🍊 Fruit-Press (Madeline M. Turner, No. 1,180,959)

The patent by Madeline M. Turner of Oakland, California, describes an automated Fruit-Press (Patent No. 1,180,959, 1916). This invention was a sophisticated mechanical solution for the high-volume extraction of juice from citrus fruits like oranges and lemons. Turner’s machine was designed to automate the entire process: feeding the fruit, slicing it in half, pressing the juice, and ejecting the remains, all without manual handling of the fruit itself.

Inventor Background: Madeline M. Turner

Madeline M. Turner was an African American inventor and entrepreneur. Her fruit press, patented in 1916, was so innovative that it was exhibited at the Panama-California Exposition in San Diego. During an era when citrus juicing was a laborious hand-task, Turner applied principles of differential mechanical linkage and reciprocating plungers to create a commercial-grade appliance. Her invention is a landmark in the history of kitchen and food-processing automation, demonstrating a masterful grasp of synchronized mechanical movement.

Invention and Mechanism (Simplified)

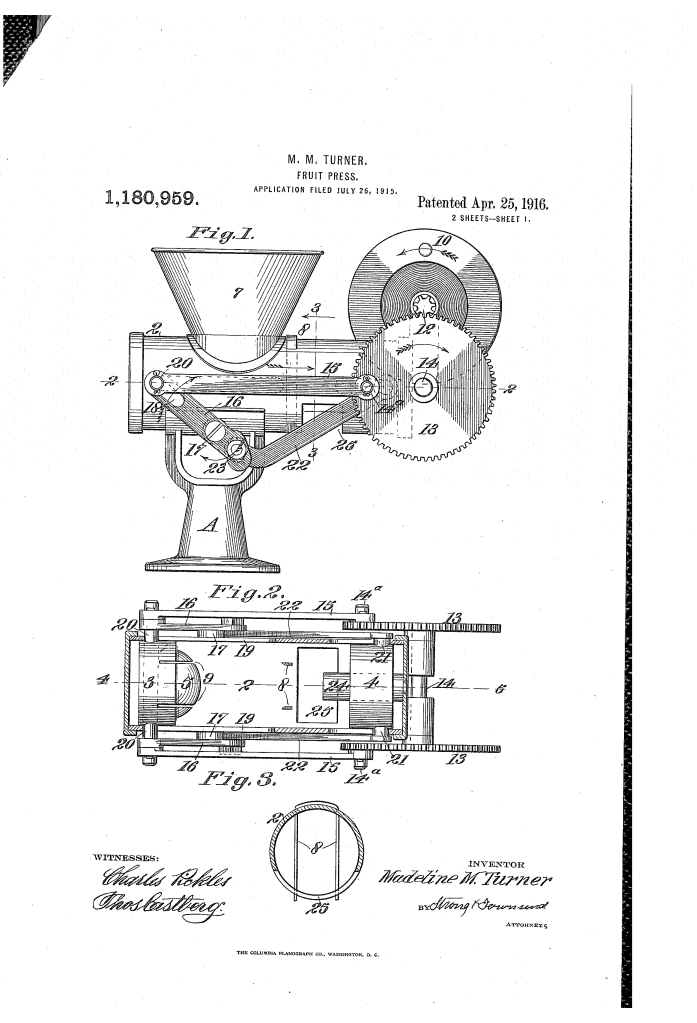

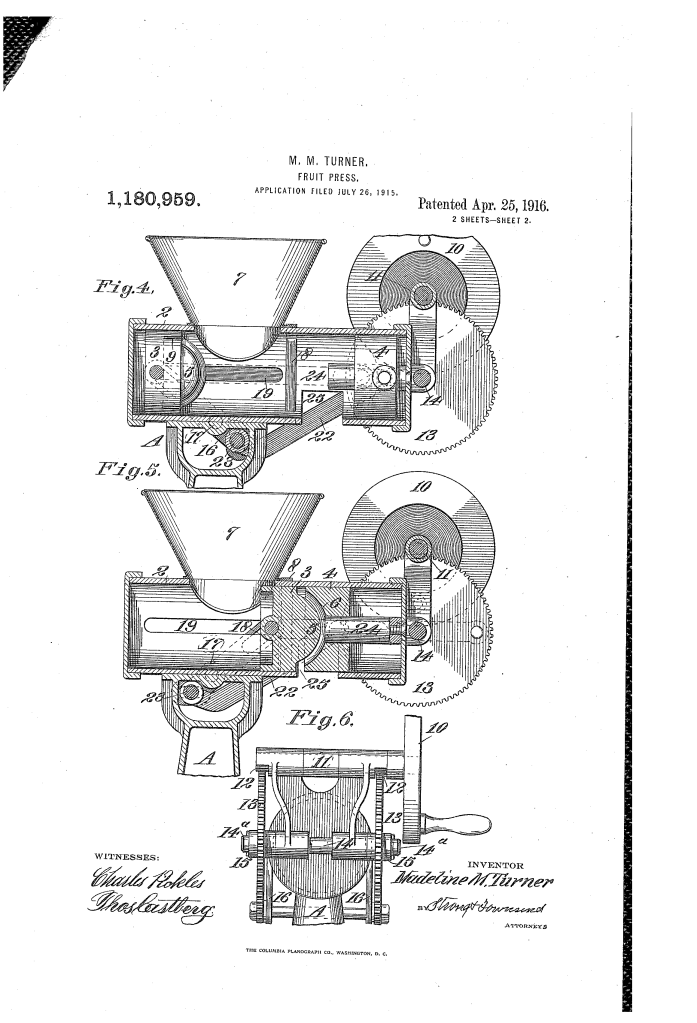

The machine operates through two horizontal plungers that move at different speeds to trap, cut, and squeeze the fruit.

1. The Hopper and Feed (7)

- The Reservoir (7): Fruit is loaded into a hopper-shaped reservoir on top of the cylinder (2).

- Gravity Feed: When the plungers are fully retracted, a single fruit drops through the bottom of the hopper into the pressing chamber.

2. The Differential Plungers (3, 4)

The machine features two synchronized plungers that approach each other with unequal movements.

- Plunger 3 (Convex Head): This plunger has a longer stroke. It travels forward to push the fruit across the cutting knives.

- Plunger 4 (Concave Head): This plunger has a shorter stroke. It moves forward to meet Plunger 3 at the point of greatest compression.

- Rocker Arms (16): The movement is governed by rocker arms pivoted at a specific point (17). Because one end of the arm is longer than the other, one plunger moves faster and further than its counterpart.

3. The Stationary Knives (8)

