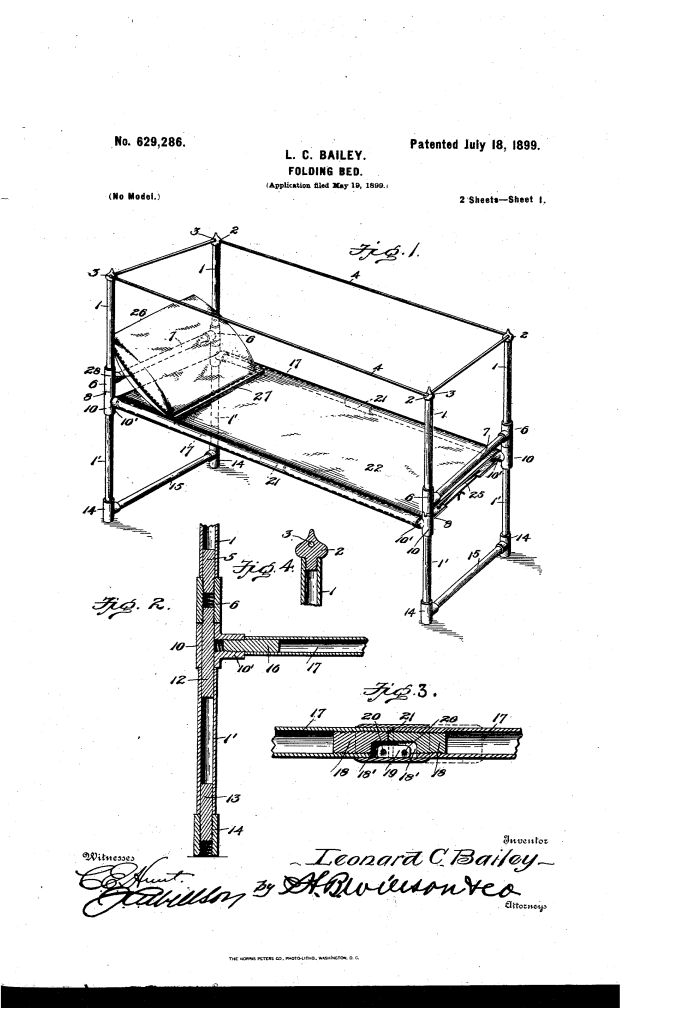

Folding Bed (Leonard C. Bailey, No. 629,286)

The patent by Leonard C. Bailey of Washington, D.C., describes a portable Folding Bed (Patent No. 629,286, 1899). The object is to provide a simple, inexpensive, convenient, and durable collapsible bed, primarily intended for hospital use due to its hygienic properties and the facility with which it can be cleaned, but also suitable for general use due to its compact transport size.

Inventor Background: Leonard C. Bailey

Leonard C. Bailey was an African-American inventor who contributed several patents in the late 19th century, including a compound suspension and a key contributor to Charles V. Richey’s Automatic Railroad Switch mechanism. His focus was often on modularity, robust mechanical joints, and utility, which is clearly demonstrated in this folding bed design.

Invention and Mechanism (Simplified)

The bed is a highly modular system of tubular metal parts designed to lock together rigidly when assembled and collapse quickly for storage.

- Modular Post Assembly (Head/Foot):

- Two-Part Posts: The head and foot posts are made of upper and lower tubular sections.

- Interlocking Couplings: These sections connect using T-couplings (6, 10) and threaded plugs (5, 12).

- Rigid Lock Joint (Key Innovation): The T-couplings have a tapering tongue (8) that fits into a corresponding recess (9). When screwed together, the tongue wedges into the recess.

- Function: This wedging action creates a rigid, non-wobbling joint that also automatically compensates for wear by allowing the parts to pull closer together.

- Collapsible Side Rails:

- Divided Rails (17): The side rails are divided transversely about midway of their length.

- Internal Hinge: The ends of the two rail sections are fitted with threaded sockets (18) and connected by a pivoted internal bar (19). This allows the two sections to fold parallel to each other when disassembled.

- Sleeve Lock (21): A sliding sleeve (21) fits snugly over the joint.

- Function: When the sleeve is slid over the hinged joint, it provides additional rigidity to the side rail, locking the two sections into a straight piece.

- Bed Bottom and Hygiene:

- Canvas Bottom: The bed bottom (23) is a canvas fabric with eyelets (24) and a lacing cord (25) to provide tension.

- Pillow Case (26): A pillow-case is permanently stitched to the bed bottom.

- Function: This integration of the pillow-case and canvas allows the entire assembly to be washed easily and quickly, making the bed suitable for hygienic use in hospitals or field settings.

Concepts Influenced by This Invention

Bailey’s folding bed influenced subsequent portable structures by pioneering wear-compensating, non-wobbling modular joints and sleeve-locked component rigidity.

- Wear-Compensating Modular Joints: The most significant influence is the tapering tongue-and-recess joint (8, 9). This design provides a pre-stressed, non-rotatable lock that automatically tightens against any lateral movement while compensating for metal wear, influencing the design of rigid, high-stress modular connections in modern scaffolding, shelving, and portable machinery.

- Sleeve-Locked Collapsible Structures: The use of an external sleeve (21) to slide over and lock a hinged or divided tubular member for temporary rigidity influenced the design of many modern camping tent poles, adjustable garment racks, and collapsible furniture .

- Integrated Utility and Hygiene: The permanent integration of the pillow-case (26) with the bed bottom to enhance hygiene and simplify cleaning influenced the design of modern field cots and medical beds, where the entire sleeping surface is often a single, cleanable component.

- Flat-Pack Portability: The entire design philosophy contributed to the engineering of flat-pack and highly portable furniture, emphasizing quick assembly and breakdown from minimal components.