

- Engine Integration: The system is geared directly to the truck’s engine shaft (34).

- Function: This allows the operator to use the truck’s own motor to power the lift and the hoist, controlled via a lever (37) in the cab.

Improvements Over Standard Loading Methods

| Feature | Manual/Standard Loading | Reynolds’s Hoisting Mechanism |

| Labor Requirement | Required multiple men to lift/move heavy bulk. | Operated by a single individual using engine power. |

| Reach | Limited to the height of the truck bed. | Lazy tongs can reach second-story windows or high docks. |

| Safety | High risk of dropping cargo or injury. | Automatic locks and button-stops manage load transitions. |

| Portability | Fixed cranes were not mobile. | Folds down into a compact space for travel on the truck. |

Significance to Industrial Engineering

Mary Jane Reynolds’s hoisting and loading mechanism influenced the development of mobile material handling and integrated logistics.

- The Scissor-Lift Principle: Her use of lazy tongs for heavy industrial lifting on a vehicle was an early precursor to modern scissor-lift trucks and aerial work platforms.

- Automatic Sequencing: The logic of using a “button” on a cable to trigger a mechanical release is a fundamental principle in automatic machinery, ensuring that one phase of an operation (hoisting) is completed before the next (traveling) begins.

- Power Take-Off (PTO): By gearing her mechanism to the truck’s engine, Reynolds utilized an early form of Power Take-Off, a standard feature in modern utility trucks (like tow trucks or dump trucks) today.

- Modular Extensions: The hinged rail extension allowed for a flexible “footprint,” a concept now common in telescopic cranes and boom arms.