🚁 Flying Machine (Walter G. Madison, No. 1,047,028)

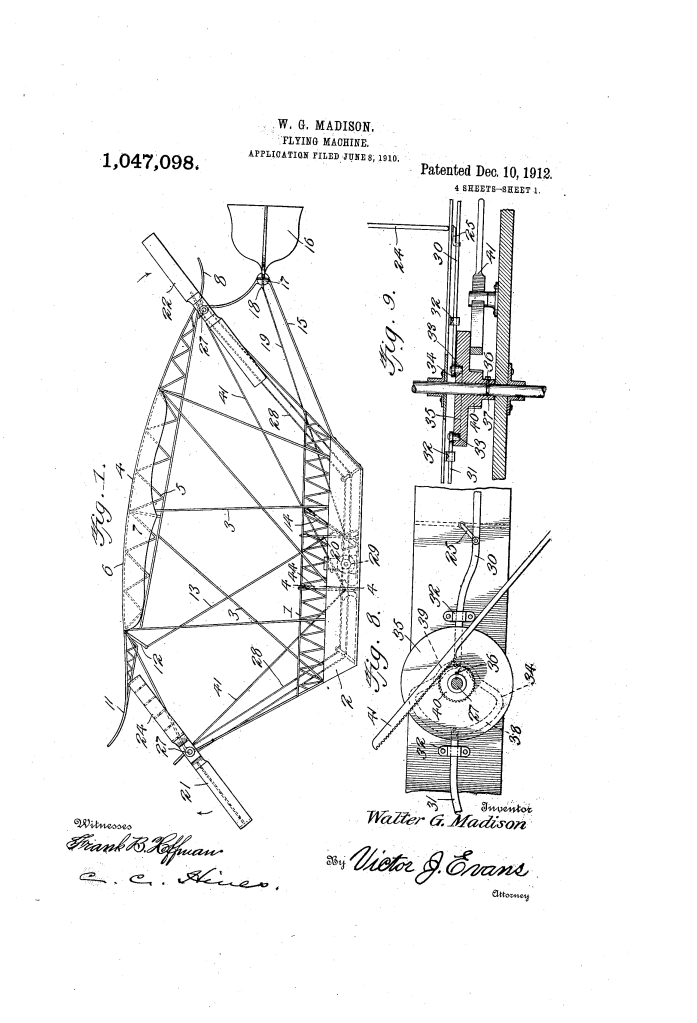

The patent by Walter G. Madison of Ames, Iowa, describes an advanced Flying Machine (Patent No. 1,047,028, 1912). This invention focuses on three primary aerospace challenges of the early 20th century: increasing stability, providing vertical and horizontal steering, and developing a propulsion system that could act as both a lifter (helicopter action) and a driver (airplane action).

Inventor Background: Walter G. Madison

Walter G. Madison was an African American inventor and contractor based in Iowa. His aviation patent, filed in 1910, demonstrates a sophisticated understanding of aerodynamics and mechanical control systems. While many contemporary inventors were struggling with basic flight, Madison was already designing “variable geometry” wings and “feathering” propellers—concepts that would not become standard for many years. His work reflects the high level of technical innovation coming from Black engineers during the pioneering era of flight.

Invention and Mechanism (Simplified)

Madison’s machine is a complex “bi-functional” craft, combining fixed-wing flotation with motorized vertical/horizontal thrust.

