Heating Furnace (Alice H. Parker, No. 1,325,905)

The patent by Alice H. Parker of Morristown, New Jersey, describes a Heating Furnace (Patent No. 1,325,905, 1919). This invention is a landmark in domestic engineering, representing the first design for a gas-powered central heating system. Parker’s furnace was designed to provide a cleaner, more efficient alternative to the coal and wood-burning furnaces of the early 20th century, which required constant manual labor and created significant soot and ash.

Inventor Background: Alice H. Parker

Alice H. Parker was a pioneering African American inventor whose 1919 patent fundamentally changed how we regulate the temperature of our homes. Her invention was born from the cold winters of New Jersey and the desire for a system that provided “greater flexibility” in operation. Before Parker, heating a house meant maintaining a single massive fire in the basement that heated the whole house indiscriminately. Parker’s use of natural gas—and her vision of zone heating—laid the direct groundwork for modern thermostats and centralized HVAC systems.

Key Mechanical Components & Functions

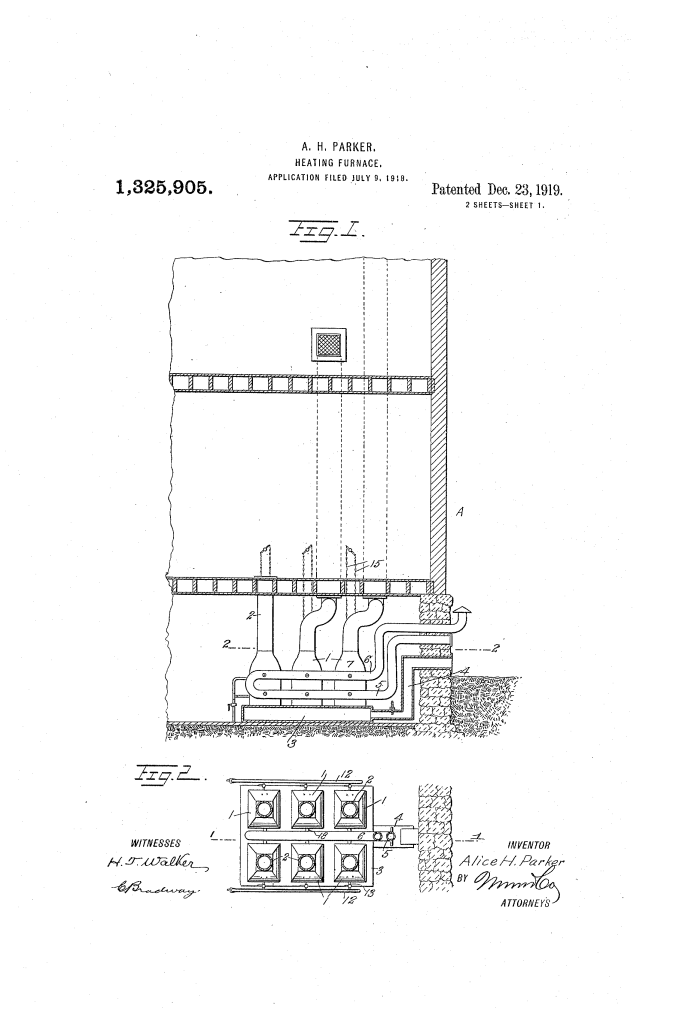

The furnace is composed of multiple independent heating units supplied by a single source of cold air and gas.

1. The Multi-Unit Design (1)

- Modularity: Instead of one large combustion chamber, the furnace comprises a plurality of heating units (1).

- Individual Control: Each unit is connected to a specific hot air duct (2) leading to a different room or floor.

- Function: This allows for zone heating. If a room is not in use, its specific heating unit can be turned off, saving significant fuel and labor.

