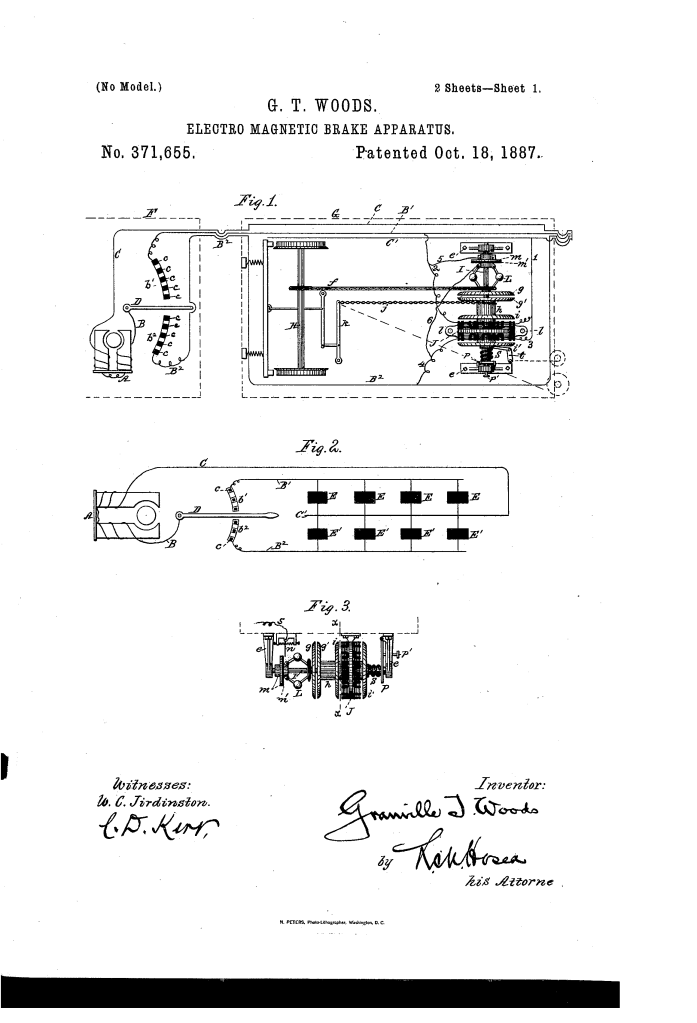

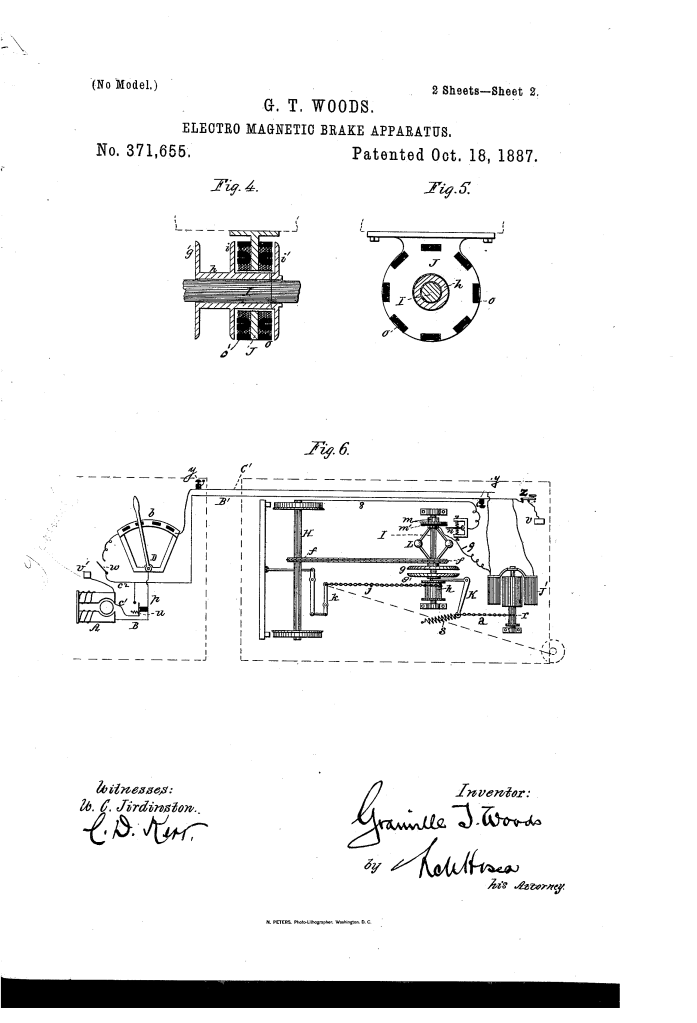

Electro-Magnetic Brake Apparatus (Granville T. Woods, No. 371655)