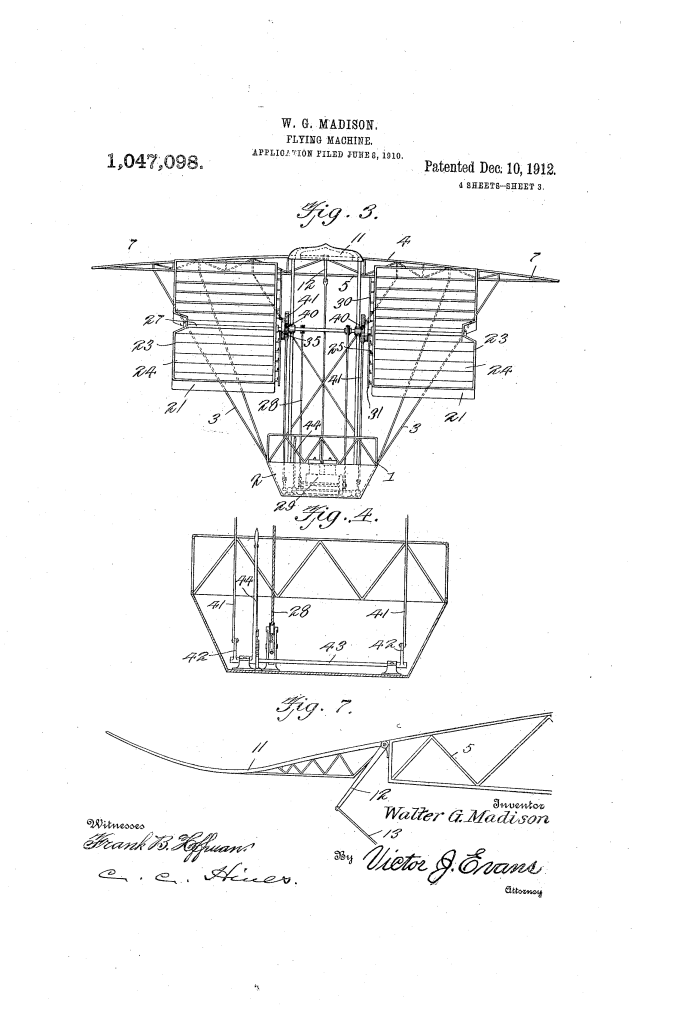

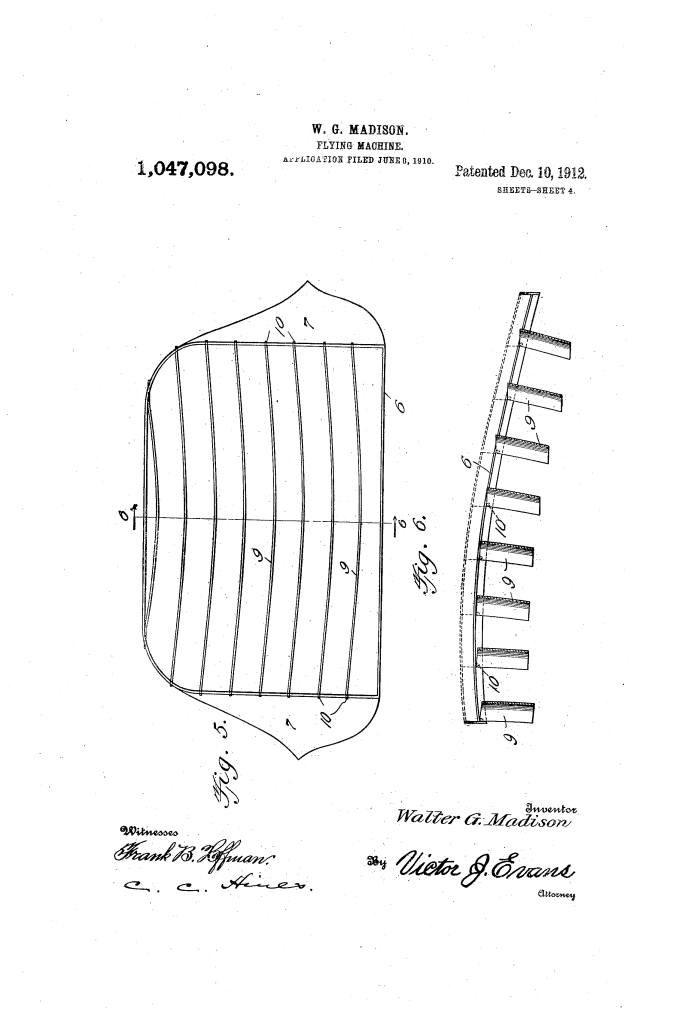

1. The Variable-Resistance Flotation Plane (4)

- The Frame (5/6): The main supporting wing or flotation plane (4) features a large rectangular opening in its center.

- Eccentric Slats (9): This central opening is filled with a series of vanes or slats (9) mounted on eccentric journals (10).

- Function (Ascent): When the machine is climbing vertically, the slats drop to a vertical position. This allows air to pass through the wing, reducing resistance so the craft can rise faster.

- Function (Flight/Descent): During forward flight or gliding, wind pressure pushes the slats up to a horizontal position, closing the wing and creating a solid surface for maximum lift.