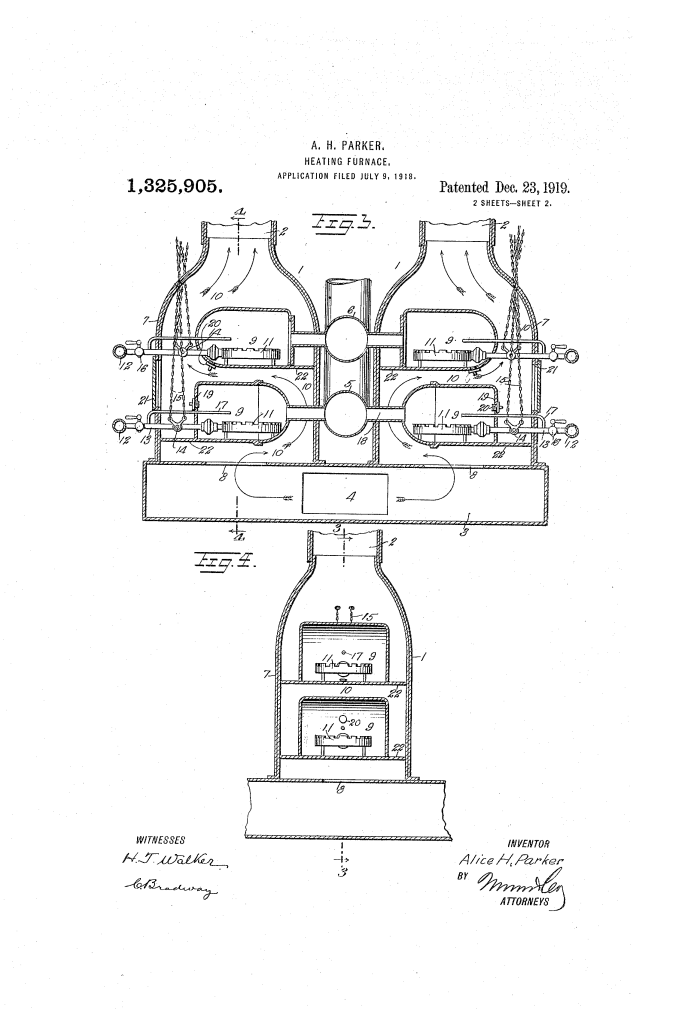

2. The Gas Burner and Pilot (11, 17)

- Fuel Source: Parker’s furnace utilized gas, a radical shift from the solid fuels of her time.

- Pilot Burner (17): Each combustion chamber contains a pilot light (17).

- Function: This small, constant flame ensures that the main gas burner (11) ignites instantly as soon as the gas is turned on, removing the need to manually light a fire with matches and kindling.

3. The Combustion Chambers (9)

- Super-Imposed Chambers: Inside each casing, two or more combustion chambers (9) are stacked one above the other.

- Heat Exchange: The chambers are separated from the walls of the casing (7) to form a passage (10) for the air.

- Function: As cold air rises from the cold air box (3), it circulates entirely around these hot metal chambers, absorbing heat before being pushed into the ducts.

4. The Tortuous Path / Baffle Plates (22) (Key Innovation)

- Baffle Plates (22): Parker included extensions or baffle plates at the bottom of the chambers.

- Serpentine Flow: These baffles are placed on alternate sides of the units.

- Function: This forces the air to follow a tortuous or serpentine path rather than rising in a straight line. This increases the “dwell time” the air spends in contact with the hot surfaces, ensuring the air is heated to a much higher temperature before exiting the unit.

Improvements Over Existing Technology

| Feature | Standard 1910s Coal Furnaces | Parker’s Gas Heating Furnace |

| Fuel Handling | Required heavy shoveling and ash removal. | Used gas piped directly into the unit; zero manual labor. |

| Temperature Control | “All or nothing” heating for the entire building. | Independent units allow for room-by-room regulation. |

| Cleanliness | Produced smoke, soot, and indoor air pollution. | Gas combustion is cleaner and vented through dedicated pipes (5, 6). |

| Ignition | Required building and tending a new fire daily. | Constant pilot light allows for instant, on-demand heat. |

Significance to HVAC Engineering

Alice H. Parker’s heating furnace influenced the development of climate control and energy efficiency.

- Centralized Gas Heating: Parker proved that gas could safely and effectively provide central heat for a large building, leading to the phase-out of coal-fired residential systems.

- The Concept of “Zoning”: Her design for independent heating units is the mechanical ancestor of modern HVAC dampers and smart home systems that heat only the rooms currently being occupied.

- Heat Exchange Optimization: The use of baffle plates to create a tortuous air path is a foundational engineering principle used in modern boilers and high-efficiency furnaces to maximize thermal transfer.

- Remote Regulation: Parker included pull chains (15) to operate the gas valves from a “point remote from the furnace,” an early mechanical precursor to the wall-mounted thermostat.