Gage (Elijah H. Holmes, No. 549,513)

The patent by Elijah H. Holmes of Prairie View, Texas, describes an improvement in a gage (or marking-gage), a tool used to scribe a line parallel to an edge of a workpiece. The primary objective is to improve the visibility of the marking point, allowing the operator to continuously see the progress of the line without having to lift or turn the tool.

Invention and Mechanism

The improvement centers on the design of the marking-point holder and the end of the beam to maximize the operator’s line of sight.

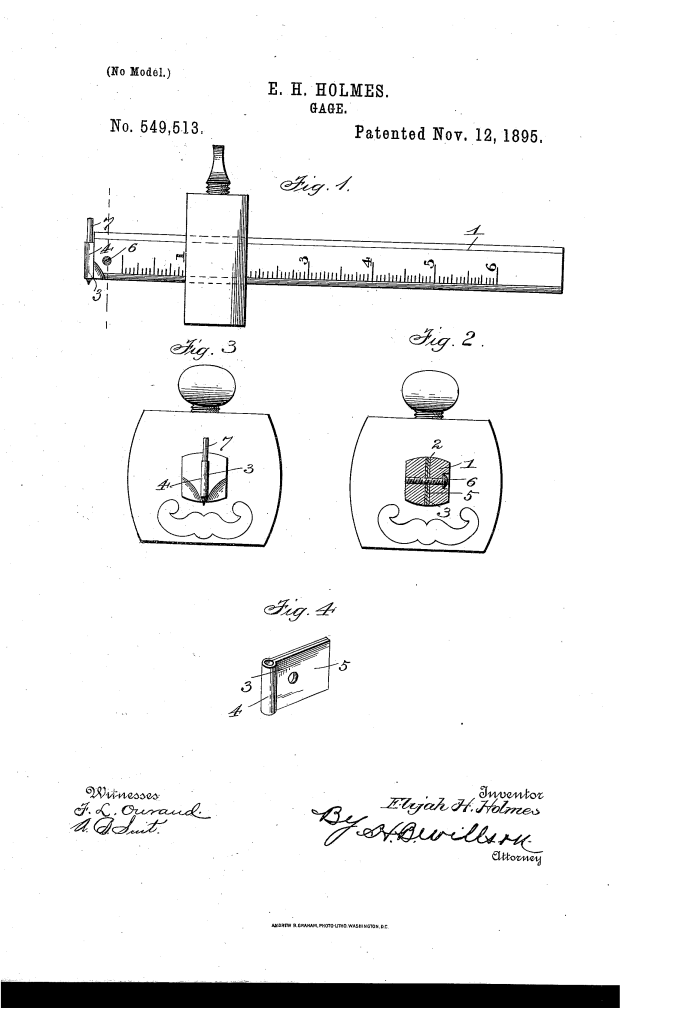

1. Beam and Clamp Assembly

- Beam (1): The main body of the gage, provided with a slot or saw-kerf (2) at one end.

- Clamp (3): A specialized piece composed of:

- A tubular portion (4) designed to hold the scribing point.

- Parallel laterally-projecting wings (5) designed to fit into the saw-kerf (2) of the beam.

- Clamping Mechanism: A screw (6) works transversely through the beam. As the screw is tightened, it draws the separated ends of the beam tightly against the wings (5) of the clamp, effectively holding the clamp (and the marker) in position.

- Scribing Point (Marker, 7): Located in the tubular portion (4) of the clamp.

2. Visibility Feature

- Chamfered Beam End: The end of the beam (1) near the marking point is chamfered (cut away) to be somewhat concave on both sides of the point.

- Function: This concave chamfer removes material from the beam that would normally obstruct the operator’s view. This allows the operator to see the point of the marker (7) at all times, directly observing the line being scribed without having to turn the gage forward.

- Benefit: This visibility saves time because the marker doesn’t need to lift the gage to check proximity to cross-lines and prevents the error of “scribing beyond boundary-lines of mortise or tenon.”

Historical Significance and the Inventor

Elijah H. Holmes’s 1895 patent is an example of an inventor refining a basic hand tool for increased precision and efficiency, a common theme in the late 19th-century workshop.

- The Problem of the Traditional Gage: Traditional marking gages, which had a spur marking point and a square head, often required the operator to lean over or turn the gage to see exactly where the point was scribing, particularly when approaching a corner or boundary line. This interruption slowed the work and introduced opportunities for error.

- Ergonomics and Efficiency: Holmes’s design addressed the ergonomics and practical speed of the skilled woodworker. By making the marking point visible from the operator’s standard working angle, he created a tool that was both faster to use and more precise, reducing material waste.

- The Inventor (Elijah H. Holmes): Holmes, residing in Prairie View, Texas, contributed a practical improvement to the woodworking and carpentry trades, demonstrating the continuous need for innovation even in the simplest hand tools.

Relation to Current Items

Holmes’s improvement on the marking gage relates directly to modern design principles in tools and visual instrumentation:

- Visual Field Optimization: The technique of chamfering or sculpting material around a working point to improve visibility is a standard design principle in modern tools, especially in jigs, fixtures, and power tools like routers, circular saws, and hand planes, where the operator’s view of the cutting edge is crucial for safety and accuracy.

- Toolless Adjustment: While Holmes’s clamp uses a screw, the idea of integrating the clamping mechanism for the point (3) into the beam (1) is a precursor to modern quick-release and toolless adjustment mechanisms used on calipers and measurement tools.

- Marking Gages Today: Modern marking gages, particularly those favored by fine woodworkers, often use wheel cutters instead of spurs. These cutters are generally located on the end of the beam, rather than being inset, achieving the goal of superior visibility that Holmes sought to deliver through his chamfered design.