🌾 Grain-Binder (Willis Marshall, No. 341,589)

The patent by Willis Marshall of Chicago, Illinois, describes an improvement in Grain-Binders (Patent No. 341,589, 1886). The invention focuses on refining the “Appleby type” binder, a widely used agricultural machine of the era. Marshall’s goal was to improve the tripping-dog mechanism—the component responsible for engaging the binding cycle—making it stronger, more durable, and easier to adjust without tools.

Inventor Background: Willis Marshall

Willis Marshall was an African-American inventor working in Chicago during the height of the industrial revolution in agriculture. His work on the grain binder placed him in direct competition and collaboration with the technological standards set by major firms like McCormick. At the time, Chicago was the world’s hub for farm machinery manufacturing. Marshall’s patent demonstrates a high degree of mechanical sophistication, focusing on “stress points” and “wear patterns” in heavy machinery—showing that he was not just an inventor of new ideas, but a refined engineer of existing industrial systems.

Invention and Mechanism (Simplified)

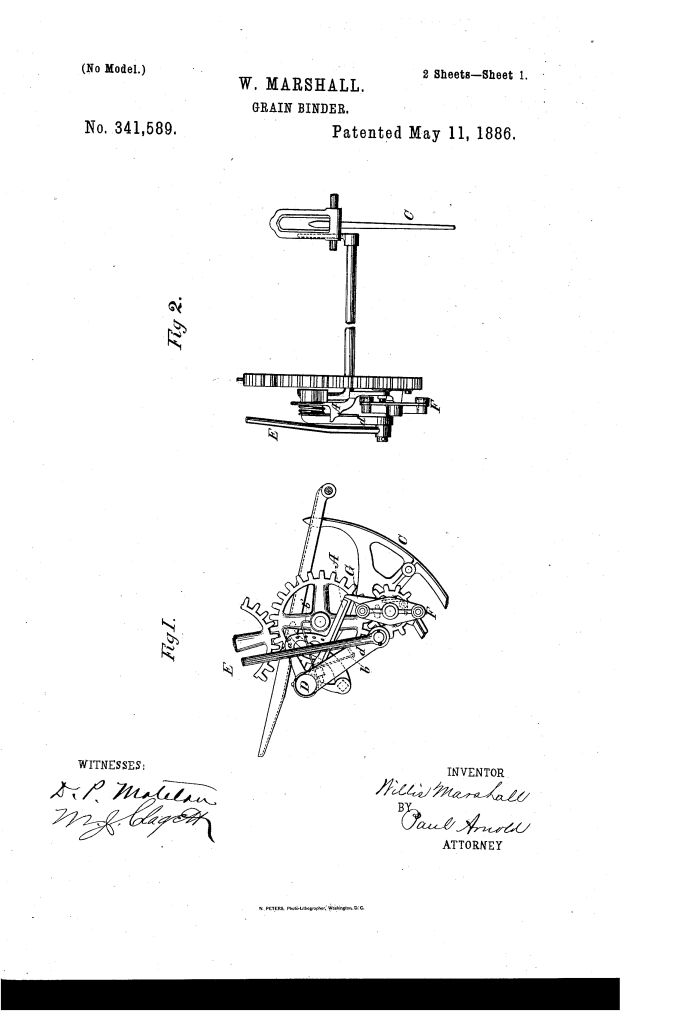

In a grain binder, the machine waits until enough grain has been collected to form a bundle. Once the grain pushes against a lever with enough force, it “trips” the mechanism to tie the knot. Marshall improved the part that handles this “trip.”

