Hand-Power Attachment for Sewing-Machines (Charles T. Christmas, No. 226,492)

The patent by Charles T. Christmas of Riverton, Mississippi, describes a new and improved Hand-Power Attachment for Sewing-Machines (Patent No. 226,492, 1880). The object is to provide an attachment that allows the sewing-machine to be driven by hand alone, or to be used to assist the operation of the machine by foot, thereby relieving the operator of continuous work with the feet.

Inventor Background: Charles T. Christmas

Charles T. Christmas was an inventor residing in Mississippi. His invention is a significant contribution to domestic labor-saving devices, particularly in the post-Civil War era when sewing machines were ubiquitous but still manually powered. His focus was on improving the ergonomics and reducing the fatigue associated with operating the machine.

Invention and Mechanism

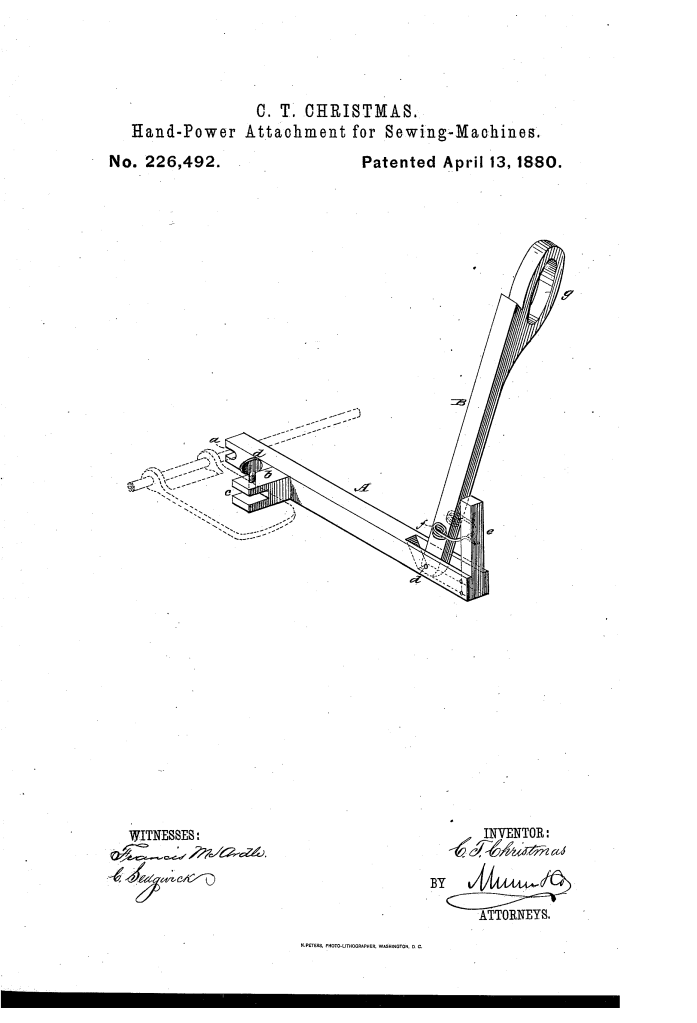

The attachment is a simple, pivotally connected two-part lever designed to transfer manual reciprocating motion from the hand to the machine’s foot treadle.

1. Attachment Structure

- Lever/Rod (A): The main lever of wood or metal.

- Clamping End: Formed with a mortise ($a$) to fit over the treadle-rod ($h’$). A short arm ($b$) with a mortise ($c$) and a thumb-screw ($d$) clamps the lever (A) securely to the treadle-rod.

- Hand-Piece (B): A piece that serves as the handle, hinged by a cross-pin ($d’$) into a mortise at the opposite end of lever (A), allowing it to swing.

- Aperture ($g$): The upper end of the hand-piece has an aperture for easy grasping.

2. Operation and Use

- Engagement: The lever (A) is clamped over the machine’s treadle-rod ($h’$), and the long rod (A) rests on the edge of the machine’s framework.

- Driving: The operator grasps the hand-piece (B) and moves it up and down. This motion is transferred through the lever (A) to the treadle-rod ($h’$), driving the machine.

- Dual Power: The machine can be driven by hand alone, or the hand motion can be used to assist the foot operating the treadle.

3. Storage Feature (Key Innovation)

- Standard ($e$) and Spring-Arms ($f$): A small standard ($e$) attached to lever (A) carries spring-arms ($f$).

- Function: When both hands are required for sewing, the hand-piece (B) can be pushed back and caught between the spring-arms ($f$), which retain it in a stored, non-interfering position.

Concepts Influenced by This Invention

Christmas’s attachment influenced subsequent accessory design by pioneering simple, retrofittable auxiliary power mechanisms for domestic machinery.

- Retrofittable Auxiliary Power: The core concept of a simple attachment that converts one type of user input (hand) to another (foot treadle motion) influenced the design of various power and assist accessories for manual machines. This principle is fundamental to the concept of conversion kits for manual equipment.

- Integrated Storage/Dormant Position: The design incorporating a standard ($e$) and spring-arms ($f$) to quickly secure the handle (B) when not in use influenced the design of modern tools and accessories that have a designated, functional storage or idle position that prevents interference with the main operation.

- Simple Motion Transfer: The use of a directly hinged lever (A) with a clamp to transfer manual reciprocating motion is a robust, low-cost mechanical solution for speed control and user assistance in light machinery.

- Ergonomics for Fatigue Reduction: The invention is a clear precursor to the industrial design goal of mitigating user fatigue by distributing effort across different muscle groups (hands and feet).