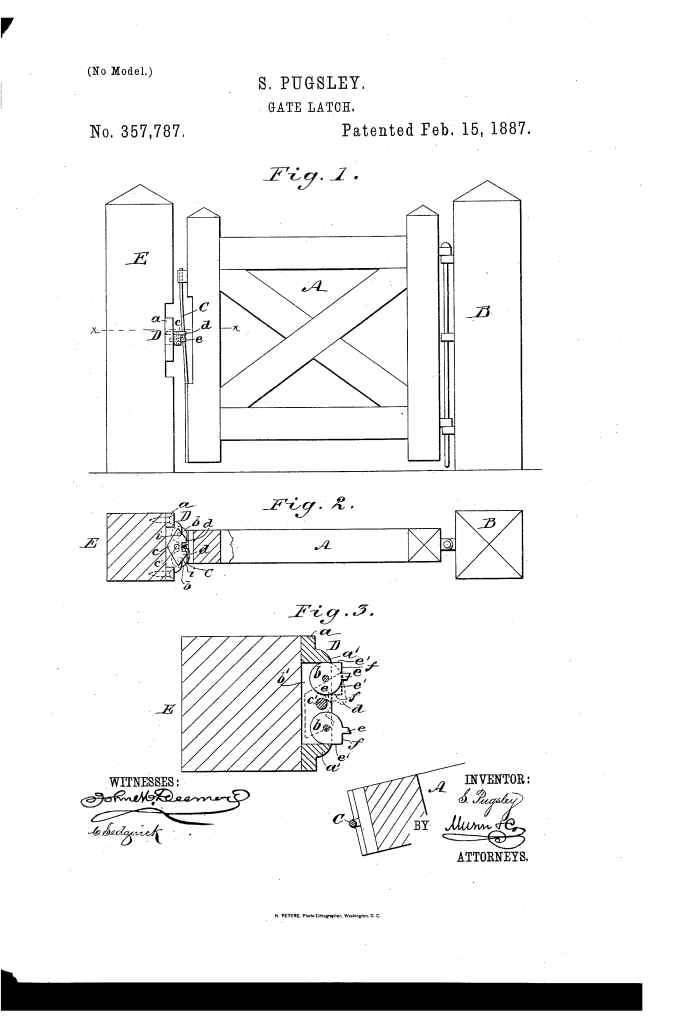

🚪 Gate-Latch (Samuel Pugsley, No. 357,787)

The patent by Samuel Pugsley of New Rochelle, New York, describes an improved Gate-Latch (Patent No. 357,787, 1887). This invention is a mechanical fastener designed for gates that swing in either direction. Pugsley’s primary objective was to create a latch that automatically secures the gate upon closing—regardless of which way it is pushed—while providing a “spring action” that allows for a smooth, frictionless release. His innovation centers on the use of pivoted circular tumblers and a notched plate that work in tandem to trap the latch-rod securely.

Inventor Background: Samuel Pugsley

Samuel Pugsley was an African American inventor and entrepreneur based in Westchester County, New York, during the late 19th century. His 1887 patent addressed a common “pain point” of rural and suburban life: the unreliable gate latch. Standard latches of the time often jammed or failed to catch if the gate swung too fast. Pugsley’s background in mechanical design is evident in the geometric precision of the tumblers, which utilize gravitational and physical stops to ensure the latch always resets to its “ready” position. This patent is a prime example of the practical, hardware-focused inventions that characterized Black innovation in the post-Reconstruction era.

Key Mechanical & Functional Systems

The latch is composed of a fixed frame housing several moving parts that interact with a rod on the gate.

1. The Pivoted Tumblers (b)

- Form: These are nearly circular iron components pivoted within a chamber (h) of the frame.

- Projections and Shoulders (e, e’): Each tumbler has a projection (e) that stands out in the path of the gate’s latch-rod.

- Function: As the gate closes, the rod strikes the tumbler. The shoulder (e’) acts as a stop against the frame, preventing the tumbler from swinging too far. This ensures the tumbler always provides a firm surface to stop the gate’s momentum.

2. The Notched Plate (c)

- Design: A plate pivoted on a pin (c’) with a notched front edge forming two projections (d, d).

- Beveled Edges (i): The outer ends of this plate are angled.

- Function: When the gate-rod strikes the beveled edge, it swings the plate back, allowing the rod to pass into the notch. Once the rod is inside, the plate swings back into place, trapping the rod between the two projections (d, d). This allows the gate to be locked automatically from either direction.

3. The Latch-Rod (C) and Spring Action

- Interaction: The latch-rod (C) is attached to the gate and has a natural “spring action.”

- Frictionless Opening: When pushing the gate open, the rod strikes the shoulder (f) of the tumbler.

- Action: This contact swings the tumbler out of the way, which actually moves the latch-rod inward slightly. This clever bit of geometry allows the rod to clear the latch mechanism without grinding or friction.

Improvements Over Standard Gate Latches

| Feature | Standard 1880s Latches | Pugsley’s Gate-Latch |

| Directionality | Most only worked if the gate swung one way. | Bi-directional; works regardless of swing direction. |

| Security | Gates often “bounced” back open. | Tumbler projection (e) acts as a definitive stop. |

| Wear & Tear | Constant friction led to metal fatigue. | Shoulder (f) mechanism enables frictionless opening. |

| Automaticity | Required manual resetting or lifting. | Gravity/Pivot logic ensures it’s always ready to catch. |

Significance to Mechanical Engineering

Samuel Pugsley’s gate-latch influenced the development of automatic fastening systems and bi-directional hardware.

- The Double-Acting Pivot: Pugsley’s use of symmetrical tumblers to handle force from two directions is a foundational principle in modern swinging door hardware used in commercial kitchens and hospitals.

- Momentum Management: By using the “stop shoulder” (e’) to absorb the gate’s impact, Pugsley demonstrated an early understanding of structural load distribution in small-scale mechanics.

- Friction Reduction: The “shoulder f” logic—using the act of opening to move the latch-rod away from the strike point—is a precursor to the low-friction strike plates used in modern high-traffic entryways.

- Modular Simplicity: The latch was designed as a self-contained unit (Frame a) that could be easily secured to any post, anticipating the universal mounting standards of modern hardware.