1. The Improved Tripping-Dog (A)

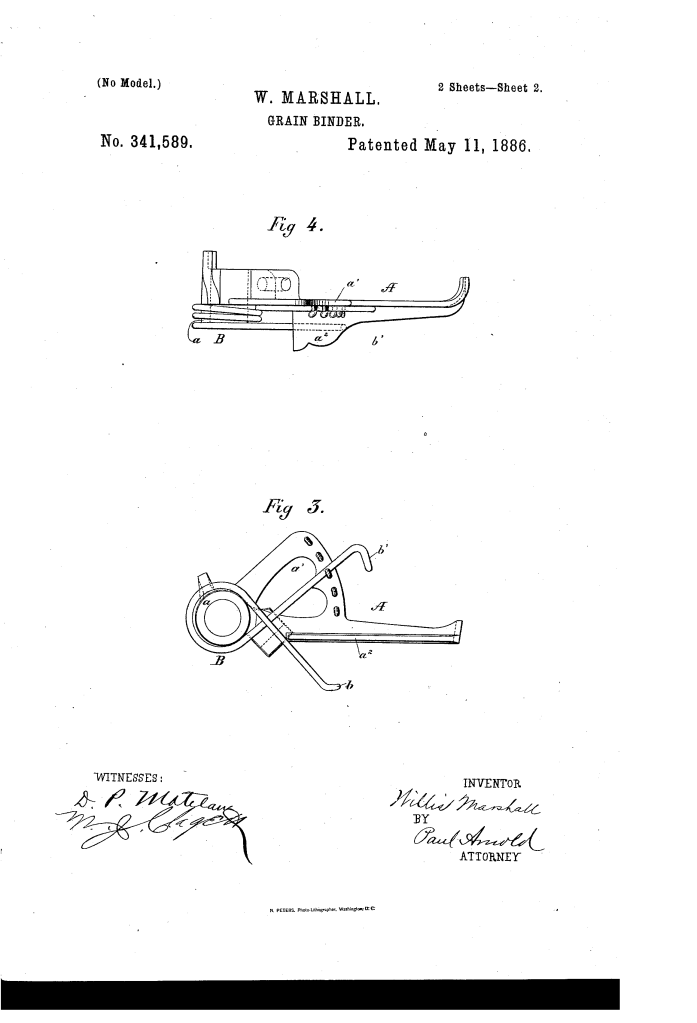

- Hub (a): Marshall designed the tripping-dog (A) with an elongated hub that fits loosely over the binder-arm shaft.

- Notched Flange ($a’$): Unlike previous designs that used a hole bored through the metal (which weakened the part), Marshall added a notched flange or arm ($a’$) to the exterior of the dog.

- Function: This flange provides a series of teeth for the spring to latch onto, eliminating the need for a retaining bolt and preventing the metal from wearing down over time.

2. The Torsion Spring (B) (Key Innovation)

- Coiled Design: Marshall replaced the standard axial spiral spring with a coiled torsion spring (B) that fits directly over the elongated hub of the tripping-dog.

- Tool-Less Adjustment: One end of the spring ($b$) is fixed to the shaft, while the other end ($b’$) is bent into a hook that rests in the notches of the flange ($a’$).

- Function: To change the tension (how much grain it takes to trigger the binder), the operator simply lifts the hook and moves it to a different notch. This dispenses with the need for a wrench or tools in the field, a massive advantage during the time-sensitive harvest season.

3. Simplified Maintenance

- Easy Replacement: To apply or replace the spring, the operator only needs to disconnect the pitman (E) and slide the spring over the crank.

- Result: This eliminated the “spring-retaining bolt” found in older Appleby binders, which was prone to friction, widening the holes in the dog and eventually causing the mechanism to fail.

Concepts Influenced by This Invention

Marshall’s grain-binder improvements influenced the design of agricultural triggers and tension-regulated machinery.

- Tool-Less Field Maintenance: The concept of manual tension adjustment through notched indexing (moving a spring by hand rather than turning a nut) became a staple in farm equipment, where tools are often lost or inconvenient to use in the heat of a harvest.

- Component Strengthening through Geometry: By moving the tension point from a hole inside the part to a flange on the part, Marshall pioneered a “stress-diversion” engineering tactic common in modern automotive and industrial casting.

- Torsion-Based Triggering: The use of a coiled torsion spring over a central hub to regulate a mechanical “trip” is a principle still found in various mechanical sensors and safety release valves.

- Standardization of the Appleby System: Marshall’s work contributed to the longevity of the Appleby binding system, which remained the global standard for mechanical grain harvesting for decades.