- The Slicing Action: As Plunger 3 advances, it forces the fruit against vertically disposed stationary knives (8).

- Slotted Design: The convex head of Plunger 3 has slots (9) that allow it to pass right through the knives, ensuring the fruit is sliced completely before the pressing begins.

4. The Compression and Ejection (24) (Key Innovation)

- Compression: The two heads (concave and convex) meet, thoroughly compressing the fruit and forcing the juice through an opening (25) in the bottom.

- The Stationary Bar (24): A fixed bar extends through the center of the concave plunger (4).

- Function (Pressing): When Plunger 4 moves forward, its face becomes flush with the end of this bar, creating a continuous pressing surface.

- Function (Ejection): When the plungers retract after juicing, the bar stays still while the plunger moves back. This makes the bar “protrude,” effectively acting as a pusher that knocks out the squeezed skins and residue, preventing the machine from clogging.

Improvements Over Manual Juicing

| Feature | Manual Hand-Pressing | Turner’s Fruit Press |

| Efficiency | One half at a time; slow. | Continuous cycle; handles whole fruits automatically. |

| Juice Yield | Depends on manual strength. | Controlled mechanical compression extracts maximum juice. |

| Sanitation | Direct contact with hands. | Fully enclosed process; no hand-to-fruit contact. |

| Maintenance | Messy; seeds and pulp get stuck. | Automatic ejection bar (24) clears residue in every cycle. |

Significance to Food Engineering

Madeline M. Turner’s fruit press influenced the development of commercial food processing equipment and synchronized machinery.

- Automated Cycle Design: Turner’s machine is a classic example of an automated work cycle (Feed -> Cut -> Press -> Eject). This sequential logic is the foundation of modern high-speed bottling and canning lines.

- Differential Linkage: The use of rocker arms to create two different movements from a single power source is a fundamental engineering technique used to save space and reduce the number of motors required in a machine.

- Integrated Cleaning: By designing the ejection bar ($24$) to clean the plunger automatically as part of the return stroke, Turner anticipated the modern focus on Self-Cleaning Mechanisms in industrial design.