The patent by Granville T. Woods of Cincinnati, Ohio, describes a revolutionary Electro-Magnetic Brake Apparatus (Patent No. 371655, 1887). This invention provides a system for controlling railway brakes using electricity, allowing an engineer to set, regulate, or release brakes across an entire train simultaneously from the locomotive. By utilizing the rotational force of the car axles themselves to provide the physical braking power, Woods created an efficient and economical alternative to the manual or purely mechanical braking systems of the time.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910), often called the “Black Edison,” was one of the most prolific African-American inventors in history. He held over 50 patents, primarily focused on electrical systems for railroads and communications. This specific patent represents a significant leap in railway safety. Before automated systems like Woods’s, “brakemen” had to run along the tops of moving train cars to manually set hand brakes—an incredibly dangerous job that resulted in many deaths. Woods’s mastery of electromagnetism and circuit logic was so advanced that his designs were frequently challenged (unsuccessfully) in court by Thomas Edison himself.

Invention and Mechanism (Simplified)

The system works by using electricity to “clutch” the rotation of the moving car axle into a winding drum that pulls the brake chains.

1. The Power-Driven Counter-Shaft (I)

- Axle Drive: A counter-shaft (I) is mounted beneath each car. It is connected to the car axle (H) by a chain and sprocket ($f$).

- Function: As long as the train is moving, the counter-shaft is spinning.

- Friction Disks : A fixed disk spins with the shaft. A second, loose disk ($g’$) is attached to a winding drum.

2. The Magnet Structure (J) (Key Innovation)

- Dual Magnets: An annular structure (J) contains two sets of electromagnets facing in opposite directions.

- Setting the Brakes: When the “on” magnets are energized, they pull the armature of the winding drum, forcing the friction disks together.

- Function: The spinning shaft now forces the drum to rotate, winding up the brake chain and applying the brakes.

- Releasing the Brakes: When the “off” magnets are energized, they pull the drum in the opposite direction, disengaging the friction disks and releasing the tension on the chains.

3. The Centralized Control Switch (D)

- Resistance Switch: On the locomotive, the engineer operates a resistance-switch (D).

- Function: By moving the lever, the engineer can send a full current for an emergency stop or a partial current (using resistance coils for a gradual slow-down. This allows for precise control of the train’s speed without jerking.

4. The Safety Governor (L) (Anti-Lock Braking)

- Centrifugal Governor: Woods included a ball-governor (L) on the counter-shaft.

- Function: If the brakes are applied so hard that the wheels “skid” (stop rotating), the governor collapses. This triggers a contact switch that automatically shunts the current to the “release” magnets.

- Result: This creates an early form of Anti-lock Braking System (ABS), preventing the wheels from locking up and ensuring the train stops more safely and with less damage to the tracks.

Concepts Influenced by This Invention

Granville T. Woods’s brake apparatus influenced the fundamental safety and automation of the global rail network.

- Anti-Lock Braking (ABS) Logic: The core concept of using a speed-sensing device (the governor) to automatically reduce braking force when a wheel stops rotating is the direct mechanical ancestor to modern ABS found in every car today.

- Centralized Train Control: Woods helped pioneer the train-wide electrical bus, where a single signal from the front of the train manages complex mechanical actions at the rear. This is the foundation of modern “Electronic Controlled Pneumatic” (ECP) braking.

- Clutch-Based Power Take-Off: The method of using a magnetic clutch to “steal” power from a rotating shaft to perform secondary work (winding the brakes) is a principle used extensively in industrial machinery and automotive air conditioning compressors.

- Redundancy and Fail-Safes: His modified design (Fig. 6) used a spring-loaded fail-safe, where the brakes would automatically set if the electrical connection between cars was severed—a concept essential to modern “dead-man” safety systems.