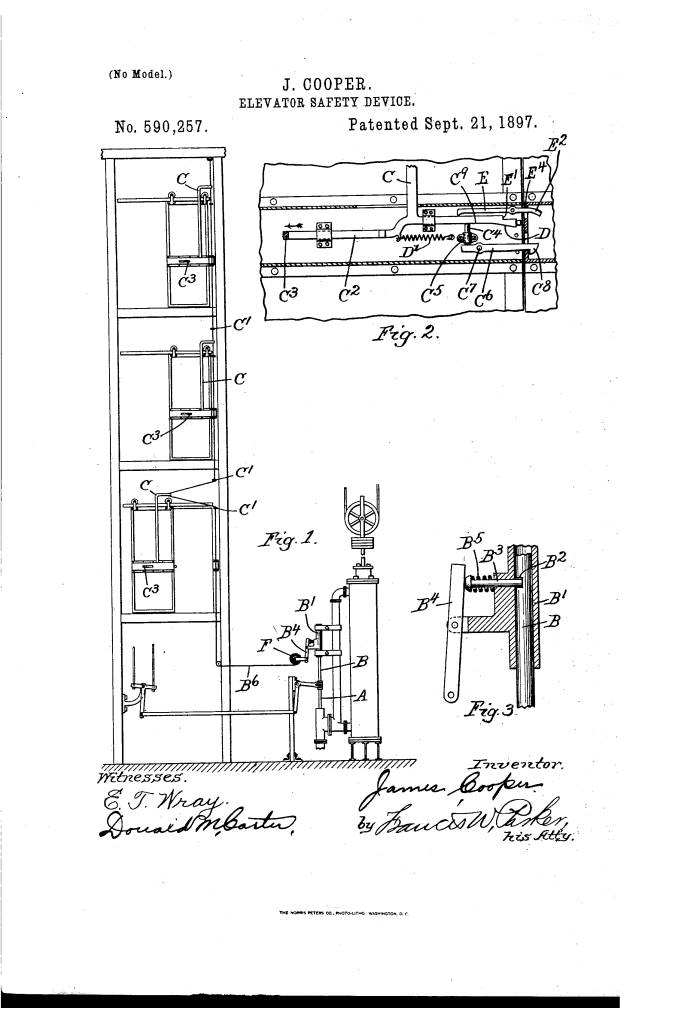

Elevator Safety Device (James Cooper, No. 590,257)

The patent by James Cooper of Chicago, Illinois, describes an improved Elevator Safety Device (Patent No. 590,257, 1897). The primary object is to ensure the elevator motor mechanism is locked against motion before the door becomes unlocked, making it impossible to open the door while the car is in motion or before the car is safely immobilized.

Inventor Background: James Cooper

James Cooper was an inventor focused on essential safety and interlocking mechanisms for early urban infrastructure. He also patented a previous elevator safety device (No. 536,605, 1895). His work addressed the critical safety need in the late 19th-century elevator industry: preventing catastrophic accidents caused by operators starting the car before the door was closed. Cooper consistently applied robust mechanical solutions to create fail-safe interlocking systems.

Invention and Mechanism

The device is a sophisticated mechanical interlock that integrates the door’s latch release with the motor’s control lock via a short-stroke/long-stroke cable system.

1. Motor Locking Mechanism

- Valve Rod (A/B): The rod (B) is connected to the motor’s control mechanism (valve rod A). It is the moving element that controls the motor.

- Notch (): A single notch in the rod (B), positioned so that a pin (

) can only enter it when the motor mechanism is stationary (valve closed).

- Locking Pin (): A pin that is normally held disengaged by a spring (

).

- Function: When the pin enters the notch, it locks the rod (B), preventing the car from starting.

2. Door Control and Latch

- Movable Part (): A sliding piece attached to the door, moved by the elevator operator (the “elevator-boy”).

- Door Latch (): The door is held shut by a latch (

).

- Latch Release (D): The sliding piece (

) is beveled at the end (D). This bevel engages a pin (

) connected to the latch (

). Movement of the bevel (D) forces the pin () down and raises the latch (), unlocking the door.

3. Safety Interlock (Key Innovation: Sequential Action)

- Power-Transmitting Device (): A cord connects the locking lever (

) (which controls the locking pin

) to an arm (C) on the sliding door piece (

).

- Coil Spring (F): A coil spring is intentionally interposed between the door’s movable part (

) and the pin (

), allowing for a short-stroke/long-stroke differential.

- Sequential Operation: When the operator pulls the door’s sliding piece (

):

- Lock First (Short Stroke): The initial, small movement of the sliding piece (

) pulls the cord (

) and lever (

), forcing the pin () into the notch (

), locking the motor. This occurs before the bevel (D) engages the latch pin (

).

- Unlock Door (Long Stroke): The continuing movement of the sliding piece compresses the coil spring (F) and finally allows the bevel (D) to engage the latch pin (

), unlocking the door.

- Result: The motor is guaranteed to be locked stationary before the door can open.

- Lock First (Short Stroke): The initial, small movement of the sliding piece (

4. Door Retention and Reset

- Holding Pawl (E): A pawl engages a notch (

) on the sliding piece (

) to hold the piece in its retracted (unlocked door) position. The pawl automatically releases when the door is returned to the closed position.

Concepts Influenced by This Invention

Cooper’s design influenced subsequent safety systems by pioneering the positive sequential interlock needed for critical human-machine interfaces.

- Sequential Safety Interlocks: The core concept of a multi-stage, time-delayed actuation where the safety function (Motor Lock) engages first, and the operational function (Door Unlocks) engages second, influenced the design of:

- Industrial Machine Guarding: Systems where the power must be disabled before a protective guard can be opened (often achieved today with sequenced electrical switches).

- Access Control Airlocks: Systems that require one door to lock before the other can unlock.

- Motion Differential Linkage (Short/Long Stroke): The use of a spring (F) in the linkage to create a controlled differential between a short, critical safety action and a long, logistical action influenced the design of mechanical systems that convert a large user input (door pull) into a small, precise mechanical output (pin movement).

- Fail-Safe Locking: The system’s reliance on the pin (

) only being able to enter the notch (

) when the system is already stationary ensures a fail-safe rest condition, a foundational principle in all critical elevator safety systems.