Float-Operated Circuit-Closer (Mary H. Toland, No. 1,339,731)

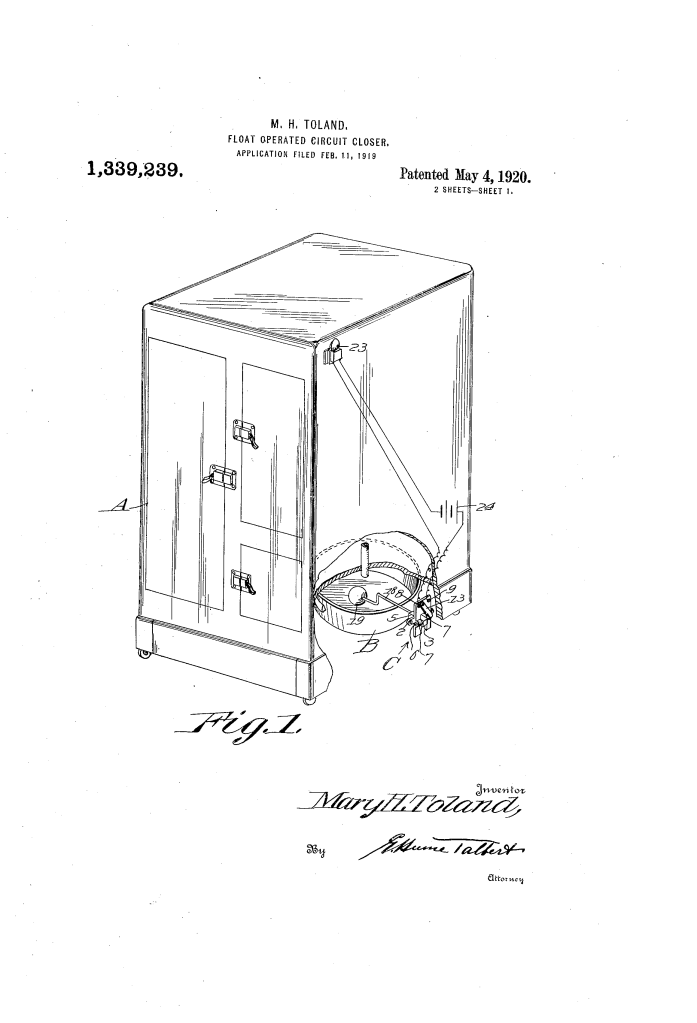

The patent by Mary H. Toland of Chattanooga, Tennessee, describes a Float-Operated Circuit-Closer (Patent No. 1,339,731, 1920). This invention is a specialized electrical alarm system designed for household refrigerators. In the early 20th century, refrigerators (often called “iceboxes”) relied on blocks of melting ice for cooling, which required a drip pan to catch the runoff. Toland’s device provided an automatic signal to warn the homeowner when the pan was nearly full, preventing messy overflows and floor damage.

Inventor Background: Mary H. Toland

Mary H. Toland was an African American inventor based in Chattanooga. Her 1920 patent addressed a very common domestic chore of the era. Before the advent of modern electric refrigeration with floor drains or automatic evaporation, emptying the “drip pan” was a daily necessity that was easily forgotten. Toland’s invention is a prime example of applied electrical engineering in the domestic sphere, demonstrating her ability to create a modular, adjustable device that could be retrofitted to any existing refrigerator.

Key Mechanical Components & Functions

The device consists of a base plate mounted to the side of the refrigerator, a pivoting arm with a float, and an electrical circuit.

