🛗 Elevator (Alexander Miles, No. 371,207)

The patent by Alexander Miles of Duluth, Minnesota, describes significant improvements in Elevator technology (Patent No. 371,207, 1887). The invention addresses two critical safety and efficiency issues of the era: the danger of open elevator shafts and the manual labor required to operate cage doors. Miles developed a system that automatically closes shaft openings and provides a mechanism to automatically open and close cage doors at the operator’s command.

Inventor Background: Alexander Miles

Alexander Miles (1838–1918) was a prominent African-American inventor and businessman. Before his success in Duluth, he worked as a barber in Wisconsin and later moved to Minnesota, where he operated a successful real estate and insurance business. His invention was inspired by the dangerous reality of 19th-century elevators, which required passengers or operators to manually close heavy shaft doors; failures to do so often resulted in fatal falls. Miles’s patent was a landmark in safety engineering, and while he did not invent the elevator itself, his “automatic” features became a standard for the industry.

Invention and Mechanism (Simplified)

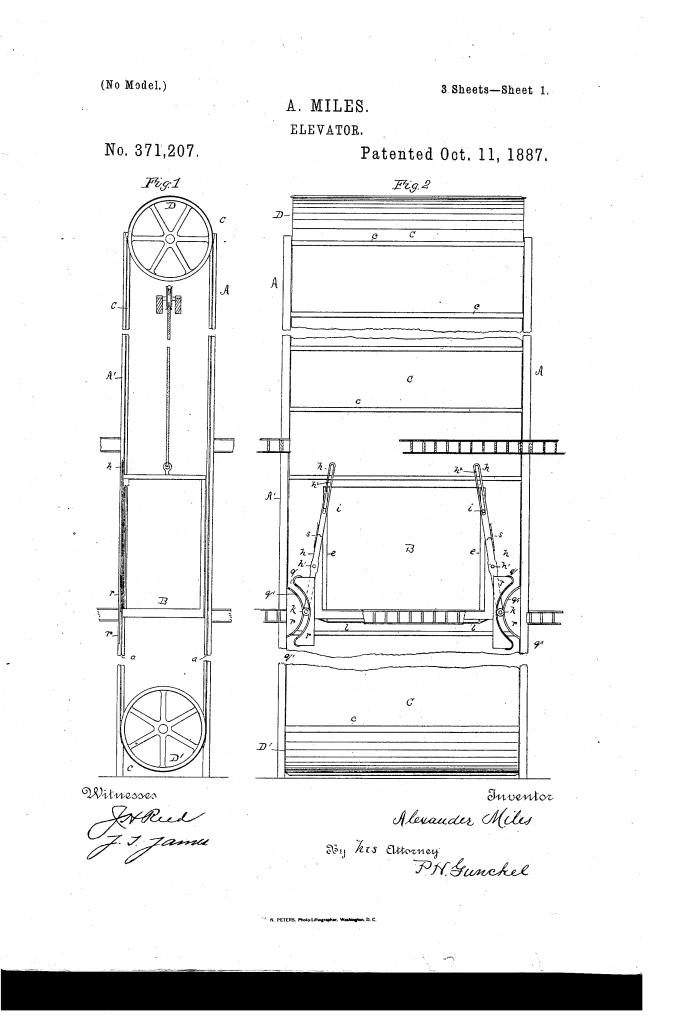

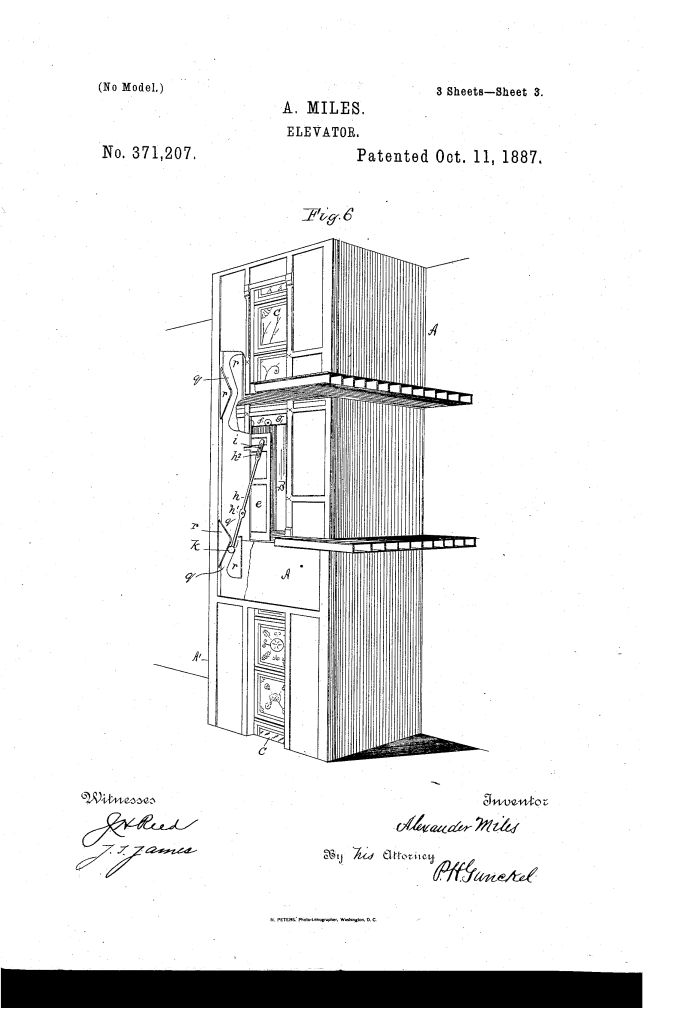

Miles’s design utilizes a flexible belt to keep the shaft secure and a lever-and-roller system to handle the doors.

