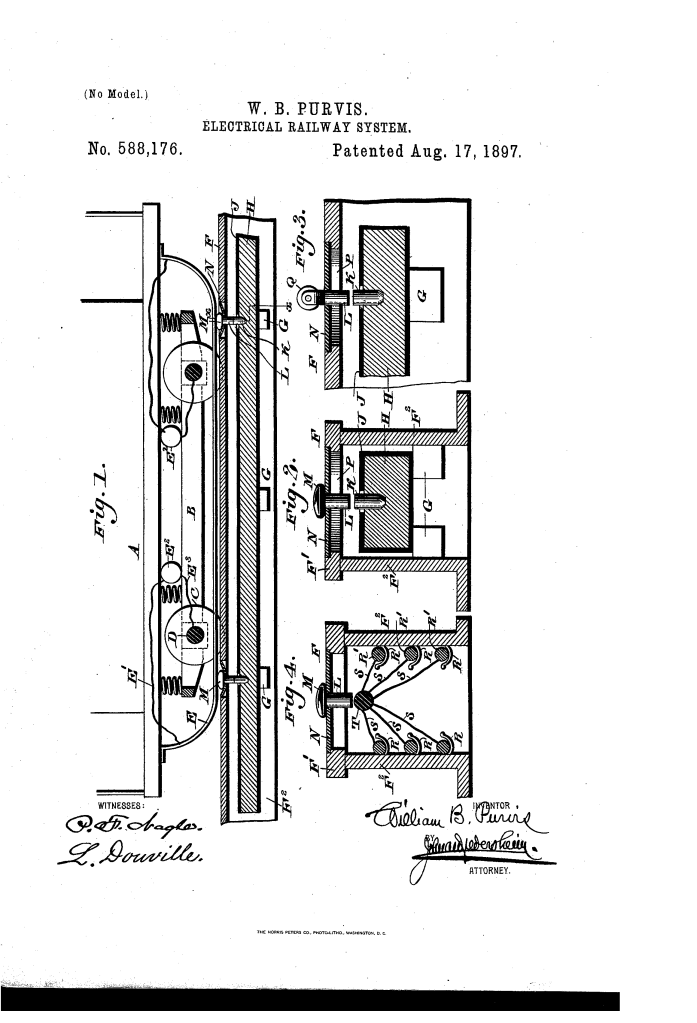

Electrical Railway System (William B. Purvis, No. 588,176)

The patent by William B. Purvis of Philadelphia, Pennsylvania, describes an Electrical Railway System (Patent No. 588,176, 1897). The invention focuses on a system for conducting electrical current to a car from an enclosed conduit using a series of closely spaced yielding contact devices and a resilient collector strip on the car. The key objective is to ensure that the electrical connection is automatically and effectively broken after the car passes each contact device, improving safety.

Inventor Background: William B. Purvis

William B. Purvis (1844–1929) was an exceptionally prolific African-American inventor who held numerous patents, largely related to railway safety, machinery, and electrical systems.

- Focus on Railway Power and Safety: Purvis had previously patented an entirely different magnetic system (No. 519,291) to power a rail car. This later patent shows his sustained effort to solve the problems of safe and reliable power transfer from underground conduits, with a strong focus on the safety requirement of sectional power control.

- The Problem Solver: Purvis consistently applied ingenuity to solve major industrial and transit challenges, solidifying his status as a key inventor in the late 19th-century industrial boom.

Invention and Mechanism

The system uses a resilient strip on the car to momentarily activate sectional contacts in the track conduit, which then immediately retract to kill the power in that section.

1. Conduit and Sectional Power

- Conduit (F): The conductor is housed in a conduit with a top (

) and depending sides (

). It is open at the bottom to allow water and moisture to escape.

- Main Conductor (H): The primary insulated feeder or conductor wire, supported inside the conduit.

- Movable Contact Pin (L): A series of these pins are arranged at intervals in the conduit top. Each pin is fitted with a diaphragm (N) of resilient material (rubber or equivalent) and is held out of contact with the main conductor (H).

2. Power Activation and Collection

- Resilient Contact-Strip (E): A yielding or resilient metal strip attached to the underside of the car, insulated from the car body. This strip is connected to the car motor (

).

- Operation: As the car progresses, the resilient strip (E) makes contact with the heads of the movable contact pins (L), depressing the pin (L).

- Connection: The depressed pin (L) is forced downward to make electrical contact with the stationary conductor (H) or with a series of stationary contacts (K) connected to the feeder.

3. Automatic Disconnection (Key Innovation)

- Automatic Break: As the car’s resilient strip (E) moves away from the contact pin (L), the resiliency of the diaphragm (N) forces the pin (L) immediately upward, breaking the electrical connection between the pin and the main conductor (H).

- Function: This ensures the electrical connection is effectively broken in every instance after the progression of the car. The current is only supplied to the segment of the conduit directly under the car, improving safety.

4. Modifications

- Roller Contact (Q): A modification replaces the simple head with a roller or wheel (Q) to minimize friction when the strip (E) passes over it.

- Auxiliary Feed Wires (R): A design using multiple auxiliary feed wires that lead to a single main conductor (T), maintaining the principle of sectional contact.

Concepts Influenced by This Invention

Purvis’s system influenced subsequent electric traction and safety designs by pioneering dynamic, pressure-actuated power transfer with immediate sectional cut-off.

- Sectionalized Power Rail (Safety): The core principle of powering only the segment of the conductor directly beneath the vehicle and instantly cutting power to the segment just passed is the fundamental concept behind modern sectionalized third-rail systems and other safety systems in urban transit (like subways and trolleys).

- Pressure-Actuated Contact: The mechanism of using the vehicle’s weight (via the resilient strip E) to mechanically depress and activate a track-side contact (pin L) influenced the design of various mechanical signaling trips and pressure sensors used in railways, where the physical presence of the vehicle initiates an action.

- Diaphragm/Spring Return Actuation: The reliance on a resilient diaphragm (N) to serve as the spring for the movable contact (L) is a simple, robust mechanical solution for automatic return and sealing. This principle is utilized in various safety valves, pressure switches, and self-sealing mechanisms where a flexible barrier is used to maintain a default position and seal.

- Resilient/Sliding Power Collection: The use of a resilient strip (E) that slides over the contacts influenced the design of current collection equipment, often emphasizing flexibility to maintain continuous contact despite minor track irregularities.