Hay-Press (Joseph Ross, No. 632,539)

The patent by Joseph Ross of Vincennes, Indiana, describes certain new and useful Improvements in a Hay-Balers (Patent No. 632,539, 1899). The objectives are to produce a cheap, simple, and portable baling-press that can be knocked down and taken apart for transportation or storage, and to provide a mechanism that bales two or more bales alternately, operating both ends simultaneously.

Inventor Background: Joseph Ross

Joseph Ross was an inventor focusing on agricultural machinery. His invention addresses the logistical challenges of farming in the late 19th century—namely, the need for portable, high-capacity equipment that could be easily moved between fields and stored compactly. The assignment of one-half interest to John Nordhaus suggests a commercial partnership.

Invention and Mechanism (Simplified)

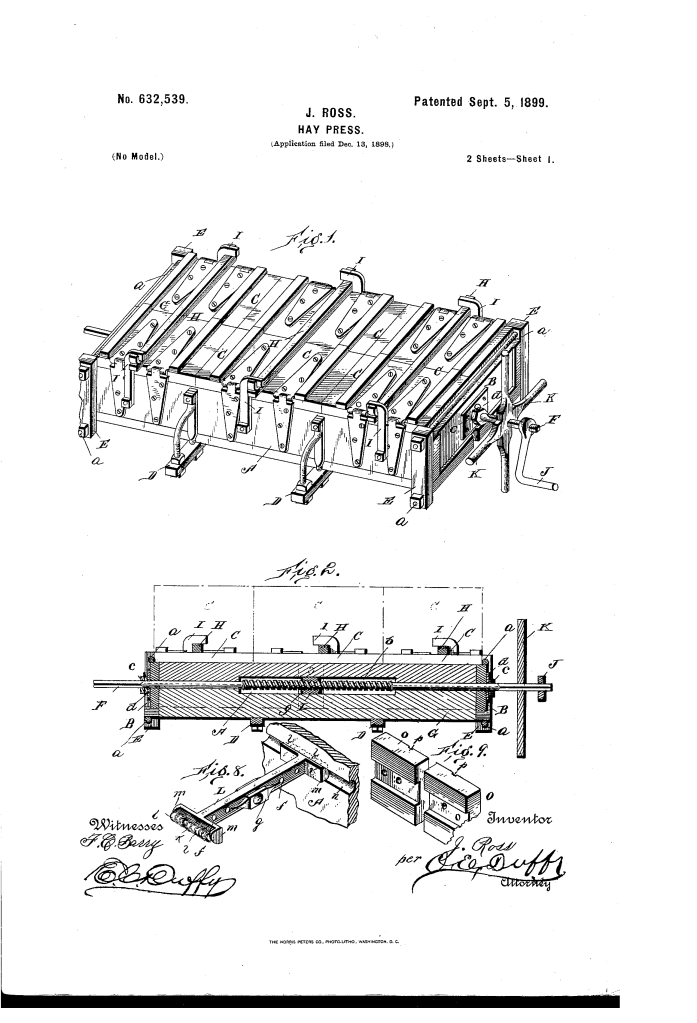

The press is a double-sided, knock-down box frame that uses a single central screw to drive a follower (compressor) back and forth, pressing bales alternately in two chambers.

- Knockdown Frame (Modularity):

- Assembly: The press box is built from separate sides (A), ends (B), and a bottom, held together transversely by yokes (E) and longitudinally by the central screw-shaft (F) and its collars ($c$).

- Function: This construction allows the entire press to be quickly taken apart (“knocked down”) for easy transportation or storage, with all parts being interchangeable.

- Double-Action Compression: A central division-wall (G) runs the length of the press, creating two parallel chambers.

- Operation: A single follower (L) is driven by the screw (F). As it moves, it compresses a bale in one chamber while the other chamber is being filled with hay, allowing for alternate, continuous baling.

- Removal: Each end (B, B) has separate doors (C, C) for the removal of the compressed bales.