1. Automatic Shaft Enclosure (The Protective Belt)

- Flexible Belt (B): A long belt has its ends attached to the top and bottom of the elevator cage. This belt runs over drums (D) at the very top and bottom of the elevator shaft.

- Function: As the cage moves, the belt moves with it. The belt acts as a moving wall that blocks all floor openings except the one where the cage is currently positioned. This prevents anyone from accidentally falling into the shaft when the elevator is on a different floor.

- Guide Strips (C): Cross-strips on the belt slide in grooves (a) in the shaft’s uprights to keep the fabric taut and properly aligned.

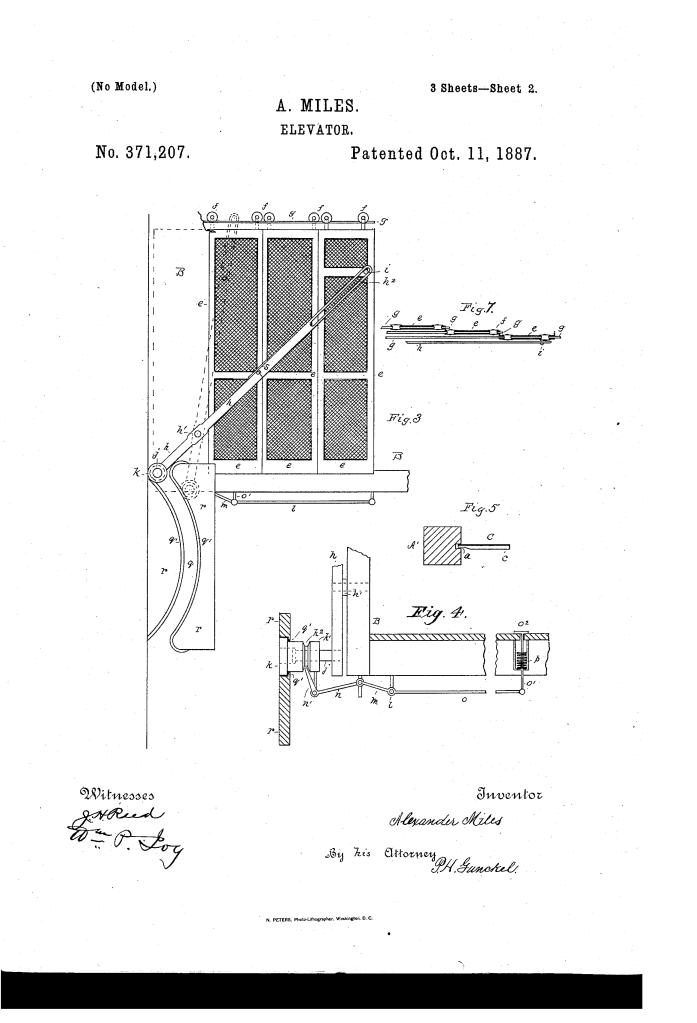

2. Automatic Cage Door Operation (Key Innovation)

- Sliding Door Sections (c): The cage doors are made of multiple sections that slide past each other on separate tracks (g). This allows for a wide opening even in a small cage.

- Levers (h) and Roller-Wheels (k): Levers are attached to the doors at one end and carry roller-wheels (k) at the other.

- Curved Grooves (q): Plates with curved ways or grooves (q) are fixed at each floor inside the shaft.

- Function: As the cage approaches a floor, the rollers follow the curve of these grooves. The shape of the curve forces the levers to swing, which slides the doors open automatically as the cage reaches the level of the building floor.

3. Operator Control (The Foot Pedal)

- Rock-Shaft (l) and Lever (o): The operator can choose whether or not to open the doors at a specific floor.

- Function: By stepping on a foot-piece (o”), the operator shifts the rollers (k) outward on their spindles. Only when shifted outward do the rollers engage with the curved grooves in the shaft. If the operator does not press the pedal, the rollers stay retracted, and the doors remain closed as the cage passes the floor.

4. Safety Hinge

- Spring-Backed Levers: The levers (h) are hinged and backed by springs (s).

- Function: If a person or object is caught in the closing doors, the springs allow the levers to yield, preventing injury or mechanical breakage.

Concepts Influenced by This Invention

Alexander Miles’s elevator improvements influenced the evolution of high-rise safety and automated transit.

- Automatic Door Logic: The core concept of synchronizing the movement of the vehicle (the cage) with the movement of its barriers (the doors) is a fundamental principle in all modern elevators and mass transit systems (like subway platform doors).

- Fail-Safe Shaft Protection: The use of a “moving wall” (the belt) to protect the shaft influenced the development of telescoping shaft shields and the modern interlock systems that prevent floor doors from opening unless a cage is present.

- Mechanical Cam-Driven Automation: The use of curved ways (cams) to translate vertical machine movement into horizontal door movement is a classic engineering solution still found in various types of automated machinery and packaging equipment.

- Human-Machine Interface (HMI): By integrating a foot-operated selector, Miles demonstrated an early mastery of allowing a human to “program” a mechanical automation on the fly, a precursor to modern electronic floor selection.