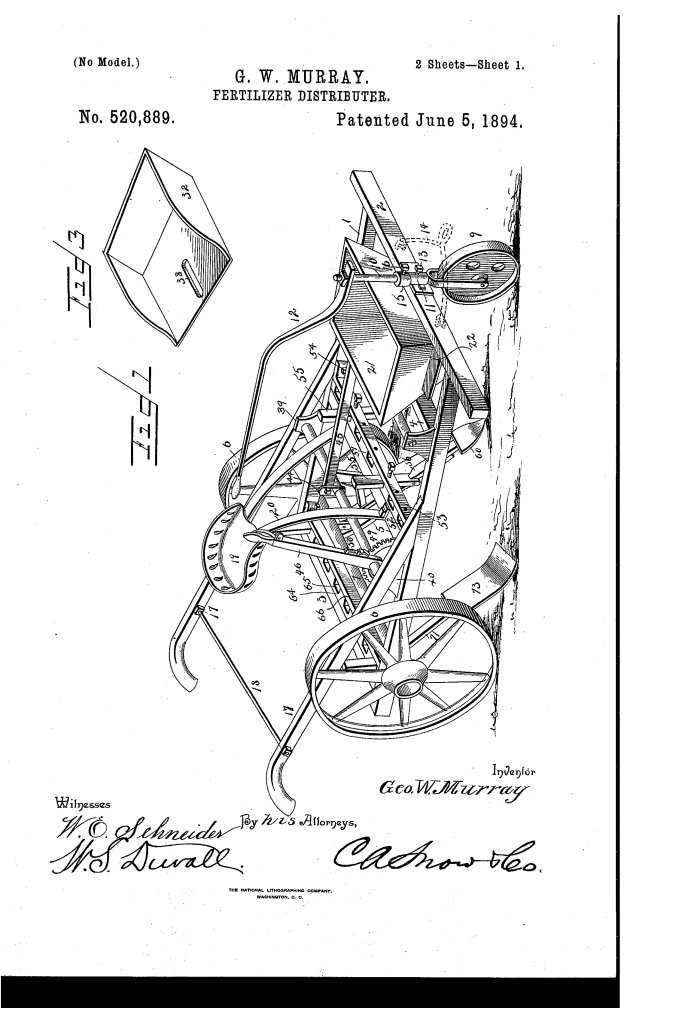

Fertilizer-Distributer (George W. Murray, No. 520,889)

The patent by George W. Murray of Rembert, South Carolina, describes a Fertilizer-Distributer machine designed to evenly drill any fertilizing agent and then immediately cover the drilled furrows. The goal was to create a cheap, simple, and durable machine that could prepare a uniform bed of fertilized soil.

Invention and Mechanism

The machine is a wheeled, human-operated frame that integrates the fertilizer distribution mechanism with a two-stage soil-working system.

1. Fertilizer Distributing Mechanism

- Hopper (21): A container for the fertilizer, located at the front of the machine. It has a sliding cut-off (22) to regulate discharge.

- Crank-Shaft Drive: A transverse crank-shaft (24) is journaled in V-shaped hangers (23). Motion is conveyed from the main axle (7) via a sprocket-chain (26) to a sprocket-wheel (25) on the crank-shaft.

- Vibratory Distributing Shoe (32): Located beneath the hopper’s discharge end. A slotted standard (29), pivoted to the shoe (32), receives the crank (27) of the shaft (24).

- Function: As the shaft (24) rotates, the crank (27) engages the slotted standard (29), causing the distributing shoe (32) to vibrate or reciprocate in a short, jerky manner. This vibration evenly distributes the fertilizer as the machine moves.

- Adjustment: A rearward adjusting-rod (35), mounted in a threaded eye (34), connects to the back of the shoe (32). By turning this rod, the operator can regulate the vibrations of the shoe, controlling the amount of fertilizer distributed at each pass.

2. Two-Stage Soil Working (Shovels)

The machine uses two sets of vertically and laterally adjustable shovels, controlled by a single lever system, to prepare the soil and cover the fertilizer.

- Front Shovels (60) – Opening/Mixing:

- Function: These shovels take at opposite sides of the path, traveling slightly in advance of the shoe (32). They turn the soil over to receive the fertilizer.

- Rear Shovels (73) – Covering/Bedding:

- Function: These shovels follow the front set (60). They are shaped to throw the soil inwardly toward the center, mixing the fertilizer with the soil and forming the final fertilized bed or ridge.

3. Common Control System

- Rock-Shaft Linkage: Both the front (60) and rear (73) shovels are linked to a synchronized system of front (41) and rear (42) rock-shafts by connecting-bar (45) and various adjustable hangers.

- Operating Lever (46): A single hand-lever (46) attached to the rear rock-shaft (42) allows the operator to raise or lower both sets of shovels simultaneously out of or into the ground and lock them at the desired depth using a segmental standard (49).

- Adjustability: Both the front and rear shovels (60, 73) are laterally adjustable by moving their standards into different vertical recesses (52, 65) in their respective cross-bars, allowing the width of the final fertilizer bed to be changed.

Historical Significance and the Inventor

This Fertilizer-Distributer (1894) is another key invention by George W. Murray, the African-American innovator from South Carolina. It addresses the third core need of the planting process, following his chopper and general planter designs.

- Critical Role of Fertilization: In post-Reconstruction cotton agriculture, the use of commercial fertilizer became essential to maximize yields on depleted Southern soils. The effectiveness of fertilizer depended heavily on even distribution and proper incorporation into the soil.

- Efficiency and Accuracy: Murray’s machine solved the problem of manual distribution, which was uneven and wasteful. The vibratory shoe (32) provided a controlled, uniform drill of the agent, and the integrated two-stage covering process ensured the fertilizer was properly mixed and covered, making the application accurate and efficient.

- Systemic Farming: This patent, combined with his others, shows Murray’s vision for a complete mechanized farming system. A farmer could use his stalk-knocker/furrow-opener, then his fertilizer-distributer, and finally his planter (all patented in 1894) to manage every step of the row-crop process efficiently.

Relation to Current Items

Murray’s distributer employs principles fundamental to modern agricultural chemical application:

- Vibratory/Oscillating Feeds: The use of a vibratory shoe (32) driven by a crank to ensure a constant, uniform flow of material is the precursor to modern oscillating or shaker-style fertilizer/seed distributors and chemical metering systems that rely on mechanical agitation to prevent clumping and achieve accurate broadcast or row application.

- Metering Adjustment: The threaded adjusting-rod (35) to change the vibration and control the rate of fertilizer output is an early, mechanical version of the rate control mechanism on modern precision chemical spreaders, which use electronic valves and sensors to adjust the material flow based on pre-set VRT (Variable Rate Technology) maps.

- Integrated Bed Formation: The sequential use of the front shovels (60) to open/mix and the rear shovels (73) to cover/hill is the direct antecedent of modern sub-surface banding applicators and tillage toolbars that simultaneously inject fertilizer and rebuild the soil bed over the application zone.