Improvement in Fire-Escape Ladders (Joseph R. Winters, No. 214,224)

The patent by Joseph R. Winters of Chambersburg, Pennsylvania, describes an Improvement in Fire-Escape Ladders (Patent No. 214,224, 1879). This invention is a refinement of his earlier folding ladder (Patent No. 203,517), intended to make the apparatus more convenient and safer in use by introducing precise screw-and-gear mechanisms for vertical extension and inclination control.

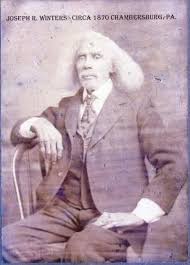

Inventor Background: Joseph R. Winters

Joseph R. Winters (1840-1916) was an African-American inventor and firefighter.

- Sustained Focus on Fire Safety: This 1879 patent is an important refinement of his initial 1878 invention. As a practical firefighter, Winters understood the shortcomings of his original design and sought to improve the mechanical control for speed and safety.

- The Problem Solver: Winters contributed a crucial, rapidly deployable apparatus for reaching the upper stories of burning buildings, making him a key figure in the history of aerial firefighting equipment.

Invention and Mechanism

The improved apparatus features two separate, gear-driven screw mechanisms with flywheels for controlled vertical extension and angular inclination.

1. Vertical Extension Mechanism (Lazy-Tongs Ladder)

- Ladder Type: The ladder (B) is a lazy-tongs (folding/extensible) type. The lower end of one bottom section is pivoted to a cross-bar (C).

- Screw Drive: The cross-bar (C) is fitted with a nut that receives a swiveled screw (D).

- Geared Actuation: A bevel-gear wheel (E) is attached to the screw (D) and meshes with a gear wheel (F) on a manual shaft (G).

- Flywheel Control: A heavy crank or crank-wheel (H) is attached to the shaft (G) to serve as a fly-wheel.

- Function: Turning the crank (H) rotates the screw (D), which moves the cross-bar (C) along the frame. This extends or folds the ladder (B). The flywheel (H) adds momentum and smoothness, making the extension and retraction safer and easier.

2. Inclination/Angle Adjustment Mechanism

- Ladder Base: The lower end of the other bottom section of the ladder is pivoted to a second cross-bar (I). This cross-bar slides up and down in vertical slots in vertical bars (J).

- Screw Drive: This second cross-bar (I) is fitted with nuts (K) that fit upon a set of swiveled screws (L).

- Geared Actuation and Flywheel: The screws (L) are driven by bevel-gear wheels (N, O) connected to a manual shaft (P), which also has a heavy crank or crank-wheel (Q) acting as a flywheel.

- Function: Turning the crank (Q) raises or lowers the second cross-bar (I). Because this cross-bar moves vertically relative to the fixed pivot of the first section, it adjusts the angle or inclination of the entire extended ladder.

3. Hose Attachment

- Hose Drum (R): A drum is pivoted to the middle of the frame (A) and has a crank (S). A hose (T) is attached to the drum.

- Attachment Hook: The nozzle (U) of the hose (T) has a hook () to be attached to a round of the ladder, ensuring the hose is carried up with the ladder for rapid deployment.

Concepts Influenced by This Invention

Winters’s refined ladder system influenced subsequent mechanical designs by integrating precision controls and momentum stabilization into a single mobile apparatus.

- Dual-Axis Precision Control: The use of two independent, screw-driven mechanisms to control the main functions (vertical height and angular inclination) influenced the design of modern aerial rescue platforms and mobile cranes . This provides operators with necessary fine-tuning for accurate positioning.

- Flywheel for Actuator Stabilization: The inclusion of heavy cranks/flywheels (H, Q) on the input shafts influenced the design of manual machinery. The flywheel’s momentum smooths the operation, prevents sudden drops, and reduces the jerky, high-force input required from the operator, thereby increasing safety and convenience.

- Screw-Driven Linear Actuation: The conversion of rotary input (crank) into controlled linear movement (via screw D moving cross-bar C) is the basis of modern lead screw and ball screw actuators used for precision positioning in machinery, robotics, and industrial lifts.

- Hose Management Systems: The integrated drum (R) and the hook (

) on the nozzle for simultaneous deployment of the hose and ladder influenced modern designs for firefighting aerials that feature integrated, self-laying water lines.