✉️ Envelop-Moistener (James M. Brooks, No. 1,092,763)

The patent by James M. Brooks of Washington, D.C., describes an improved Envelop-Moistener (Patent No. 1,092,763, 1914). This invention was designed to automate and simplify the process of wetting the gummed flaps of envelopes. Unlike the messy sponges or small rollers common in the early 20th century, Brooks’s device utilized a vertical gravity-fed system and a resilient guide to ensure that moisture was distributed perfectly and evenly across the entire flap in a single motion.

Inventor Background: James M. Brooks

James M. Brooks was an African American inventor based in the District of Columbia. His device, patented in 1914, reflects a practical response to the high volume of correspondence in professional and government offices. Before the widespread use of electric sealing machines, moistening hundreds of “long” envelopes (legal or business size) was a tedious, manual task. Brooks, likely observing this inefficiency in the clerical environment of Washington, D.C., engineered a solution that prioritized uniform pressure and controlled flow, demonstrating a keen understanding of fluid dynamics and mechanical tension.

Invention and Mechanism (Simplified)

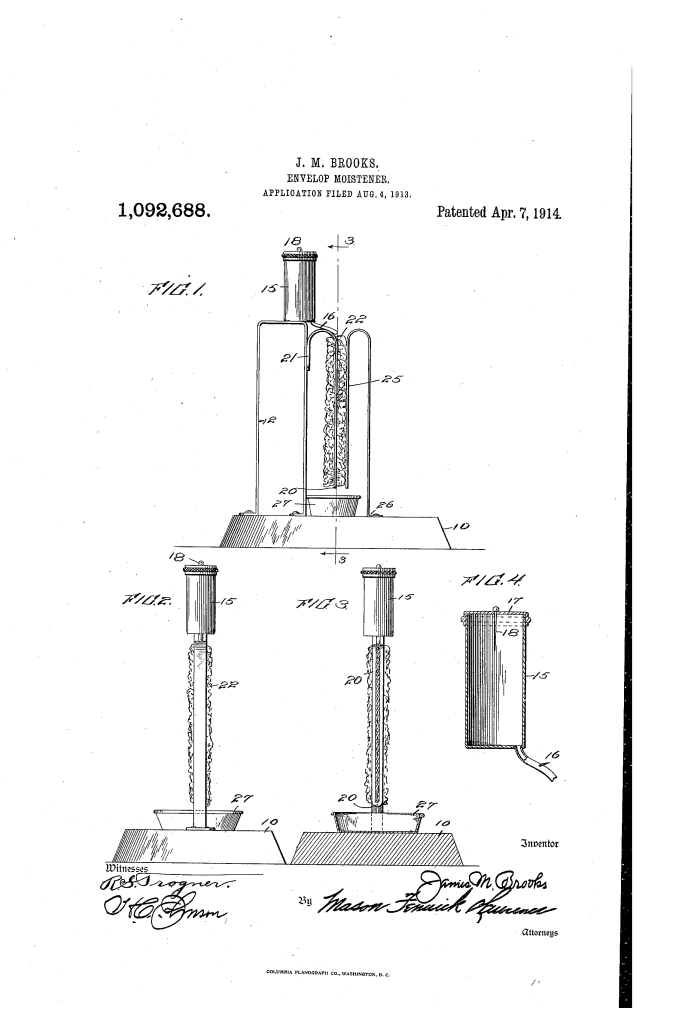

The device consists of a vertical stand with a water reservoir at the top and an absorbent strip through which the envelope flap is pulled.

1. The Regulated Water Supply (15, 18)

- The Reservoir (15): A water tank is mounted at the top of a U-shaped support (12).

- The Control Pin (18): Inside the tank is a tapered pin (18) passing through a cap.

- Function: By lifting the pin, the user admits air into the tank, which regulates how much water flows down through the outlet pipe (16). This prevents the absorbent material from becoming oversaturated and dripping.

2. The Vertical Absorbent Strip (20, 22)

- Slotted Member (20): A metallic strip with a vertical slot holds the absorbent material (22)—typically a strip of sponge—in a vertical position.

- Vertical Orientation: Brooks specifically chose to orient the sponge vertically and make it roughly the length of a business envelope. This allows gravity to assist in moving water from the top to the bottom of the strip, ensuring the entire length remains moist.

3. The Resilient Guide Strip (25) (Key Innovation)

- Uniform Pressure: A strip of resilient metal (25) is bent into a U-form and mounted to the base. One side of this U-strip presses against the moistened sponge.

- Function: As the user draws an envelope flap downward between the sponge and the metal strip, the resiliency of the metal exerts even pressure against the gummed surface. This ensures the entire flap is moistened without the user having to press manually or risk tearing the paper.

4. Surplus Management (27)

- Catch Basin (27): At the bottom of the device is a receptacle (27).

- Function: Any excess water that gravity pulls through the sponge is caught here, keeping the desk surface clean and dry.

Concepts Influenced by This Invention

James M. Brooks’s moistener influenced the development of office automation and fluid application tools.

- Gravity-Fed Distribution: The use of a vertical wick or sponge fed from a top-mounted reservoir is a principle used in various modern labeling machines and stamp moisteners.

- Resilient Pressure Guides: The logic of using a spring-tempered metal guide to hold a workpiece against a treatment surface (in this case, the sponge) is a fundamental engineering concept found in modern laminators, printers, and industrial coating machines.

- Flow Control via Air Induction: Brooks’s tapered pin ($18$) is an early mechanical version of a flow-control valve, demonstrating how air displacement can be used to manage liquid discharge in small appliances.

- Modular Absorbent Systems: By using a slotted metal frame to compress and hold a sponge strip, Brooks pioneered the “replaceable cartridge” approach for office supplies, allowing users to easily swap out old or dirty sponges.