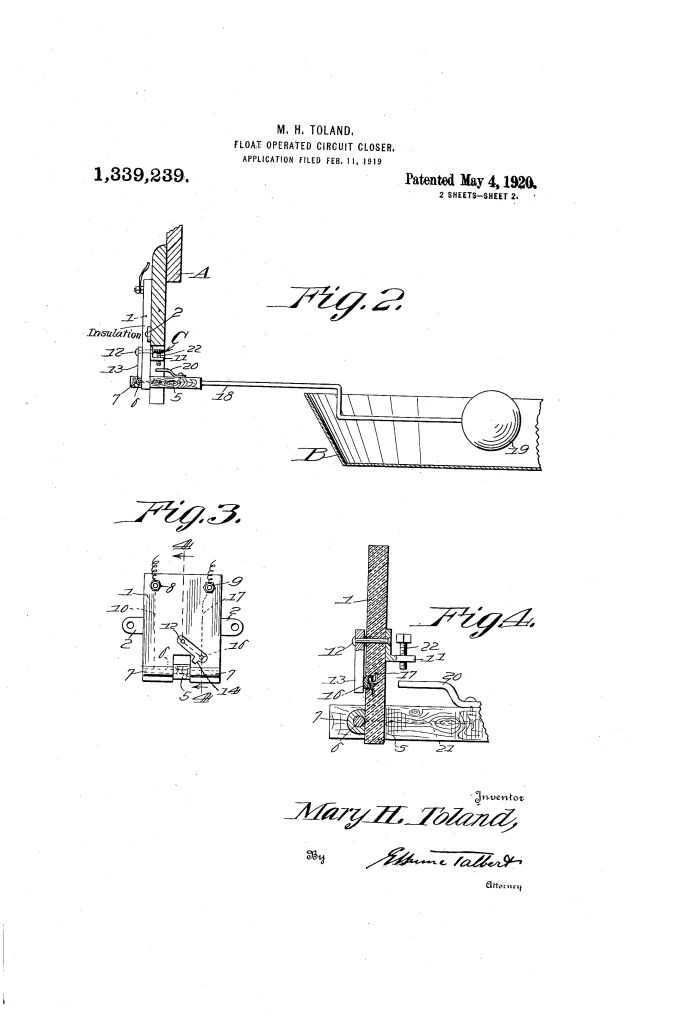

1. The Pivot Arm and Float (5, 18, 19)

- The Lever: An arm (5) is journaled in bearings (7) on an insulating base plate (1).

- The Float: One end of the arm projects behind the base plate and is connected to a stem (18) carrying a float (19).

- Function: The float sits inside the refrigerator’s drip pan. As the water level rises, the float lifts the rear end of the arm, causing the front end to pivot downward.

2. The Adjustable Contact System (20, 22)

- Spring Contact (20): Mounted on the upper edge of the arm is a spring contact member (20).

- Adjustable Screw (22): An L-shaped member (11) holds a screw (22) directly above the spring contact.

- Function: The screw acts as a terminal. Because it is threaded, it can be raised or lowered to adjust the “trigger point.” This allowed the device to work with drip pans of different depths—the homeowner could set the alarm to go off when the pan was half-full or nearly overflowing.

3. The Electrical Circuit (23, 24)

- The Alarm: The device is wired in series to a battery (24) and a bell (23) via binding posts (8, 9).

- Closing the Circuit: When the water reaches the predetermined level, the rising float pushes the spring contact (20) into the screw (22). This completes the circuit, causing the bell to ring until the pan is addressed.

4. The Multi-Function Pawl (13, 14) (Key Innovation)

Toland included a clever mechanical “override” to assist the user during maintenance.

- Projection (14): A rotatable pawl (13) features a small projection.

- Locking the Float: When the user is ready to remove the full pan, they can depress the front of the arm and slide the pawl over it.

- Function 1 (Mechanical): This locks the float in an elevated position, keeping it out of the way so the user can use both hands to slide the heavy pan out without snagging.

- Function 2 (Electrical): To prevent the bell from ringing while the pan is being emptied, the pawl is designed to slide off its contact point (16) when moved into the locking position. This automatically breaks the circuit and silences the alarm.

Improvements Over Manual Icebox Monitoring

| Feature | Manual Monitoring | Toland’s Circuit-Closer |

| Reliability | Requires constant visual checks; prone to forgetfulness. | Automatic audible alarm ensures the pan is never forgotten. |

| Adjustability | None. | Threaded screw (22) allows for precision “fill-level” settings. |

| Maintenance | Removing the pan can be awkward with a floating arm. | Pawl (13) locks the arm up and silences the bell simultaneously. |

| Versatility | Limited to specific refrigerator models. | Modular base plate (1) can be screwed onto any make of refrigerator. |

Significance to Domestic Engineering

Mary H. Toland’s circuit-closer influenced the development of liquid-level sensors and user-centered appliance design.

- The Fail-Safe Alarm: The logic of using a float to trigger a safety signal is a foundational principle in modern appliances, seen today in the overflow sensors of washing machines and dishwashers.

- Ergonomic Considerations: By including a locking mechanism that specifically freed up the user’s hands, Toland demonstrated an early understanding of human factors engineering—recognizing that the device must be helpful during the “correction” phase (emptying the pan), not just the “detection” phase.

- Circuit Interruption: The dual-purpose pawl (acting as both a mechanical lock and an electrical switch) is a sophisticated example of part consolidation, reducing the number of components while increasing the device’s utility.

- Modular Retrofitting: Her design anticipated the “aftermarket” supply industry, creating a safety feature that consumers could add to their existing appliances rather than needing to buy a new refrigerator.