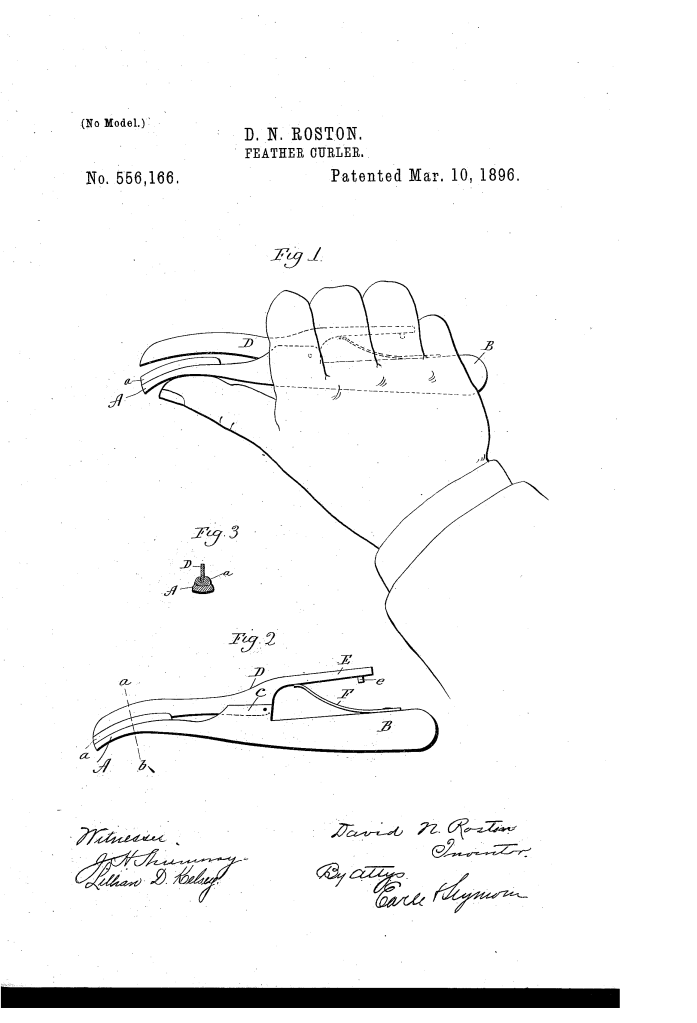

Feather-Curler (David N. Boston, No. 556,166)

The patent by David N. Boston of New Haven, Connecticut, describes an improved Feather-Curler (Patent No. 556,166, 1896). The object of the invention is to create a mechanical device that guards the user’s thumb while providing a precise, easy-to-operate mechanism for curling feather flues, imitating the standard hand method.

Invention and Mechanism

The device is a spring-loaded, hand-held clamp that uses a cushioned surface and a curved blade to impart curl.

- Guard and Cushion (The “Thumb”):

- Curved Guard Member (): This member has a handle (B) at one end. Its curvature is designed to correspond to the natural curvature of the inside of the end of the thumb.

- Cushion (): A cushion of rubber or other suitable material is applied to the face of the guard (

). This cushion is formed with a longitudinal groove ().

- Function: The cushion (

) yields “like the flesh of the thumb,” and the guard protects the thumb from the pressure required for curling.

- Blade and Curler:

- Blade (D): An outwardly-curved blade pivoted between trunnions (C) at the inner end of the guard member (

).

- Alignment: The blade (D) is curved to correspond with the cushion (

) and its edge is adapted to be entered into the groove () in the cushion.

- Blade (D): An outwardly-curved blade pivoted between trunnions (C) at the inner end of the guard member (

- Spring-Actuated Operation (Key Innovation):

- Tail (E): The rear end of the blade extends rearward over the handle (B).

- Spring (F): A spring is arranged between the handle (B) and the tail (E) of the blade.

- Function: The spring (F) is arranged to force the blade end downward against the guard/cushion, applying the necessary pressure automatically. The user only needs to press down on the tail (E) to open the clamp to receive the feather flues. The feather flue is then drawn between the cushion and the blade, where the pressure curls it.

Historical Significance and the Inventor

David N. Boston’s 1896 patent is a consumer gadget targeting the major fashion trends of the Victorian and Edwardian eras.

- Feathers in Fashion: During this period, elaborately curled plumes and feathers were an immensely popular accessory for women’s hats and clothing. The process of curling was time-consuming and tedious when done manually.

- Ergonomic Improvement: The invention directly addressed the problem of “thumb injury” and fatigue caused by the high pressure required for traditional manual curling. By providing a cushioned guard and using a spring to apply the pressure, Boston mechanized the force required, speeding up the process and making it accessible to amateur curlers.

- Mechanizing a Craft Technique: The device is a clever example of engineers analyzing a manual craft technique (drawing the feather between a hard edge and a yielding surface) and replicating it precisely using a mechanical tool.

Core Concepts Utilized Today

The feather curler employs simple, effective mechanical principles common in modern tools that require applied pressure and ergonomic grips.

- Spring-Loaded Clamping Tools: The design of using a spring to automatically maintain a set pressure, requiring the user only to apply force to release or open the device, is the basis for all modern spring clamps, clipping tools, and handheld staplers .

- Cushioned Contact Surfaces: The use of a rubber cushion against a rigid blade to protect the material (or the user) and ensure a yielding, conforming contact surface is a feature of many modern finishing and gripping tools, such as specialty pliers, crimping tools, and ergonomic grips.

- Leverage for Pressure: The long tail (E) over the handle (B) acts as a lever arm. Pushing down on the tail applies a magnified force to the blade tip, a fundamental principle of mechanical advantage used in household nutcrackers, shears, and specialized tools.