🌾 Feed-Rack (Dennis W. Shorter, No. 363,089)

The patent by Dennis W. Shorter of Atchison, Kansas, describes an improved Feed-Rack (Patent No. 363,089, 1887). This invention is a specialized agricultural structure designed for feeding livestock, such as cattle or sheep. Shorter’s primary goal was to create a rack that prevented the wasting of hay or grain while ensuring that the livestock could feed easily without crowding or injuring one another.

Inventor Background: Dennis W. Shorter

Dennis W. Shorter was an African American inventor based in Kansas during the late 19th century. His work focused on practical, durable solutions for the farming community. During this era, livestock management was shifting toward more efficient, organized feeding methods to maximize yield and reduce labor. Shorter’s feed-rack is a prime example of “vernacular engineering”—utilizing accessible materials like wood and iron to create a highly functional, modular system that solved common problems on a working ranch.

Invention and Mechanism (Simplified)

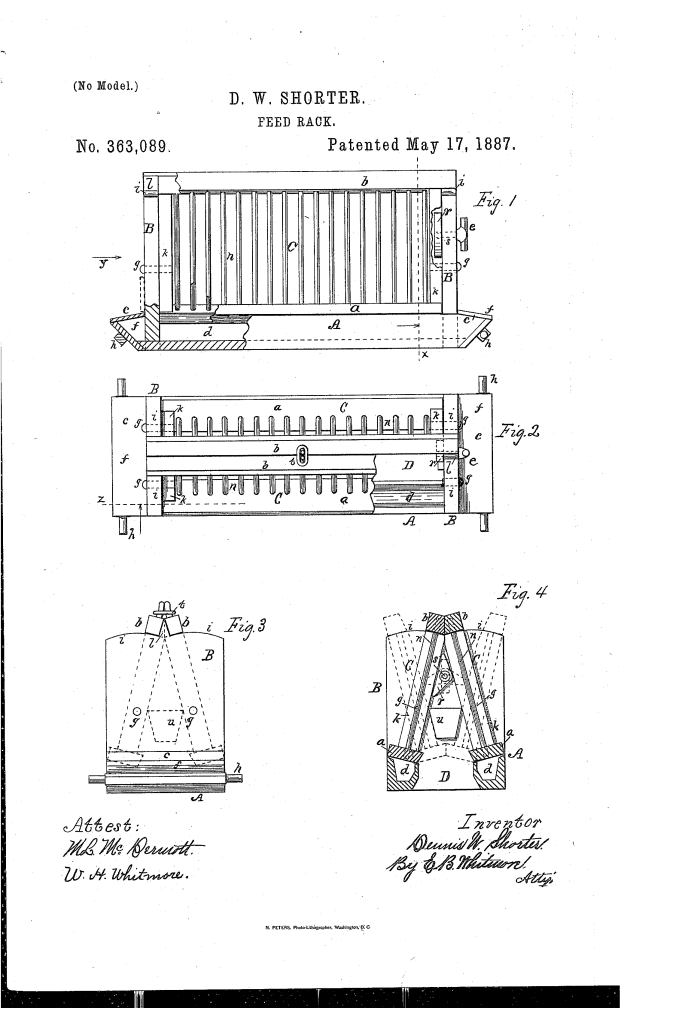

The feed-rack is designed as a sturdy, ventilated container that manages the distribution of fodder through gravity and specific spacing.

1. The Slatted Construction

- Design: The rack is built with a series of vertical or slightly inclined slats or bars.

- Function: These slats are spaced specifically to allow animals to reach the hay with their mouths but prevent them from pulling out large, wasteful clumps that would end up on the ground to be trampled.

2. The Trough and Grain-Box (Key Innovation)

- Base Structure: At the bottom of the slatted rack, Shorter included a trough or grain-box.

- Function: Any small bits of hay or seeds that fall through the slats are caught in the trough rather than falling into the dirt. This area can also be used to provide supplemental grain, making it a dual-purpose feeding station.

3. Gravity-Fed Hopper System

- Inclined Sides: The internal walls of the rack are often angled to form a V-shape or hopper.

- Function: As the animals eat the hay from the bottom, the remaining fodder naturally slides down to the openings. This ensures a constant supply of food is available at the “front line” of the rack without requiring the farmer to manually redistribute the hay.

4. Weather Protection and Durability

- The Roof: Shorter designed the rack with an overhanging roof or cover.

- Function: This protects the fodder from rain and snow, preventing rot and ensuring the feed stays palatable for the animals. The entire structure is mounted on heavy runners or “skids,” allowing it to be easily moved across a pasture by a team of horses.

Improvements Over Existing Designs

| Feature | Standard 1880s Racks | Shorter’s Feed-Rack |

| Waste Reduction | Open piles or simple bins led to 30%+ waste. | Slats and troughs catch “fallout” and prevent trampling. |

| Feeding Access | Animals often crowded and fought at the corners. | Uniform slat spacing encourages a linear feeding arrangement. |

| Portability | Rigid, permanent structures. | Mounted on runners for easy relocation to prevent soil erosion. |

| Feed Preservation | Exposed to the elements. | Integrated roof keeps hay dry and fresh. |

Significance to Agricultural Engineering

Dennis W. Shorter’s feed-rack influenced the design of modern livestock equipment and sustainable farm management.

- Standardization of Feeding Gaps: Shorter’s focus on the precise spacing of slats contributed to the understanding of animal ergonomics, leading to the standardized “head-gates” and “stanchions” used in modern dairy and beef farming.

- Nutrient Conservation: By preventing fodder from touching the ground, the rack significantly reduced the spread of soil-borne parasites and diseases among the herd.

- Efficient Pasture Rotation: The portable nature of the rack allowed farmers to move the feeding site frequently, a precursor to modern rotational grazing techniques that protect soil health and promote even fertilization of the land.