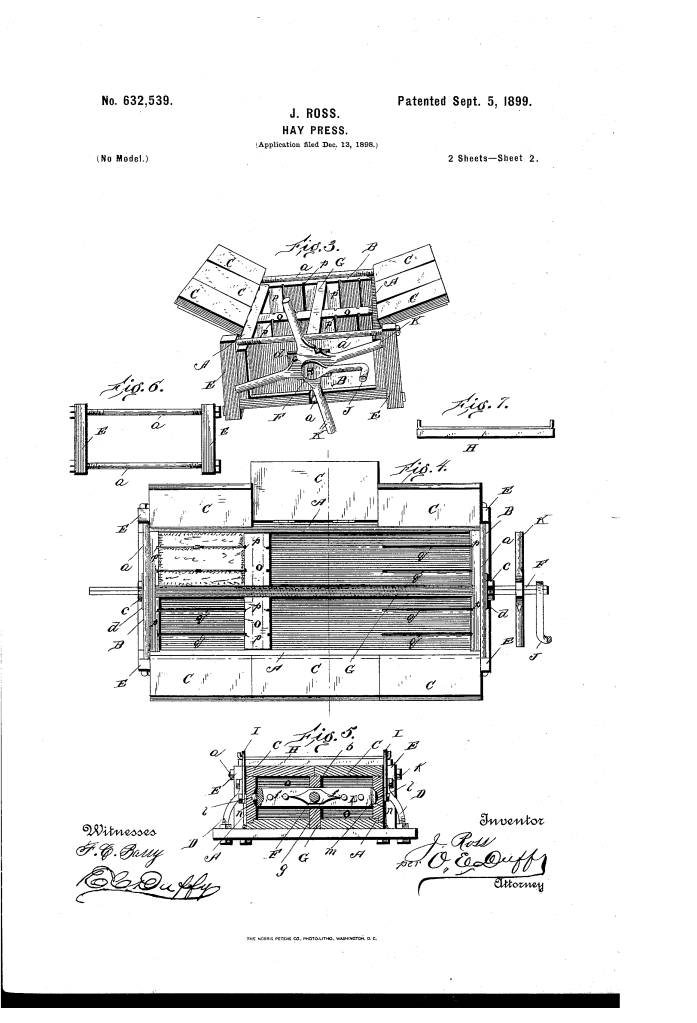

- Anti-Buckling Cross-Head (Key Innovation):

- Cross-Head (L): This unit carries the followers (O) and travels along the central screw (F). It has a deep, wide, screw-threaded boss (g) to give the screw-shaft a long bearing.

- T-Shaped Ends: The cross-head has T-shaped end pieces that are concaved to hold antifriction balls ($l$) or rollers.

- Guiding: The sides of the box have concave slots ($n$) for the balls ($l$) to work in.

- Function: When hay is unevenly placed (more on one side than the other), the unequal pressure is transferred from the T-shaped ends, through the antifriction balls, directly to the sides of the press box. This process prevents the screw-shaft (F) from buckling or bending, which is a critical safety and durability feature in screw-driven presses.

Concepts Influenced by This Invention

Ross’s hay press influenced subsequent industrial and agricultural machinery by pioneering knockdown construction and integrated load-transfer bearings.

- Knockdown/Flat-Pack Utility: The design philosophy of creating a large, heavy-duty machine that is built from separate, clamped components (yokes E) and can be quickly disassembled for transport or storage influenced the design of modern modular, flat-pack industrial equipment, presses, and outdoor structures.

- Integrated Load-Transfer Bearings (Anti-Buckling): The most significant influence is the T-shaped cross-head with antifriction balls (l) that work in side grooves ($n$). This design ensures that lateral stress is transferred from the central drive shaft (F) to the rigid frame (A). This principle is vital in:

- Screw and Linear Actuators: Mechanisms requiring high-force compression where the drive screw must be protected from buckling stress (axial misalignment).

- Heavy-Duty Guides: Guiding systems that use rolling elements (balls/rollers) to carry offset load directly to the frame walls, maximizing stability and minimizing friction.

- Alternate-Chamber Continuous Processing: The technique of using a single reciprocating mechanism to work alternately on two separate chambers (baling on one side while filling the other) influenced the design of industrial continuous-feed systems and parallel processing lines.