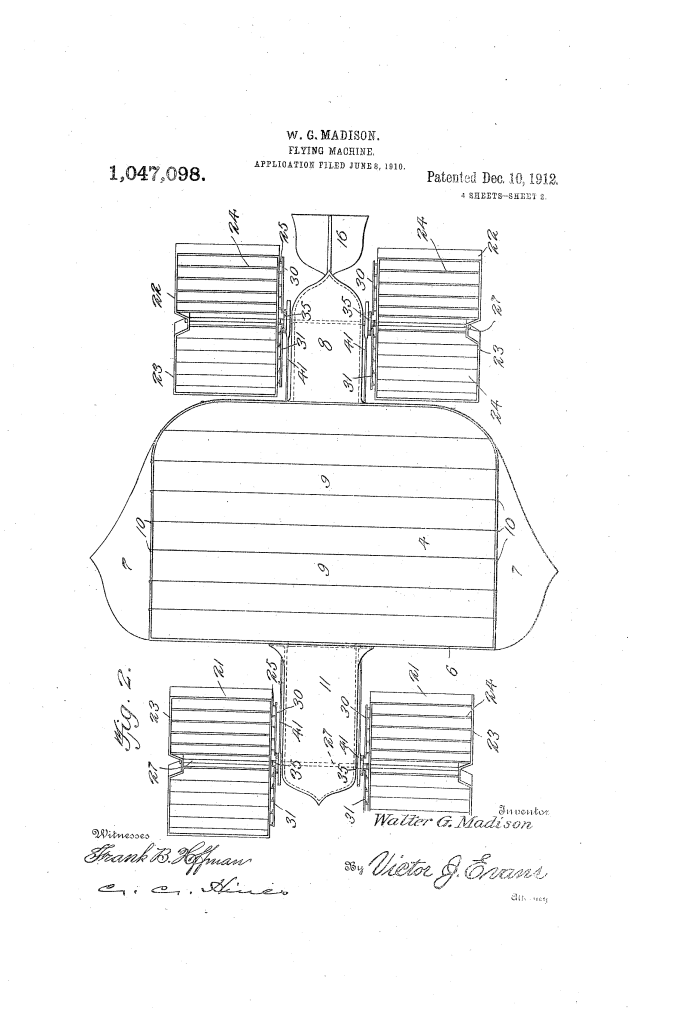

2. Feathering and Reversing Propellers (21, 22)

- Tandem Configuration: Four propellers are arranged at the corners of the machine.

- Vane-Bladed Frames (23/24): Each propeller consists of a frame with internal slats (24) rather than a solid blade.

- Cam-Driven Control (35): The angle of these slats is controlled by a cam or eccentric disk (35) with a groove (34).

- Function (Helicopter Lift): By shifting the cam using a controlling lever (44) and rack bars (36), the slats can be “feathered” to provide vertical lift alone, allowing the machine to rise straight off the ground.

- Function (Propulsion): The pilot can then shift the cam to change the “working blade” thrust, moving the craft forward.

3. Stabilization and Steering

- Stability Tips (7, 8): The wing includes fixed lateral tips (ailerons) and a rear tip to maintain equilibrium without pilot intervention.

- Dual Rudders: * Horizontal Rudder (11): At the front, used for vertical steering (climbing/diving).

- Vertical Rudder (16): At the rear, used for lateral steering (turning left/right).

Concepts Influenced by This Invention

Walter G. Madison’s flying machine influenced the development of vertical takeoff technology and dynamic aerodynamic control.

- Variable Wing Geometry: Madison’s “slatted wing” is a direct mechanical ancestor to modern wing slats and flaps, which allow aircraft to take off and land at lower speeds by changing the wing’s surface area and resistance.

- VTOL (Vertical Take-Off and Landing): The ability to shift propellers from “lift mode” to “drive mode” is the fundamental logic behind modern VTOL aircraft (like the V-22 Osprey or Harrier Jump Jet).

- Simultaneous Multi-Engine Control: The system for adjusting all four cam disks in unison using a single rock shaft (43) pioneered the centralized engine/thrust management systems used in multi-rotor craft today.

- Feathering Pitch Control: His use of cams to adjust propeller blade angles is a precursor to variable-pitch propellers, which are essential for maintaining engine efficiency across different altitudes and speeds.